Supply Chain Success in Idaho

As the pandemic was getting underway, our CEO, Bob White, decided to invest heavily in raw materials. Bob wanted to ensure EPC customers did not get caught in a bad, deprived situation.

Unleashing the Potential of Generative AI for Unprecedented Success in the Manufacturing Industry

By leveraging Generative AI, manufacturers can initiate a wide array of use cases in areas such as customer service, product and quality control, supply chain, logistics, predictive maintenance, marketing and sales, finance, compliance and legal, and research and development

Spotlight on Fronius Welding Automation - Perfect Symbiosis of Welding Technology and Kinematics

Welding engineers all over the world associate the name Fronius with innovative welding technology. Above all, the innovators are known for providing high-performance, high-tech welding systems.

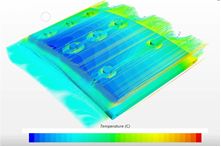

AI and AM: A Powerful Synergy

Artificial intelligence applied to designs of additively manufactured products goes beyond standard optimization to produce dramatic quality and performance gains in much less time

NVIDIA and Hexagon Deliver Suite of Solutions for Accelerating Industrial Digitalization

Sweden's Hexagon AB is connecting its reality capture and manufacturing platforms to NVIDIA Omniverse so enterprises can more easily develop and deploy digital twin applications.

Process and System Efficiency: You Can't Improve What You Don't Measure

KPIs are quantifiable metrics used to measure the success of a particular process or system. They are typically tied to specific objectives and goals and are used to track progress over time.

CAPTURE 3D Enables Fast Digitalization of Extra-Large Objects with the ZEISS ATOS LRX

CAPTURE 3D makes the fast digitalization of very large parts possible with the ZEISS ATOS LRX accurate 3D scanner engineered for fields such as heavy casting, shipbuilding, aerospace structures, automotive and wind energy.

Robotic Chef 'Beastro™' takes Orders, Cooks-and Cleans up--controlled by Unitronics

The Kitchen Robotics company Cloud receives the customer orders via website or app, and sends the appropriate commands to the UniStream PLC, using an API that implements a dedicated TCP/IP protocol written in UniLogic, Unitronics all-in-one development software.

AM Post-processing: Benchmarking Alternative Technologies

With a variety of post-processing technologies available, it is essential to understand their capabilities and limitations. In this article, we will benchmark different post-processing technologies and explain why mass finishing technologies are the best fit and the most efficient solution.

Choosing a Robotic Spindle for Deburring

The nature of the deburring task is highly repetitive, dirty, and carries a risk of injury. Retaining personnel for such a strenuous and messy job is challenging. Robotic deburring is an appealing option for these reasons, plus the results are more precise and repeatable.

Business Case for Artificial Intelligence in the Plastic Injection Molding Business

A leading plastic injection molding factory was experiencing unusually high defect rates in a specialty plastic bottle designed for the healthcare industry. They were unable to identify or determine the root causes associated with these unusually high defect rates.

Benefits of Gearbox Customisation for OEMs

A customised gearbox not only increases the life-span of existing hardware, but it can be designed to evolve and develop alongside the needs and goals of the business.

Successful Conversion of a Vehicle Assembly With Electric Monorail System

The challenges that arose during the course of the project and how they were overcome are reported by the departments involved. The end result was a system with brilliant production performance.

Induction Seal vs Heat Seal: What's the difference?

The main difference between an induction seal and a heat seal is the way in which the seal is created. Induction sealing uses electromagnetic induction to generate heat and create a tamper-evident seal, while heat sealing uses heat to bond two materials together.

How Manufacturers Can Keep Up With the Growing Demand for EVs

It takes significant forethought and effort to secure the resources for operating a plant that only handles EV production. However, it could help EV makers get ahead of competitors and tackle some of their delays.

Records 1 to 15 of 554

Featured Product

PI USA - Hexapod for Industrial Alignment

This new compact 6-axis hexapod was designed with 24/7 industrial precision alignment tasks and easy serviceability in mind. It is equipped with absolute encoders (no need for referencing) and motor brakes that automatically engage during a loss of power, for extra safety. Debuting at Photonics West 2025 last month, applications include camera lens alignment, micro assembly, and fiber optical alignment applications.

.jpg)