Rapid Prototyping Helps University Students Design Racing Car

Positioning Accuracy on the Gripper of a Robot Arm

Space Saving Modular Enclosure Solution Created To Separate and Protect Critical Components

MiR200 Improves Safety, Quality, and Competitiveness at Metro Plastics

Redefining Product Development Using Cutting-Edge 3D Metrology Solutions

GKN Aerospace Cuts Assembly Tool Production Time with Stratasys Additive Manufacturing

Service Bureau Business Doubles with Large Format 3D Print Capability

Hyundai Motors Improves Production Efficiency with Automation Software

Making Time for Holthinrichs Watches

The creation of the Force American Made (FAM) machine shop at John Force Racing (JFR) is a story about turning tragedy into triumph.

AI is Running this Smart Steel Mill

Russell Compact Sieve® skyrockets efficiency at New Balance additive manufacturing center

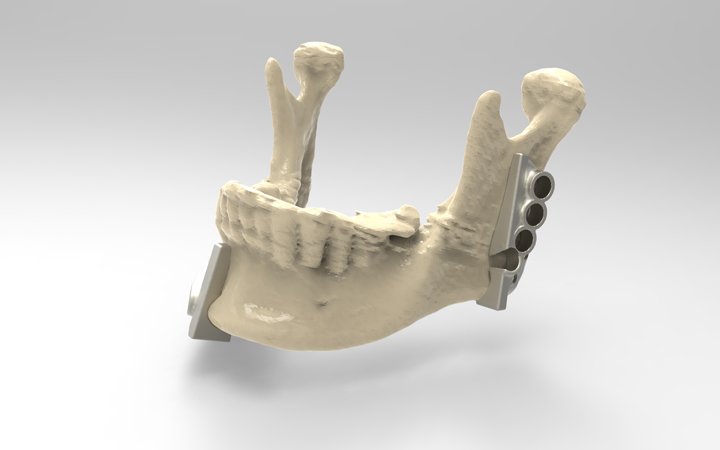

3d Modelling and Printing - Saving Theatre Time and Providing Excellent Patient Outcomes

Kerk Lead Screw Allows RPT Motion to Create Quick and Cost-Effective Case Packer

OESH Shoes - Manufacturing Story

Records 16 to 30 of 50

First | Previous | Next | Last

Featured Product

Quality assurance in the manufacturing industry

Manufacturing and Automation - Featured Company

.jpg)

.jpg)