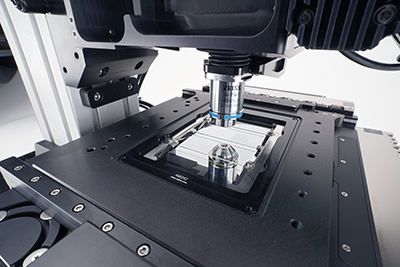

Case Study: Affordable Dual-View Microscope System

Zaber's Nucleus® microscopy modules share a common control protocol mounting features, and optical and electrical interfaces, enabling them to be combined in ways that are simply not possible with other microscopes.

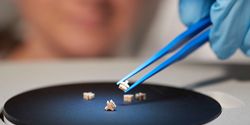

Validation & Quality Control: Optimizing Micro Molding Outcomes

But there is one aspect of a micro molding project that is often overlooked, especially when customers are assessing the in-house capabilities of a micro molding partner, and that is validation and quality control.

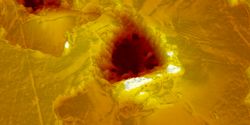

The Critical Role of Metrology in Product Development - a Case Study

During the development process, Metronom recognized the critical role of metrology in both R&D and production quality control for its CGM. When working at a scale that is difficult to image with traditional microscopes.

Additive Manufacturing - New Frontiers for Production & Validation

AM has enabled concurrent engineering"•where all relevant departments can be engaged early in the product development process. Concurrent engineering replaces traditional "over-the-wall" product development, where design iterations could be delayed by weeks.

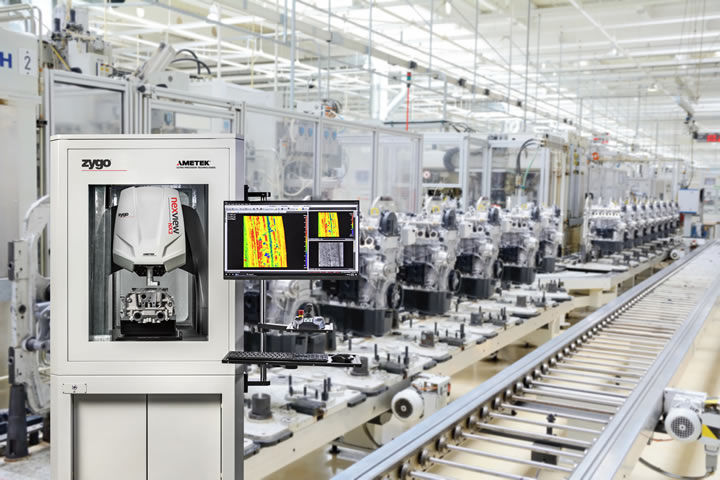

METROLOGY & INDUSTRY 4.0

Today's most sophisticated metrology systems drive quality assurance (QA) which has become a fundamental digital task which in and of itself facilitates efficient and cost-effective production processes.

METROLOGY FOR MICRO MOLDING - A CASE STUDY

Eric Felkel, Product Manager, ZYGO Corporation

3D Optical Metrology - Versatile Tools for Today's Advanced Manufacturing

When looking at metrology, general discussion often revolves around the relative merits of contact or non-contact measurement solutions. There is now a drive across nearly all industries for smaller and more complex components.

Automotive Control System Manufacturer Invests in Mulit-sensor Inspection

To upgrade the inspection capabilities of its measurement laboratory, the quality department at the Chassis & Safety division of automotive equipment manufacturer Continental invested in two LK Metrology ALTERA multi=-sensor coordinate measuring machines (CMMs).

Records 1 to 8 of 8

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

The FLIR Si1-LD is an easy-to-use acoustic imaging camera for locating and quantifying pressurized leaks in compressed air systems. This lightweight, one-handed camera is designed to help maintenance, manufacturing, and engineering professionals identify air leaks faster than with traditional methods. Built with a carefully constructed array of MEMS microphones for high sensitivity, the Si1-LD produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments. The acoustic image is overlaid in real time on a digital image, allowing you to accurately pinpoint the source of the sound, with onboard analytics which quantify the losses being incurred. The Si1-LD features a plugin that enables you to import acoustic images to FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation. Field analysis and reporting can also be done using the FLIR Acoustic Camera Viewer cloud service. Transferring of images can be managed via memory stick or USB data cable. Through a regular maintenance routine, the FLIR Si1-LD can help facilities reduce their environmental impact and save money on utility bills.

Manufacturing and Automation - Featured Company

OnLogic

OnLogic is a global industrial computer manufacturer who designs highly-configurable, solution-focused computers engineered for reliability at the IoT edge. Their systems operate in the world's harshest environments, empowering customers to solve their most complex computing challenges, no matter their industry. OnLogic has helped more than 70,000 customers worldwide advance their ideas with computers that are designed to last, built to order and delivered in days.