Case Study from Nord - A Heavy Lift

How OMi Crane Systems works with NORD DRIVESYSTEMS to keep manufacturing moving. For OMi Cranes and its customers alike, having a reliable drive system supplier isn't just about convenience, it's about keeping material moving efficiently and without fail.

NewsFender's 3D Printed Ballistic Fender Charts a New Course in Maritime Defense

Discover how NewsFender's 3D printed customizable, eco-friendly fenders and boat parts are making waves in the maritime defense industry.

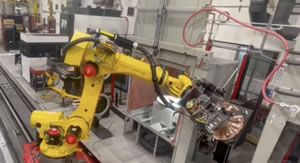

Transforming High-Precision Manufacturing through Advanced Automation

Honeywell faced growing demands for their high-precision manufacturing processes, coupled with labor shortages and strict quality standards. Their manual processes were becoming the limiting factor-causing bottlenecks, inconsistent quality, and increased scrap.

Renishaw helps Tronosjet Manufacturing achieve FAA certification

Renishaw supplied multiple laser powder bed fusion (LPBF) AM systems, which Tronosjet uses to produce various aircraft components.

How a Candle Maker Grew from the Kitchen Table to 7 Figures

With 70% of their business taking place during the holiday season, Fontana Candle Company relies on MRPeasy to ensure the timely production and delivery of their products. "I could never do it without MRPeasy," says Eric Roering, Founder and COO.

A Culture of Proactive Compliance

After establishing a compliance team, the reality of just how big a task this was set in. "As we started tackling it, first you get a couple of questions, then you get 20 questions, and then you realize this could be a full-time job, more than a full-time job.

Companies Collaborate to Build Giant Guitar Installation in Liverpool

Diamond Precision Engineering was tasked with making a giant guitar to mark the 80th birthday of Sir Paul McCartney.

Additive at Scale Uses Essentium Technology to Create an Asset Tracking Solution in 60 Days

Using the Essentium High Speed Extrusion (HSE™) 180 ST 3D Printing Platform and Essentium PCTG-Z, Additive at Scale partnered with Blues Wireless to design and manufacture 100 pilot units for an asset tracking solution for a multinational chemical company in just 60 days.

Ryvid's Anthem EV Bike Races Through Production With Xometry's Horizontal Supply Chain

Discover why this innovator in the micromobility powersport space chose Xometry to produce 50% of parts found in its flagship electric motorcycle, the Ryvid Anthem.

Case Study: Keselowski Advanced Manufacturing (KAM)

Laser Powder Bed Fusion (L-PBF) is central to its production of metal additive manufacturing (AM) parts. In this process, lasers melt and weld layers of metallic powder resulting in parts that are durable and can be polished.

MAKING FASTER FLIGHT MAINTENANCE POSSIBLE

Satair, an Airbus services company, wanted to expedite aircraft maintenance through on-demand tools manufacturing. Fast Radius worked with Satair to deliver an innovative multi-process manufacturing solution that has the potential to transform the aerospace market.

ERIKS: Working Clean, Certified, and in Control with 3D Printing

ERIKS offers technical components and related services to all sections of industry. And by adding 3D printing technology to its workflow, ERIKS is able to provide its customers with a service that holds the potential to shake up industries around the globe.

Red Lion Case Study - Kaleesuwari

Kaleesuwari were unable to receive real-time data from the 24 line machines operating in their plant, and therefore no accurate data was being collected on production output.

30 Days to Profitability for CCO's Plastics Client

Challenged with extraordinary delivery and quality issues, a plastics producer turned to Cornerstone Consulting Organization (CCO) to lead an aggressive operation recovery effort.

Case Study: BMW Uses Xometry's Range of Technologies to Make Custom Assembly Tooling

BMW tooling engineers can use Xometry's CNC machining, 3D printing, and urethane casting for custom assembly fixtures, which allows the company to put the finishing touches on its vehicles quickly and cost-effectively.

Records 1 to 15 of 50

Featured Product

The Wire Association International (WAI), Inc.

The Wire Association International (WAI), Inc., founded in 1930, is a worldwide technical society for wire and cable industry professionals. Based in Madison, Connecticut, USA, WAI collects and shares technical, manufacturing, and general business information to the ferrous, nonferrous, electrical, fiber optic, and fastener segments of the wire and cable industry. WAI hosts trade expositions, technical conferences, and educational programs.

Manufacturing and Automation - Featured Company

The Wire Association International, Inc. (WAI)

The Wire Association International (WAI), Inc., founded in 1930, is a worldwide technical society for wire and cable industry professionals. Based in Madison, Connecticut, USA, WAI collects and shares technical, manufacturing, and general business information to the ferrous, nonferrous, electrical, fiber optic, and fastener segments of the wire and cable industry.

WAI hosts trade expositions, technical conferences, and educational programs.