Additive Manufacturing with Metal Powders Market to surpass 4.5 kilo Tons Consumption By 2024

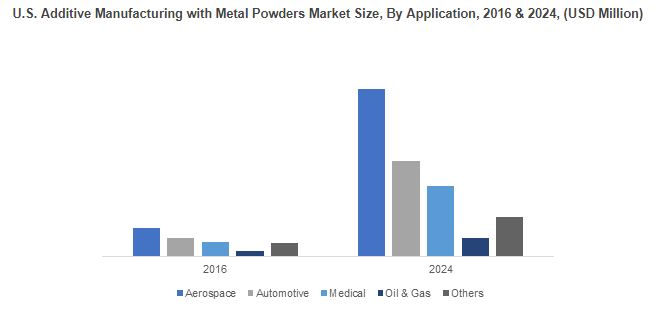

According to a new research report by Global Market Insights, Inc. Additive Manufacturing with Metal Powders Market is expected to USD 1.1 billion by 2024.

Increase in trend towards adoption of prototype has led to the development and validation of design faster along with reduction in production time & cost in various industrial sectors which has stimulated additive manufacturing with metal powders market demand. Increasing E&P activities in oil & gas sector has forced manufacturers for various technological advancements in 3D printing for efficient oil recovery, thereby propagating metal additive manufacturing market growth.

Positive application scope in aerospace industry in making engine, turbine parts and interiors should trigger additive manufacturing with metal powders market growth. Over 20% of aerospace engineering companies are using this technology to make tooling components. The industry is constantly putting effort to minimize aircraft weight by using lightweight metals such as stainless steel, titanium, aluminum, and copper. Growing trust for these technologies in aerospace firms, should minimize costs for developing models and prototypes, resulting in additive manufacturing with metal powders market growth.

Additive manufacturing with metal powders market size from oil & gas application is likely to be valued at over USD 45 million over the projected timespan. Prototyping and modelling for exploration and operational equipment, chemical injection stick tools, gears, impellers, pipeline rigs, nozzles for downhole cleanout tools, control valve components, large scale downhole tools and sealing accessories including O rings are produced through 3D printing which are used in the industry.

U.S. additive manufacturing with metal powders market size may exceed USD 400 million during the forecast timeframe. Growing health concerns, ageing population and long track of chronic disease coupled with strong regulatory regimes regarding medical device industry should propel regional demand. Improvement in long-term patient outcomes for surgeries and treatment along with growing oral rehabilitation demand should surge technology growth in the region.

Stainless steel, aluminum, cobalt, nickel and titanium powders are the prominent raw materials used in the additive manufacturing with metal powders method. Infringement law issues regarding the product and the technology along with volatility in regional raw material prices may impact demand supply gap and hinder industry profitability.

Aluminum alloys from additive manufacturing with metal powders market demand should witness gains over 27% upto 2024. Components manufactured from aluminum powder have usage in automotive, motor racing and general engineering as it is light and rigid.

UK additive manufacturing with metal powders market demand should witness growth at over 25% during the forecast timeline. Laser Engineering Net Shape (LENS) and Electron Beam Melting (EBM) technique is widely used in making of complex geometrical structures for automotive and aerospace sectors. Increased production and sales of motor vehicles along with demand of lightweight vehicles in the region should favor industry growth.

GE, 3D Systems, EOS, Pratt & Whitney, Optomec, Renishaw, Arcam, ExOne and Trumpf are the some of the industry participants in additive manufacturing with metal powders market. Manufacturers are engaging in partnerships and collaborations to strengthen their global presence along with increased investments in AM equipment and research to further develop the technology may drive metal 3D printing market demand.

Additive Manufacturing with Metal Powders Market Size By Manufacturing Technique (Powder Bed {Direct Metal Laser Sintering, Selective Laser Melting, Electron Beam Melting}, Blown Powder {Direct Metal Deposition, Laser Engineering Net Shape}), By Material (Alloy {Titanium, Cobalt, Copper, Nickel, Aluminum}, Stainless Steel {Austenitic Steel, Martensitic Steel, Duplex Steel, Ferritic Steel}, Other Steel {High Speed Steel, Tool Steel, Low Alloy Steel}, Precious Metal), By Application (Aerospace, Automotive, Medical, Oil & Gas), Industry Analysis Report, Regional Outlook (U.S., Canada, Germany, UK, France, Italy, Spain, Russia, Poland, China, Japan, India, South Korea, Australia, Taiwan, Brazil, Mexico, Argentina, Saudi Arabia, UAE, South Africa), Application Development Potential, Price Trend, Competitive Market Share & Forecast, 2017 – 2024”.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product