Blue-collar workers interact daily with machines, materials, and processes, giving them a unique vantage point. Yet in many plants, their voices go unheard because reporting issues is slow, informal, or buried under paperwork.

Giving Blue-Collar Workers a Voice in Problem Solving — Without Slowing Production

Article from | Orca Lean

In every factory, the people who spot problems first aren’t the executives or managers — they’re the operators on the shop floor. Blue-collar workers interact daily with machines, materials, and processes, giving them a unique vantage point. Yet in many plants, their voices go unheard because reporting issues is slow, informal, or buried under paperwork.

This silence costs manufacturers dearly. Problems that could have been addressed early escalate into bigger issues — lost output, higher scrap, delivery delays, or even safety incidents. The challenge is simple: how do you give workers a structured voice in problem-solving without slowing production down?

The answer lies in digitizing the SQDC dashboard.

Why Operators’ Voices Matter?

Operators are the “sensors” of the production system. They see everything:

- A strange vibration in a machine that signals future downtime.

- A batch of raw materials that feels inconsistent.

- A recurring defect that quality checks may miss until it’s too late.

Yet, traditional reporting methods don’t capture these insights effectively. Whiteboards, sticky notes, or verbal mentions during shift huddles are fragile systems. By the time the issue makes its way to management, hundreds of defective units might already be produced.

.png)

Barriers to operator input include:

- Fear of slowing production or being blamed.

- No structured platform to log issues in real-time.

- Feedback buried in meetings, emails, or Excel sheets.

The result is hidden costs: recurring rework, warranty claims, and frustrated teams. Studies show that up to 70% of problems in factories are first detected by front-line operators — but without a system to act quickly, these warnings get lost.

A digital SQDC for factory teams ensures operators’ voices are heard and converted into actionable insights.

The Tension: Empowerment vs. Production Flow

Many managers hesitate to empower operators fully because they fear production will stall. If every operator stopped the line for every issue, daily output would crash. On the other hand, if concerns are ignored or delayed, recurring problems multiply.

In traditional SQDC boards:

- Operators raise issues, but updates wait until the next daily management meeting.

- Paper-based escalation is inconsistent across shifts.

- Accountability is vague, leaving operators feeling ignored.

Scenario: An operator spots a misalignment in packaging. Without digital escalation, the issue waits until the next SQDC review. By then, dozens of boxes are mislabeled, creating rework and shipping delays.

The challenge is finding a balance: empowering workers without disrupting the flow. This is where a digital SQDC dashboard proves its value.

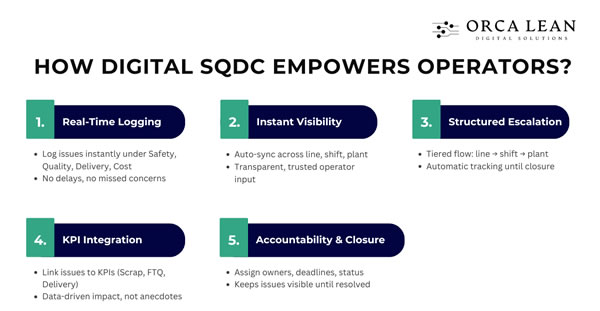

How Digital SQDC gives Blue-Collar Workers a Voice in Problem Solving?

A digital SQDC system like FactoryKPI SQDC transforms the daily management process by making problem reporting fast, structured, and visible.

1. Real-Time Issue Logging

In traditional setups, operators wait until shift-end meetings or scribble issues on whiteboards. With a digital SQDC dashboard, concerns are logged the moment they appear on the shop floor. This immediacy ensures problems don’t slip through cracks, allowing faster response times and minimizing costly delays in quality, safety, or delivery.

- Log concerns instantly under Safety, Quality, Delivery, or Cost.

- No waiting for meetings or manual updates.

- Faster reaction = reduced hidden costs.

2. Instant Visibility Across Levels

Once logged, issues appear immediately on the manufacturing dashboard, making them visible to supervisors and team leaders in real time. Instead of bottlenecks forming due to communication delays, everyone responsible sees the same information. This transparency ensures that corrective action can be prioritized without slowing production flow.

- Issues auto-sync to dashboards at line, shift, or plant level.

- Visibility ensures no “forgotten” concerns.

- Builds trust by making operator input visible instantly.

3. Structured Escalation

Paper SQDC boards often create confusion: who owns the problem, and when will it be solved? A digital SQDC for factory teams solves this with structured escalation. If an issue isn’t closed at line level, it flows automatically upward, ensuring accountability without overwhelming managers or halting operations.

- Tiered escalation: line → shift → plant level.

- Automatic tracking until issue closure.

- Prevents recurring problems from being ignored.

4. KPI Integration and Tracking

Every issue logged connects directly to KPIs such as scrap rate, FTQ (First-Time Quality), or on-time delivery. This makes problem-solving measurable, not anecdotal. Leaders can track whether actions taken actually improved performance, linking operator concerns to the company’s larger business outcomes.

- Link every issue to measurable KPIs.

- Spot patterns across shifts or suppliers.

- Provides a data-driven view of problem-solving impact.

5. Accountability & Closure

In manual SQDC systems, it’s easy for issues to remain “open” indefinitely, with no one taking ownership. With FactoryKPI SQDC, accountability is clear: each issue has an assigned owner, due date, and closure status. Operators see their input drive real results, while managers maintain oversight without micromanagement.

- Assign issue owners and deadlines instantly.

- Keep issues visible until resolved.

- Operators feel heard; managers gain control.

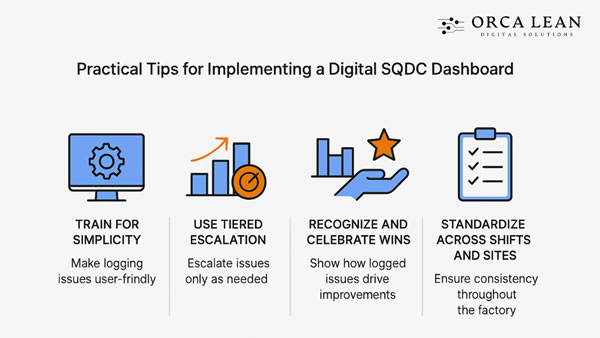

Practical Tips for Implementation

To fully unlock the value of a digital SQDC dashboard, factories need to focus on practices that make the system simple, consistent, and impactful.

1. Train for Simplicity

Operators should be able to log issues in just a few clicks. If the system feels like extra work, adoption will lag. A user-friendly, intuitive interface ensures reporting becomes second nature instead of a burden.

2. Use Tiered Escalation

Not every problem requires plant-level attention. Start with line-level dashboards and only escalate to higher levels when issues remain unresolved. This keeps the daily management process lean, while still ensuring visibility for critical concerns.

3. Link Issues to KPIs

Every logged problem should connect to measurable performance indicators — safety incidents, scrap rates, first-time quality, or delivery delays. This ensures that digital SQDC isn’t just a reporting tool but a driver of performance improvement.

4. Recognize and Celebrate Wins

When operators see how their logged issues lead to reduced downtime, fewer defects, or safer conditions, it builds trust. Recognizing these contributions — even in small ways — reinforces a culture of participation and continuous improvement.

5. Standardize Across Shifts and Sites

Consistency is crucial. Using the same digital SQDC framework across teams avoids variability, ensures fairness in tracking, and builds reliable data for leadership.

With these practices, a digital SQDC dashboard evolves from a simple recording system into a powerful continuous improvement loop — one that empowers workers, keeps managers accountable, and strengthens performance at every level of the factory.

FactoryKPI SQDC in Action

A digital SQDC dashboard turns operator feedback into structured, trackable action. Issues are logged instantly, made visible in real time, and tied to KPIs — ensuring problems are solved, not just discussed.

Example:

- Without Digital SQDC: An operator spots rising scrap, notes it on a whiteboard, and waits for the shift meeting. By then, dozens of defective units are produced, updates are forgotten, and the defect repeats.

- With FactoryKPI SQDC: The same issue is logged immediately, flagged on the dashboard, and assigned with clear accountability. Leaders see the trend, fix the root cause, and prevent recurrence.

Impact: Scrap is reduced, accountability is enforced, and operators feel heard — driving a culture of continuous improvement without slowing production.

Conclusion

Factories thrive when the people closest to the process — the operators — have a voice in problem-solving. The risk has always been slowing production. But with a digital SQDC dashboard, manufacturers can achieve both: empowerment without disruption.

FactoryKPI SQDC bridges this gap. It allows operators to raise issues instantly, ensures managers act quickly, and connects everything to KPIs. The result? Safer operations, higher quality, on-time delivery, and stronger margins — all while building a culture where every worker matters.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product