3D Printing Will Soon Be a Game-Changer in the Manufacturing Industry. Here's Why

Xcentric Mold offers Resources to Keep Design Skills Sharp for the Ramp Up

Optimising Performance and Manufacturability for Additive Manufacturing

MICRO-MOLDING: KEY SUPPLIER SELECTON CRITERIA

Achieving Peak Performance in Elite Cycling and Beyond

Moving Beyond Prototypes

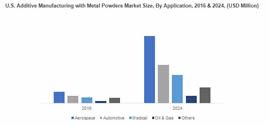

Additive Manufacturing with Metal Powders Market to surpass 4.5 kilo Tons Consumption By 2024

AREVO to Manufacture World's First 3D-Printed Carbon Fiber Unibody Bike Frames for New Line of eBikes from Franco Bicycles

University of Tampere and VTT to lead robotisation of SMEs with a total funding of EUR 32 million

Smart Utilization of 3D Printing Equipment and Materials Facilitates Continued Innovation

Developing a New Product Using Advanced Manufacturing Technologies

Carbon SpeedCell™: Additive Manufacturing Reinvented

Vaquform: The World's First Digital Desktop Vacuum Former

Keys To Developing A Successful Product Prototype

3-D-printed robots with shock-absorbing skins

Records 16 to 30 of 35

First | Previous | Next | Last

Featured Product

PI USA - High-Speed Hexapod for Nanopositioning

Manufacturing and Automation - Featured Company

.jpg)