Discover how NewsFender's 3D printed customizable, eco-friendly fenders and boat parts are making waves in the maritime defense industry.

NewsFender's 3D Printed Ballistic Fender Charts a New Course in Maritime Defense

NewsFender's 3D Printed Ballistic Fender Charts a New Course in Maritime Defense

Case Study from Natasha Mathew for | BigRep

Fenders are an essential part of every vessel in the maritime world, yet their design hasn’t witnessed much change over the decades. A boat fender is a polyurea-coated foam barrier that protects a vessel’s hull from scratches and impact while maneuvering through marinas, and it has long been made through a slow, labor-intensive process. Manufacturing a single fender could take days, exposing workers to toxic materials such as isocyanates, petroleum-based foams, and polyurea. Despite the effort, these fenders offer little room for design variation or improvement.

NewsFender, a company based in Barcelona, is changing that. It is the first in the world to offer custom-made 3D printed ballistic fenders. They also design and manufacture eco-friendly boat fenders for shipyards, RIB boat builders, military patrol boats, coast guard patrol boats, police boats, and rescue boats with 9 large-scale BigRep 3D printers. 3D printing these parts requires just 3% of the energy used in traditional manufacturing. The result: durable, recyclable fenders with a lifespan of up to 20 years.

We sat down with Fernando Fortunato, NewsFender’s CTO, to unpack how he and his team are reengineering the fender and boat parts with 3D printing.

What NewsFender Does Differently

The maritime industry has relied on foam coated with polyurea, a petroleum-based material, for a very long time. The problem with polyurea is that while working with it, extensive precautions must be taken; otherwise, it can irritate the lungs, skin, and eyes. It takes a team to work in these conditions for days, and these fenders are not recyclable.

To address this, NewsFender developed a recyclable Maritime Elastomer. Using large-format BigRep 3D printers, NewsFender produces fenders that allow for unlimited customization, from flexibility in firmness levels to colors, textures, and any other custom requests.

.jpg)

3D printed fenders for NewsFender’s client, Victum Boats from Sweden.

Every fender is modular in design with interlocking one-meter parts that fit together perfectly like pieces in a puzzle. A fender has different levels of hardness, which is achieved by adjusting the infill. The front part of the fender, which is a high-impact zone, is softer to absorb shock, while the inner layers are harder.

Rescue fleets and police boats, which often collide during operations, have seen major benefits. Instead of replacing entire fenders, only damaged sections are replaced. This allows quick and easy maintenance where only the damaged section needs replacement.

Customizable 3D Printed Fender Options

1. NFC Chip Integration: Fenders can be customized with NFC chip which includes information such as origin, time of production, and ownership. If a fender is lost at sea, it can be scanned with a phone to identify the owner.

2. Ballistic Fender: The ballistic version of the fender provides bullet-resistant protection.

3. Flame Retardant: The fenders are made with a flame-retardant recyclable Elastomers and offer reliable protection against heat and fire hazards.

4. Glow in the Dark: The fenders can be customized with UV-reactive materials that charge in the sunlight, illuminate at night, and are visible up to 20 nautical miles.

Safety and Certification

Their new 3D printed ballistic fenders are undergoing certification for NIJ Level II and IIIa armor protection:

Level II protects against medium-caliber handgun rounds, such as 9mm and .357 Magnum.

Level IIIa offers higher protection, capable of stopping .44 Magnum and 9mm submachine gun rounds, commonly used in close-range threats.

NewsFender is working toward Level IV certification by mid-2026, which would allow the fenders to withstand armor-piercing rifle rounds, the highest standard of personal and structural ballistic protection. They are also preparing to meet NATO certification requirements.

Beyond fenders, the company is also expanding into 3D printing other boat components.

Other Applications

1. Fenders for Ports

Designed for ports such as Port Olímpic in Spain, NewsFender’s wall-mounted fenders can be tailored to match the functional or aesthetic requirements of any port. Below are some examples of fenders with black and gold carbon fiber and chrome-like mirror finish.

2. Boat Components

NewsFender uses 3D printing at every possible opportunity for boat parts such as consoles, cushions or even the hull. The goal is to make every component customizable, durable, repairable, and environmentally responsible. The company is developing a special elastomer for seats and cushions that are ultra-light and UV-resistant to withstand years of sun exposure without degradation.

3. 3D-Printed Boats

A 3D printed miniature of a Rigid Non-Inflatable Boat (RNIB).

Rigid Non-Inflatable Boats (RNIB) are currently under development for special forces operations. They are completely airless, eliminating the need for inflatable tubes. The boat would be printed with full ballistic protection.

4. Research and Development

Another use for BigRep’s large-scale 3D printers is for prototyping and testing new boat parts to ensure they meet exact weight, strength, fit, and performance specifications.

An example shown here is a part of a 15-meter rescue ship’s fender. Engineers digitally simulated impacts of up to 40 tons to analyze stress distribution, infill density, wall thickness, and deformation before moving to physical testing.

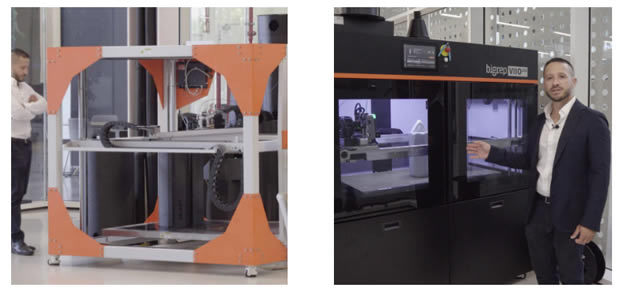

NewsFender’s Fleet of BigRep 3D Printers

At the heart of NewsFender’s operations is a fleet of nine BigRep 3D printers, forming the foundation of its production ecosystem. The company owns six BigRep ONE machines, two STUDIOs, and a VIIO 250. These machines run 24/7, printing around 500 kilograms each month, with plans to scale up to 700 kilograms as production expands.

The team also uses BigRep’s 3D printing software extensively. BigRep CONNECT for remotely monitoring print progress, transferring files, and accessing live camera feeds across facilities. BigRep BLADE software for easy slicing and workflow optimization.

Making Waves

3D printers and sustainable materials bring in a new way of thinking and manufacturing of how we build and protect the marine vessels. Looking ahead, Fernando Fortunato envisions 3D printers could be deployed directly on-board marine defense ships to produce spare parts from local or recycled materials. As the defense industry typically operates under strict confidentiality, in-house on-demand 3D printing provides security by keeping sensitive data on-site.

Natasha Mathew enjoys trying new things and one of them she’s currently obsessed with is 3D printing. Her passion for explaining complex concepts in simple terms and knack for storytelling led her to be a writer. In her 7 years of experience, she has covered just about any topic under the sun. When she’s not carefully weighing her words, she’s reading, crafting, spinning, and adventuring. And when asked about herself, she writes in the third person.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

BigRep

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep ONE opens the gateway to a new dimension of 3D printing and 3D manufacturing, while the BigRep STUDIO allows fast and precise large-scale 3D printing. From furniture to vehicles to robotics, we think everything is possible. We want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of our 3D printers.

Other Articles

BigRep ALTRA 280, the Ultimate High-Temperature Industrial 3D Printer

How 3D Printing is Paving the Way for Grading Contractor, C.J. Moyna & Sons

3D Printing Produces Engine Covers To Accelerate Aircraft Maintenance

More about BigRep

Featured Product