3D Printing Produces Engine Covers To Accelerate Aircraft Maintenance

How a specialized local engineering company supported a major airline during the pandemic with jet engine covers made with 3D printed molds.

Why 3D Metal Printing Is Key to the Future of Aerospace Engineering

The aerospace industry constantly pushes the boundaries of what's possible, and the demand for advanced manufacturing techniques has never been more critical. This pursuit of innovation has led to a significant shift toward 3D metal printing.

The Sky's the Limit: Additive Manufacturing in Aerospace Will Soar with Parts Certification

The introduction of a wide range of materials, including high-temperature materials, is enabling production of flightworthy parts capable of withstanding extreme conditions, like temperatures over 350F.

Relativity Space Maps Path to Terran R Production at Scale With Unveil of Stargate 4th Generation Metal 3D Printers

Relativity Space's Stargate 4th Generation 3D metal printers, capable of horizontally printing objects up to 120ft long and 24ft wide at as much as 12x faster than its predecessor.

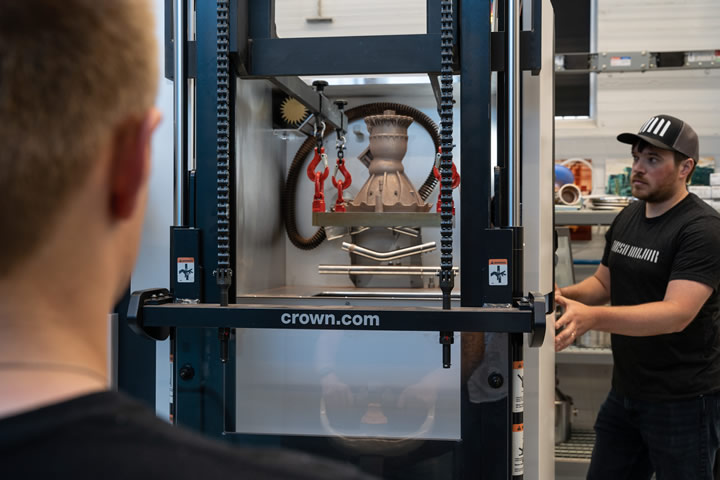

Rocket Propulsion Company's 3D-Printing Lab Delivers First Rocket Engine Components

Ursa Major's Advanced Manufacturing Lab in Youngstown, Ohio Cuts Time to Produce Rocket Engine Components from 6 Months to 1 Month

2021 Top Article - Additive in Space - Cost Reduction in Aerospace Through Additive Manufacturing

The elements needed for space travel do not have to meet the high launch requirements, but can be tailored precisely to the mission requirements. The process is being researched on parabolic flights in zero gravity - supported by a uEye CP industrial camera from IDS.

When Products Fail

Spectacular failures tend to attract much attention. It is simple curiosity as to why it happened and why something was not done to prevent it. One such event was the engine fire on a Boeing 777 flight over Denver in February 2021.

MAKING FASTER FLIGHT MAINTENANCE POSSIBLE

Satair, an Airbus services company, wanted to expedite aircraft maintenance through on-demand tools manufacturing. Fast Radius worked with Satair to deliver an innovative multi-process manufacturing solution that has the potential to transform the aerospace market.

ADDERE REDUCES THE PART COUNT IN LARGE SCALE ASSEMBLIES

"It's so rare that we get to show some of the capabilities we have, especially one that has gone through finish machining, says Scott Woida, President ADDere, "I think it gives a new perspective to what is possible with the technology."

Successful Mission of TuPOD, 3D Printed Innovative CubeSat

There is no doubt that 3D Printing is shaping our societies. Its future is evolving very fast and, although its impact on different sectors is still to be defined, many industries are leveraging 3D Printing technologies for their goals.

Success: 3D Bioprinter in Space Prints With Human Heart Cells

A 3D bioprinter privately owned by an American company has successfully printed with a large volume of human heart cells aboard the International Space Station (ISS) U.S. National Laboratory.

Automating Assessments in A&D for Improved Quality

Using digital twin and digital thread technology, A&D manufacturers can conduct automated assessments to analyze the performance of aircraft components - an advancement that has significant implications for the industry.

Building Optical Assemblies for Commercial Space Applications - Key Supplier Selection Criteria

The requirement for reliability and precision is especially the case when looking at space/earth imaging devices, which must be rugged, produce exceptional results, while at the same time being competitively priced.

Case Study: Phase Four Launches Scalable Electric Propulsion (EP) System with Xometry

This innovative California-based aerospace company is revolutionizing space exploration with Maxwell, its mass-producible EP system. Xometry is the manufacturing platform that's bringing its exoskeleton from its 12-page drawing to life.

Providing Precision to Power Aerospace Engines

Over recent years, a wide range of advanced machine tools have been developed to help satisfy global aerospace manufacturing industry's requirement to produce parts faster than ever before.

Records 1 to 15 of 30

Featured Product

BigRep ONE: Large-Scale 3D Printing

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 350 systems installed worldwide, it's a trusted solution for prototyping and production by designers, innovators, and manufacturers alike. Featuring a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

.jpg)