As the pandemic was getting underway, our CEO, Bob White, decided to invest heavily in raw materials. Bob wanted to ensure EPC customers did not get caught in a bad, deprived situation.

Supply Chain Success in Idaho

Supply Chain Success in Idaho

Case Study from | Encoder

In a time marked by global supply chain disruptions, many industries encountered challenges in maintaining a steady flow of products. However, amidst this turmoil, Idaho-based Encoder Products Company emerged as an example of resilience, showcasing an exceptional ability to ensure uninterrupted operations and a consistent supply of motion feedback devices (encoders) to keep our customers producing. So, what set us apart during this turbulent period?

Strategic Foresight

As the pandemic was getting underway, our CEO, Bob White, decided to invest heavily in raw materials. Bob wanted to ensure EPC customers did not get caught in a bad, deprived situation. Because EPC is not leveraged financially, we were able to use our retained earnings and positive cash position as a competitive advantage. Bob and CFO, Mark Halliday, immediately started working on getting large quantities of aluminum, wire, steel, bearings, and electronic components on order in massive quantities.

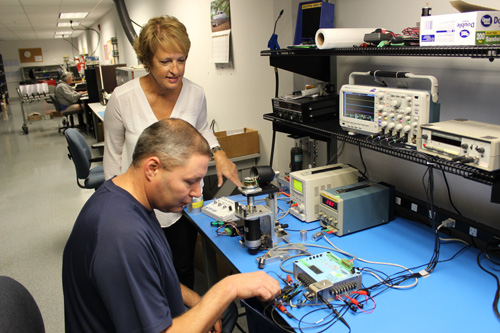

Vertical Integration Means Agile Adaptation

Since EPC is vertically integrated, we were able to store the materials onsite for production without having to pay extra for storage. The cost of shipping increased over time, but in the beginning, the rates were standard and not yet inflated. Bob and Mark were able to set the company up for future success as the rest of the world was struggling with global supply chain and delivery issues. All our manufacturing – CNC metal work, SMT board stuffing, stripping wires and making cable, pinning connectors, soldering pins, testing, quality control, custom configurations, and special engineering requests –are all accomplished in-house. A few branded items were delayed but everything else we manufacture in Idaho and were able to ship on time to beat out the competition.

Robust Communication

Once the supply chain issue started hitting our competitors hard, customers noticed we did not have the same delivery issues and started rewarding us with new business opportunities. We were crossing over all the major players to our U.S.A. made encoders. Once customers started using our products, working with our tech support, and engineering team members, they wondered why they were not using us before. They made comments to us along the way like, “Why haven’t we used you before now?” and “How can you deliver when everyone else is having so much trouble?” also “Your engineering team is so quick to respond and so efficient! We really love working with EPC!”

Eventually, the initial raw materials purchase depleted, and as EPC realized continued supply chain pressure, we began re-engineering for sustainability. There were many components that were in short supply or discontinued. Microprocessors, certain detector chips and LEDs, and many very specifically designed circuits had to be redesigned. EPC invested heavily in new engineers to hunt down alternatives and speed through the approval process for our encoder designs. Customers were made aware of our issues, and we made every effort to keep them informed of our progress. Many customers were more than happy to help us beta test the new designs to receive the first units off the line when we were ready to ship. Everyone seemed to be eager to pitch in on the effort to find a solution as soon as humanly possible. These customers were very pleased that EPC was forward thinking in their approach to solving this supply chain disruption.

Customer-Centric Approach

Some of the lessons we learned from this global event will stick with us for many years to come. Some of the casualties over these past few years are unfortunate and painful. Testing one’s mettle is not something you often look forward to. Looking back can oftentimes be painful as well. The journey was bitter-sweet to say the least. We lost our founder and his wife in 2020. His legacy lives on in the culture of EPC and his steadfast work ethic continues to inspire many of our employees to this day. We also were able to put many of our current customer service, engineering, and manufacturing policies in place due to the challenges of the past few years. This lesson has cost us a lot, but it has also enriched us in many ways. Customers have rewarded us with new business, loyalty, and a high level of respect. We are in business relationships which are mutually beneficial with distributor partners, end users, and direct OEM customers that we had not previously enjoyed.

Harnessing Technology

Additionally, during these few years of global supply chain difficulties, we managed to continue new product development on our latest absolute encoder. The A36R idea was initialized just prior to 2020 and we finished the design this past summer. This encoder boasts 22-bit single-turn and 24-bit multi-turn resolution, reflective LED technology, with BiSS-C and SSI communication protocol. The reflective photoelectric technology allows us to make a very small, thru-bore encoder for many different customer requirements and applications. EPC being able to continue development and innovation during these adverse global conditions is somewhat astounding. We are blessed beyond belief and grateful beyond measure for our successes and accomplishments.

The momentum we received from the simple, yet somewhat risky, decision to purchase raw material in masse was tremendous. And the success of this move was amazing. We continue to enjoy great success due to our early decision to get ahead of the pandemic supply chain constraints. Many customers continue to reward us with new business opportunities and often ask us to develop new encoders around their new designs. We are grateful we made some good decisions early on, and we are thankful that we never gave up. Our leadership team and owners were willing to risk a great deal of revenue and profitability to ensure our customers were taken care of during this very difficult time in our world.

Looking Ahead

EPC is in the middle of restructuring our external strategic team and preparing for the next wave of success. We have hired new team members who bring with them experiences from all of our major markets; Printing/Marking/Coding, Packaging, Material Handling, Labeling, Motor and Drives, Automatic Guided Vehicles, Agri-tech, and Conveyors, just to name a few. Our Sales, Marketing, and Business Development plans are in place and being executed to plan. We are poised to win big from the foundation in place due to the challenges and change born out of this very strange time we’ve all just lived through.

In a landscape where supply chain disruptions became the norm, EPC not only survived but thrived, reinforcing our reputation as a dependable partner for high-quality encoder products. Our success story during these challenging times serves as a testament to strategic planning, adaptability, and unwavering dedication to excellence.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Encoder Products Company

At Encoder Products Company, we specialize in the encoders that provide you with motion feedback. EPC has been a leading designer and manufacturer of motion sensing devices for more than 50 years, we understand that each industrial automation application is different, and you need encoders that fit the needs of your applications. Our encoders are highly configurable, offer an array of shaft or bore sizes, output types, connector types, mounting options, and resolutions as high as 65,536 CPR.

Other Articles

Motion feedback really is everywhere – Here's how encoders help make beer

Considerations for Choosing the Right Encoder for Your Application

SCARA Robot Sorts Recyclables Using a Simple Conveyor Speed Feedback System

More about Encoder Products Company

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product