The Way to Combine Metal and Plastic: Insert Molding

IM is a popular manufacturing process because it is fast and efficient. It also allows for a high degree of precision, meaning that products made using insert molding are typical of high quality.

Massachusetts Metalcaster Established Over a Century Ago Leaps Forward with 3D Mold Printing

A growing number of companies within the sand casting industry are adopting 3D sand printing to produce high quality parts without tooling. The technology to 3D print molds without changing the actual sand casting process itself is a major advancement for the industry.

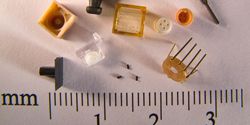

Risk Mitigation in Micro Molding

In applications where overall tolerances are measured in microns, there are various ways that micro molders mitigate the risks associated with each step of the design-to-manufacturing cycle.

MICRO-MOLDING: KEY SUPPLIER SELECTON CRITERIA

For companies that are exploring the possibilities that exist for miniaturization of plastic parts and components, there are some seemingly daunting obstacles that exist, not least the vagaries of the micro molding process itself.

Micro Molding - The Need for Collaboration and DfM

This article examines the ways in which companies looking to achieve significant product miniaturization need to approach their product development process, and how they need to adapt their thinking when embracing micro molding.

Manufacturers Replace Metal with Plastic to Reap Benefits of Plastic Resins While Maintaining Integrity of Metals

In today's fast-paced world there is an immense pressure on manufacturers to create a better, faster, stronger, cheaper product, and only those who are willing to adapt and innovate will survive. Manufacturers who've been dragging their heels (or worse, kicking & screaming) are now getting on-board with replacing metal parts with plastic ones.

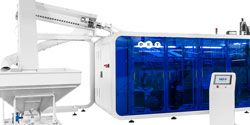

In-house Packaging Operations Propels Growth for Tropical Trade & Industries N.V.

New blow-molding equipment and custom bottle designs boost sales by 24 percent in a year for Caribbean syrup and essence manufacturer.

Case Study: Buying Time with 3D Printed Tooling

Imagine being able to produce short-runs of end use parts to test a concept or for direct use in just days. How would it feel to be able to bring a product to market faster than the competition?

Records 1 to 8 of 8

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

The FLIR Si1-LD is an easy-to-use acoustic imaging camera for locating and quantifying pressurized leaks in compressed air systems. This lightweight, one-handed camera is designed to help maintenance, manufacturing, and engineering professionals identify air leaks faster than with traditional methods. Built with a carefully constructed array of MEMS microphones for high sensitivity, the Si1-LD produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments. The acoustic image is overlaid in real time on a digital image, allowing you to accurately pinpoint the source of the sound, with onboard analytics which quantify the losses being incurred. The Si1-LD features a plugin that enables you to import acoustic images to FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation. Field analysis and reporting can also be done using the FLIR Acoustic Camera Viewer cloud service. Transferring of images can be managed via memory stick or USB data cable. Through a regular maintenance routine, the FLIR Si1-LD can help facilities reduce their environmental impact and save money on utility bills.

Manufacturing and Automation - Featured Company

Fronius Perfect Welding

We aspire to produce more than just welding systems, which is why we are the innovation leader for arc welding and are constantly developing welding processes further. In addition to welding technology for robot applications, we offer solutions for manual gas shielded arc welding, for MIG/MAG, TIG, and MMA welding processes. We also implement automated, complete welding solutions tailored to customer requirements in the field of welding automation. After all, welding creates connections - between metals, between industries, and between people. Connected by the arc, by passion, by the beat of welding.

.jpg)