New Technology Uses CNC to Drop Metal 3D Printing Costs

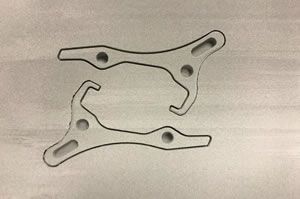

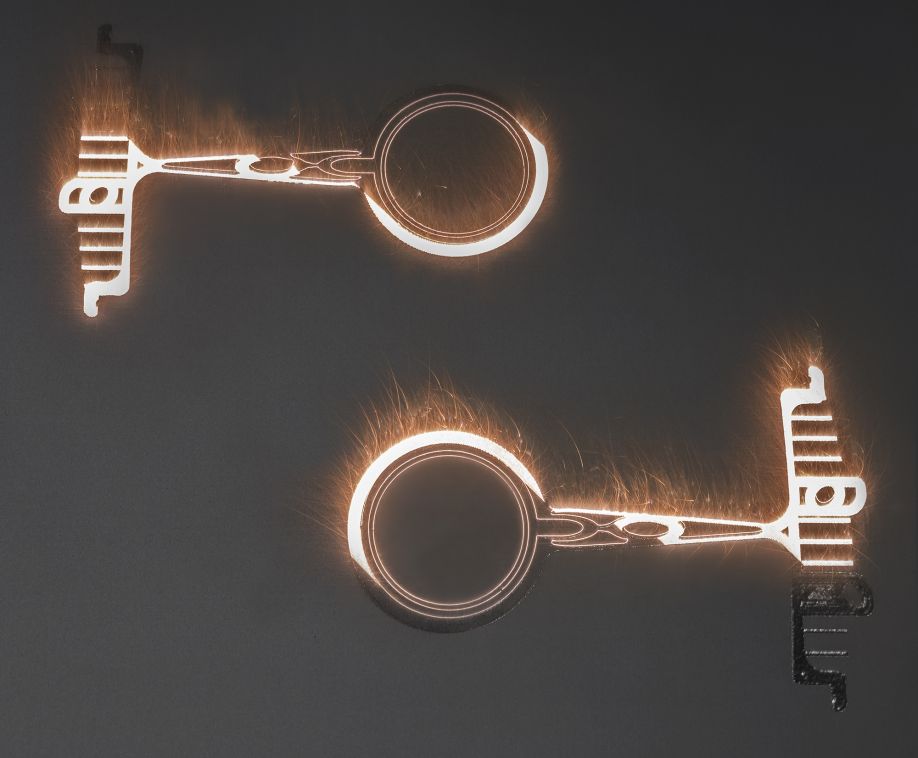

Michael Molitch-Hou for Engineering.com: 3DEO, based in Los Angeles, Calif., may have found a method for dropping metal AM costs even further.

GE Is Building The World's Largest 'Additive' Machine For 3D Printing Metals

The production version, still to be named, will extend the third dimension to a meter. GE Additive said the machines "build geometry will be customizable and scalable for an individual customers project. Its feature resolution and build-rate speeds will equal or better todays additive machines."

Volkswagen Taps Ultimaker for Customized Tool Production

By 3D Printing Gauges, Jigs and Fixtures On-Demand and On-Site, Manufacturing Facility Saves an Average of Eight Weeks in Production

GE Additive creating world's largest laser-powder additive machine

"The machine will 3D print aviation parts that are one meter in diameter, suitable for making jet engine structural components and parts for single-aisle aircraft"

PRODWAYS GROUP PRESENTS ITS NEW RAPID ADDITIVE FORGING TECHNOLOGY FOR THE 3D METAL PRINTING OF LARGE PARTS

On the eve of Le Bourget Paris Air Show, Prodways Group, a subsidiary of Groupe Gorg©, presents its new RAF Technology (Rapid Additive Forging) for the 3D metal printing of large titanium parts.

Fisher Unitech Partners with Desktop Metal to Provide Breakthrough Metal 3D Printing Solutions

Affordable, safe, fast, and precise metal 3D printing for bothprototyping and mass production

Records 31 to 36 of 36

Featured Product

Quality assurance in the manufacturing industry

Efficiency and precision with CSP software. In the highly competitive world of manufacturing, quality assurance is a critical factor for success. CSP offers you state-of-the-art software solutions specifically designed to ensure the highest standards of quality assurance in the manufacturing industry.

Manufacturing and Automation - Featured Company

PI USA (Physik Instrumente)

PI is a privately held company that designs and manufactures world-class precision motion and automation systems including air bearings, hexapods and piezo drives at locations in North America, Europe, and Asia. The company was founded 5 decades ago and today employs more than 1700 people worldwide. PI's customers are leaders in high-tech industries and research institutes in fields such as photonics, life-sciences, semiconductors and aerospace.