Zaber's Nucleus® microscopy modules share a common control protocol mounting features, and optical and electrical interfaces, enabling them to be combined in ways that are simply not possible with other microscopes.

Case Study: Affordable Dual-View Microscope System

Case Study: Affordable Dual-View Microscope System

Case Study from | Zaber

Introduction: Dual-View Microscopy Challenge

A customer recently approached Zaber with an interesting imaging challenge. They needed a microscope system which could simultaneously image a sample from the top and the bottom. In their ideal system, a camera would be mounted to the upper optical path, while the lower optical path would be coupled to a spectrometer. This configuration would enable a user to view a wide area of the sample with a low magnification objective from the top, while simultaneously making spectrographic measurements on a small area of interest using a high magnification objective from the bottom. Each objective would require independent focus control. Most importantly, the upper and lower optical axes would need to be precisely aligned to ensure concentricity. This would ensure the spectrographic measurements were made from the exact center of the field of view in the camera.

Solution: A Modular Approach

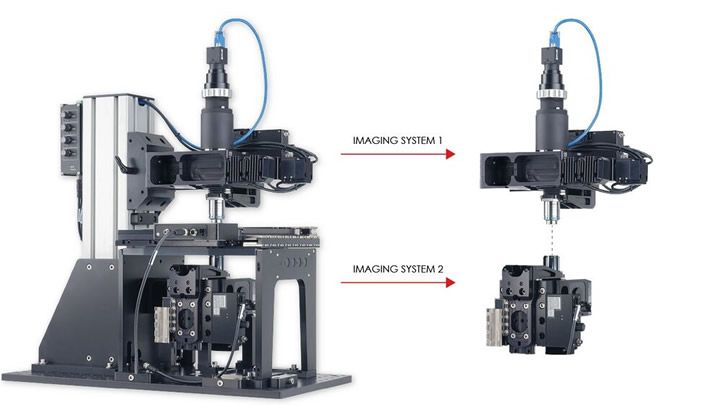

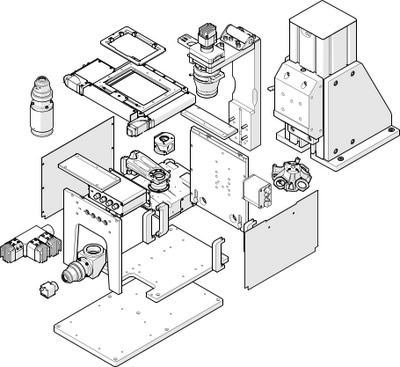

Zaber’s solution shows how the modularity of our Nucleus® microscopy platform can be used to solve difficult problems that would be impossible for other providers to address affordably. We drew from our wide range of Nucleus microscope modules, combining our upright and inverted microscopes into a single system.

Zaber’s Nucleus® microscopy modules share a common control protocol mounting features, and optical and electrical interfaces, enabling them to be combined in ways that are simply not possible with other microscopes.

Figure 1. Nucleus interchangeable microscope modules can be combined as required.

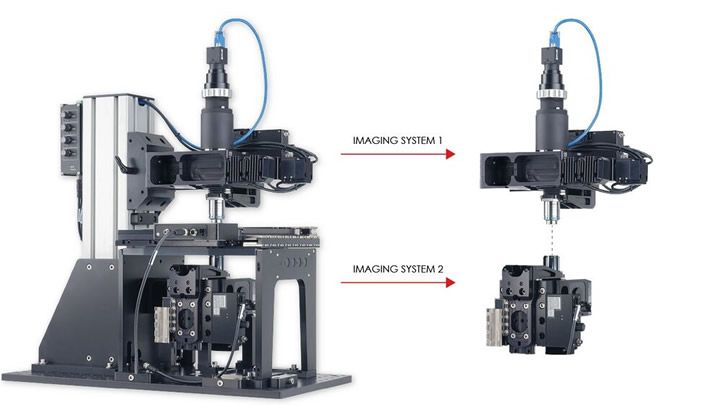

For this dual system, each microscope core includes:

- mounting for emission

- excitation and dichroic filters

- a high speed, high repeatability focus stage

- a tube lens and camera mount assembly

A three channel LED epi-illuminator was mounted to the upper optical path.

While standard Nucleus microscope systems would typically include automated filter and objective switching, these modules were not needed for this application. Instead, we used our OEM single objective and single filter microscope cores. This reduced the cost of the system by 25% without reducing the imaging or spectrometer performance!

With the benefit of using almost all off-the-shelf standard products, the remarkably low cost of this system was $44,000.

Implementation: Optical Alignment and System Integration Process

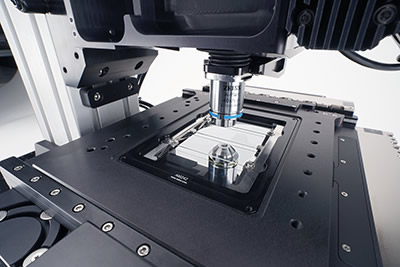

To simplify assembly at the customer site, Zaber explored two options for easy and accurate co-registration of the upper and lower optical systems (Fig. 2). The first approach was to achieve a coarse alignment using a precision rod that slid in through the upper camera port and out through the lower camera port. Following this we installed an illuminator in one microscope core and a camera in the other. It was then possible to use the optical feedback of the focused point of light as seen through the camera to fine tune the alignment of the systems using set-screws on the base plate of the lower system. To assist in the alignment, Zaber loaned the customer an extra tube lens and camera mount assembly. This part is not needed when the spectrometer is connected, but having it made the alignment procedure much easier.

Figure 2. Two precisely co-registered objectives ensure the spectrometer path and the imaging path are centered.

Conclusion

The ability to achieve such precise, dual-view functionality at a remarkably low cost of $44,000 speaks to the efficiency and affordability of Zaber’s modular approach. By strategically selecting components and optimizing the alignment process, our Custom Engineering team delivered a system that met the customer’s demanding specifications at a surprisingly affordable price. This case study demonstrates how Zaber's Nucleus® microscopy platform offers a cost-effective pathway to advanced imaging and spectroscopy solutions, even when requiring highly specialized configurations.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product