Automating Equipment Maintenance Essential for Fire Safety in Facilities

Exploring Manifold Design

Reaping Good Harvest: Artec Leo Offers Innovation to Improve Harvesting in France

RealWear Launches World's First Hands-Free, Voice-Controlled Thermal Camera

Most Accurate Lotus Car Ever, Thanks to Cutting Edge Metrology

American Welding Society Announces FABTECH 2022 Panel Discussions, Podcasts, Professional Program, Welding Track and Product Discounts

The Way to Combine Metal and Plastic: Insert Molding

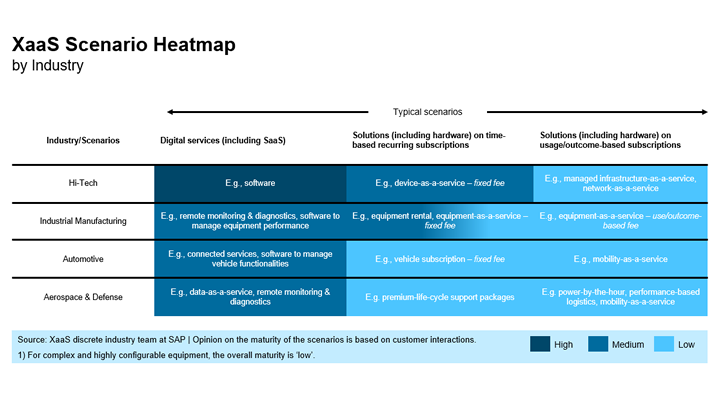

Has XaaS Lived up to the Hype?

Walter Pyramid - Galvanized Fabricated Tube Steel and Pipe Structures

Optimizing Load Carrier Utilization in Production and Intralogistics

Reasons Manufacturers Should Use CAD Automation

How To Choose A Suitable Electric Motor For Your Application

Scaling Operational Excellence in the Oil and Gas Industry

The Critical Role of Metrology in Product Development - a Case Study

How VR and AR are Creating the Next Generation of Welders

Records 16 to 30 of 554

First | Previous | Next | Last

Featured Product

.jpg)

.jpg)