In an environment driven by Lean Manufacturing and Continuous Improvement, AI empowers shops to act faster and smarter, without adding more headcount.

AI in Manufacturing: Why Now Matters

Article from | Datanomix

Operators are hard to find. Engineers are maxed out. Delivery expectations aren’t getting any easier. For most precision manufacturers, the challenge isn’t “too little data”, it’s too few people and too little time to act on what that data is actually telling them. That’s why now is exactly the right moment to talk about AI in manufacturing, not as hype, but as help.

In an environment driven by Lean Manufacturing and Continuous Improvement, AI empowers shops to act faster and smarter, without adding more headcount.

The Real Problem Isn’t Data — It’s Time

Over the past decade, manufacturers have improved their ability to collect data. With advances in CNC machine monitoring, process analytics, and ERP integrations, it’s now possible to track everything from spindle uptime to part counts to tool life.

But here’s the kicker: data access isn’t the problem anymore — time is.

Skilled operators don’t have time to comb through reports. Manufacturing engineers don’t have hours to babysit a machine, waiting for subtle shifts in vibration or temperature that might predict a bad part. Managers don’t have the bandwidth to chase every signal that could impact part quality, delivery dates, or job costing outcomes.

As Greg McHale put it on the Buy the Numbers podcast:

“The bottleneck has shifted from collection to interpretation. AI is how we cross that gap — not by replacing people, but by giving them back the time to focus where it matters most.”

Datanomix AI Shows Up Where It Counts

At Datanomix, we’re focused on building AI into our Data-Powered Production™ software solutions that fit seamlessly into your day, on the manufacturing floor, in the process, and at the point of decision.

Our goal is simple: Use AI to reduce the burden on your team and amplify their ability to make smart, timely decisions. Here’s how we’re doing it:

FactoryMate™- AI That Thinks Like a Floor Supervisor

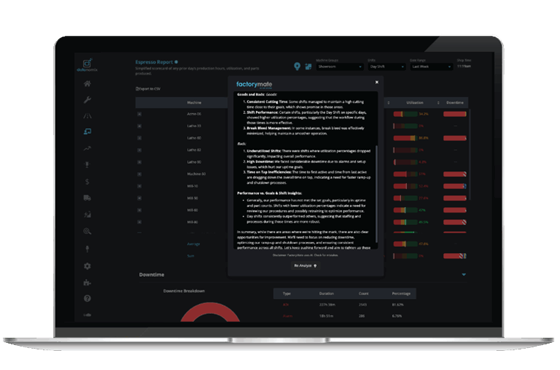

FactoryMate in the Espresso Report

In our simplified scorecard of any prior day’s production performance, FactoryMate will focus on the key areas: uptime, part counts, and the time on tap metrics—first active, last active, and break bleed. It will share both the good and bad news, provide an overall shift performance, and recommend areas for improvement.

FactoryMate is an intelligent agent that helps guide real-time shop decisions. It’s like a digital floor supervisor — always on, always ready.

- Simplified Report Analysis, Meeting Prep, Gemba Walk, and Decision Support

FactoryMate reads production reports and highlights actionable insights for supervisors and operators. It flags improvement opportunities, cycle time anomalies, or recurring bottlenecks. No digging, no guesswork, just next steps and how to get better — the kind that drive effective Gemba walks, Kaizen events, and real-time decision support for better deployment of people, jobs, and machines. - Smarter Job Tracking and Production Scheduling

Leveraging universal ERP connectivity and best-in-class machine data, FactoryMate evaluates all running jobs versus their On-Time Delivery targets to help manufacturers with job tracking, labor tracking, and production scheduling. FactoryMate evaluates real performance vs. targets, makes predictions about Delivery Dates, and provides guidance on how to improve On-Time Delivery. - G-Code Error Checking & Annotation

FactoryMate is also able to behave as an AI-Powered G-code editor — scanning files for issues or omissions, annotating them to reduce mistakes and close training gaps, creating clean G-code lists, and flagging potential errors before they impact part quality or process control.

In short: FactoryMate™ helps your team think one step ahead, without slowing them down.

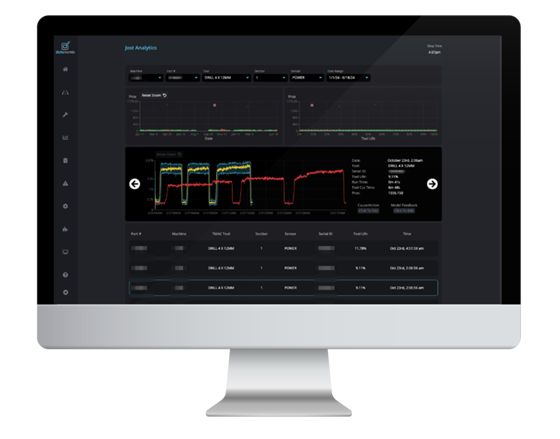

TMAC ai Jost Analytics

TMAC AI delivers predictive Insights into three key areas of production:

Quality, Tool Life, and Cycle Time.

TMAC ai™ – Predictive Quality That Prevents Surprises

Developed in partnership with Caron Engineering, TMAC ai applies artificial intelligence (AI) to high-resolution machine data — spindle load, vibration, and tool wear — to detect issues before they lead to scrap, rework, or broken tools.

It supports smarter decisions in process control and quality management:

- Is that likely to be a good part?

- Are we running close to a tool failure?

- How should we adjust TMAC settings to avoid downtime?

And the best part? It happens behind the scenes, analyzing signals and surfacing clear guidance only when something needs attention. TMAC ai helps supercharge engineers and operators alike by predicting scrap, predicting tooling issues, and doing real-time process control on critical sensor data right from your machines. Using AI in this manner to direct critical resources at critical problems is a great example of augmenting existing team members and reducing the time it takes to resolve problems.

As Rob Caron said:

“We’re not asking engineers to become data scientists. We’re bringing AI to where the work is — to the machine, to the process, and the decision.”

A Portfolio of AI That Adds Up to More Time, Less Stress

At Datanomix, AI isn’t a buzzword; it’s a precision tool.

Each application is designed to solve a specific problem right now, while opening the door to solving more complex ones later. Whether you’re focused on Lean Manufacturing, better Kaizen events, production monitoring, or G-code management, it all comes back to one thing:

Giving your team the time and focus to do what they do best.

And in today’s environment, where people are hard to find and expectations never let up, that’s the edge manufacturers need.

Datanomix delivers AI solutions that solve real problems and integrate seamlessly into existing workflows, such as Gemba Walks and Kaizen events, focusing on improving critical metrics, including OEE, Quality, Tool Management, On-Time Delivery, and Process Capability. This is because when AI works the way manufacturing does, everyone wins.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Datanomix

Datanomix empowers manufacturers of all sizes to increase productivity and profitability through its Data-Powered Production™ solutions. Its product portfolio includes Production Monitoring, G-Code Cloud™ + DNC, TMAC AI™, and ToolAnalytix™ - all designed to turn machine data into actionable insights with zero operator input. Headquartered in New Hampshire, Datanomix software analyzes real-time production signals to identify bottlenecks, improve quality, and provide prescriptive coaching to drive continuous improvement. For more information, visit www.datanomix.io.

Other Articles

How Flying S is Turning Data into a Competitive Advantage

Building a Culture of Team Performance at Paramount Machine with Production Monitoring

More about Datanomix

Featured Product