Metalworking Industry Sees Surge in Automation Adoption

While the basic steps in metalworking remain unchanged over the years, businesses increasingly rely on machines to complete them. While not unique to fabrication, this shift is seeing particular growth in the sector, so companies within the industry should pay attention.

Waste not, want not - rapid identification of metals in scrap

Handheld devices, such as XRF analyzers, offer recyclers tools to rapidly and accurately determine the composition and grade of incoming scrap. This eliminates the need to depend on traditional verification methods such as spark or chemical tests.

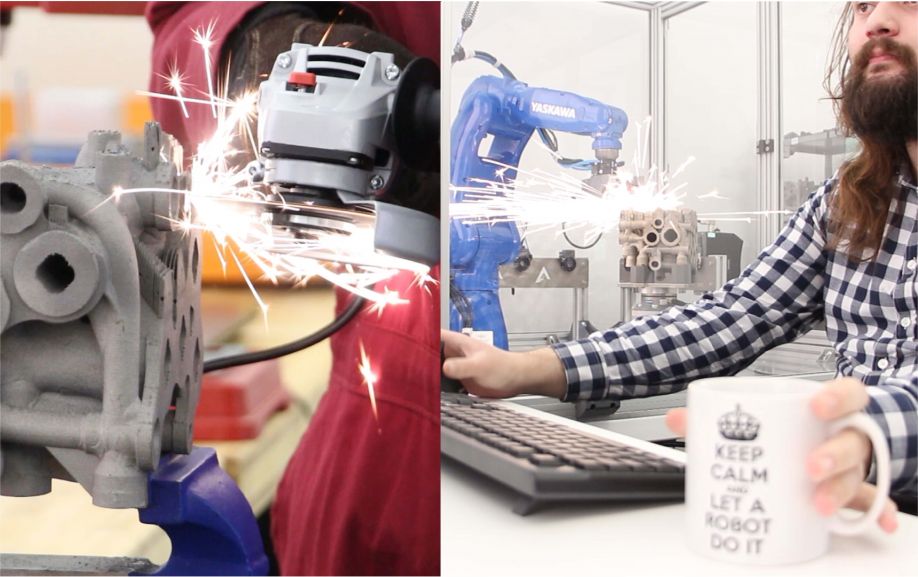

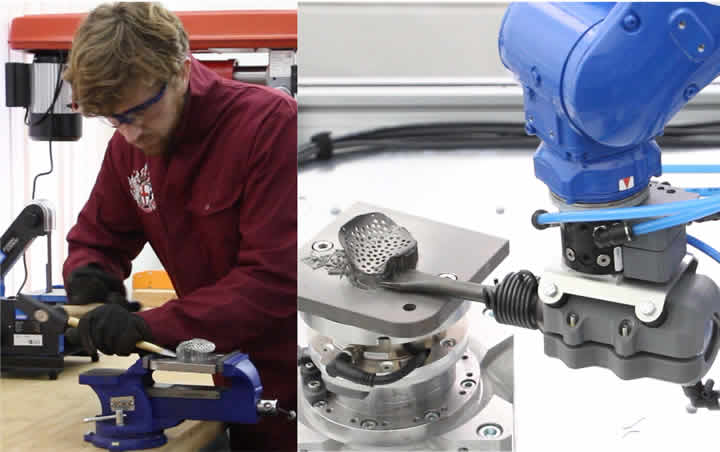

THE RISE OF AUTOMATION IN METAL AM POST-PROCESSING - TRANSFORMING THE INDUSTRY WITH PRECISION AND EFFICIENCY

We delve into how automation in metal AM post processing is setting a new industry standard, and how companies like Rivelin Robotics are leading this change with their Netshape® Robots to unlock new productivity and efficiency gains.

Why 3D Metal Printing Is Key to the Future of Aerospace Engineering

The aerospace industry constantly pushes the boundaries of what's possible, and the demand for advanced manufacturing techniques has never been more critical. This pursuit of innovation has led to a significant shift toward 3D metal printing.

CLEANING UP AM'S DIRTY SECRET

The fact that post processing metal parts requires such intensive manual intervention throws up a series of follow-on problems. These include part-to-part quality inconsistencies, repetition fatigue, significant health & safety risks.

Metal Additive Manufacturing Launches Learning Experience on Rocket Turbopump Design

All eyes are on metal AM to reach the ideal of single-part rocket construction, where as many parts and sections as possible are combined for material integrity, maximum weight reduction, performance, and speed-of-manufacture.

Enhanced Quality Control and Post Processing for Metal 3D Printing

Metal 3D-printed parts can be produced at higher production rates with impeccable quality by implementing advanced quality control and post-processing techniques.

Metal Additive Manufactured Parts for Racing Car

In metal powder bed fusion process the quality and of the powder raw material are of paramount importance, as the process relies on thin layers of metal powder being deposited and melted to produce metallic parts.

Relativity Space Maps Path to Terran R Production at Scale With Unveil of Stargate 4th Generation Metal 3D Printers

Relativity Space's Stargate 4th Generation 3D metal printers, capable of horizontally printing objects up to 120ft long and 24ft wide at as much as 12x faster than its predecessor.

Metal 3D Printing Promotes Revolution in Valve Design and Manufacturing

The emergence and mature applications of metal 3D printing technology, as well as intelligent software such as CFD and CAE, are driving and leading new changes in valve design and manufacturing.

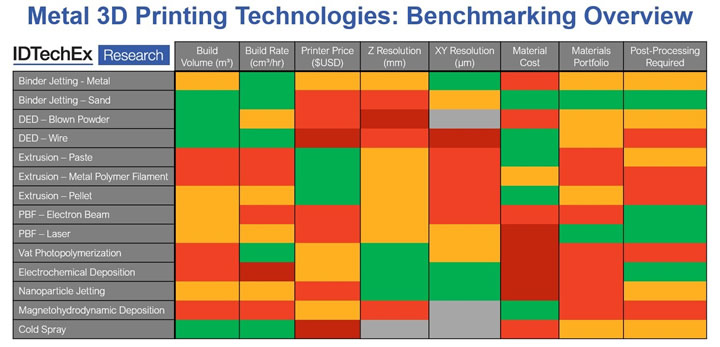

Metal 3D Printing Technology Landscape - IDTechEx Outline The Trends and the Whitespaces

Through an extensive benchmarking study, IDTechEx has asked the question: where are metal additive manufacturing technologies going, and where are the whitespaces for advancement in the metal AM landscape?

Benchmarking Photo Chemical Etching for Precision Metal Applications

The unique characteristics of PCE overcome many of the issues associated with more traditional metal cutting technologies, and as such - in some instances - when looking for a cost-effective solution for the manufacture of precise metal parts, it is the only viable choice.

How Will Labor Shortages Impact Metal Fabrication in 2022?

The American Welding Society estimates a 400,000-worker shortage by 2024. The urgent need for more welders and higher skill levels among welding personnel is widely known and accepted in the U.S. manufacturing industry.

Case Study: Keselowski Advanced Manufacturing (KAM)

Laser Powder Bed Fusion (L-PBF) is central to its production of metal additive manufacturing (AM) parts. In this process, lasers melt and weld layers of metallic powder resulting in parts that are durable and can be polished.

Improving the Performance of Supercritical CO2 in Next-generation Energy Applications with 3D Metal Printing

Mohawk Innovative Technology uses VELO3D's metal AM system to develop a high temperature heat transfer fluid circulator for the Department of Energy

Records 1 to 15 of 36

Featured Product

OnLogic Karbon 520 Series of Scalable Rugged Computers

The OnLogic Karbon 520 Series of rugged computers is purpose-built to deliver unwavering performance and reliability in the face of extreme temperatures, vibration, and dynamic power conditions. Powered by the latest Intel® Core™ Ultra processors and validated by MIL-STD-810H testing, the Karbon 520 Series makes it possible to deploy dependable computing for AI at the edge, advanced automation, or critical remote and in-vehicle applications in even the most challenging environments.

Manufacturing and Automation - Featured Company

ResinDek / Cornerstone Specialty Wood Products

At Cornerstone Specialty Wood Products®, we know and understand the importance of having the right flooring product for the right application. That's why we offer a variety of ResinDek panels in different thicknesses, densities, and with different surface finishes. Since 1994, ResinDek flooring panels have been installed in distribution centers, warehouses, manufacturing plants, and cold storage facilities for major corporations worldwide. The intent of Cornerstone Specialty Wood Products then and now is "We don't just make better mezzanine floors"¦We make mezzanine floors better". We strive to provide solutions that improve the ergonomics in work environments, reduce environmental impacts, and bring significant value to the professionals in many different industries.

.png)

.jpg)

.png)

.jpg)