Key Considerations for Maximizing Manufacturing Efficiency

It's true that advanced simulation tools have helped improve the efficiency and effectiveness of robotic workcell design and path planning, but it still remains an incredibly time consuming process.

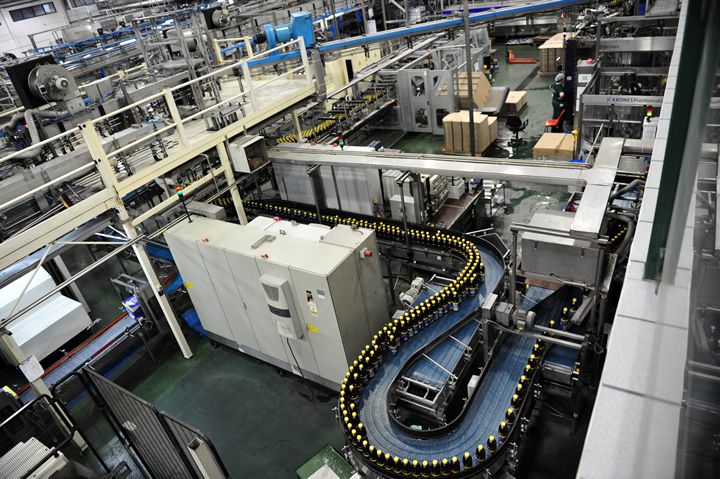

Maximizing Operation Efficiency through Manufacturing Processes

Cross-functional collaboration isn't just helpful, it's the backbone of a smooth new product introduction. You can have the best design on paper, but if engineering, operations and supply chain aren't aligned from day one, you're setting yourself up for late-stage surprises.

DFAM: WHY PURPOSEFUL GEOMETRY MUST REPLACE PASSIVE OPTIMISATION

Rather than embracing the full potential of AM, many engineers merely adapt existing designs or lean heavily on software-driven outputs, confusing automation with optimisation.

From Displacement to Empowerment: How Robotics Developers Can Lead the Workforce Reskilling Revolution

As automation continues to integrate into our factories, warehouses, and supply chains, the conversation around workforce transition and reskilling has become one of the most urgent and defining challenges of our time.

Securing Intellectual Property in 3D Printing: A New Era of Protection

By decentralizing manufacturing and leveraging external service bureaus, companies can deliver products faster and tailor offerings. However, due to both its quick, cost-effective, and precise manufacturing process, 3D printing is a fine target for counterfeiting.

FMEAS - Reducing the risk of failure

For anything complex, the best method is to start back when you design the product by carrying out a review called a Failure Mode and Effects Analysis, universally abbreviated FMEA.

ENGINEERING THE AMERICAN DREAM

Building the American Dream: Marcus Schneck, CEO at norelem explains how the company's US expansion will support American design engineers in creating exciting new products.

Preparation - Is a Key. How to Address Challenges of IoT Development at Discovery

Despite the redoubled efforts made to fix issues, more than half of the IoT projects are considered unsuccessful by their initiators. For some reason, companies often prefer to ignore this fact.

State of Reliability and Hardware Design

Every industry we serve-from high-performance computing and consumer devices to automotive, electrification and connected healthcare-is impacted greatly by user experience

Reverse Engineering for a Model-Based World

The list of reverse engineering applications is long and will continue to grow as engineers create new and creative ways to use the technology.

Looking to the Future: Visual Commerce in Manufacturing

The reality is B2B buyers increasingly expect interactive and engaging commerce offerings. It's time for manufacturers to up their digital commerce game to keep B2B customers coming back.

New Ideas, Collaboration Help Brenton Drive Four Major Product Handling Upgrades to KW Container

This cell included four robots picking lids and packing them into one of four SKUs. This cell, encapsulated in a small footprint, also included an auto adjustable case sealer to accommodate the four different SKU boxes, a palletizer and stretch wrapper.

Exploring Manifold Design

Manifolds are complex parts that require several levels of expertise to optimize. At Inkbit, we are optimizing the manufacturing of manifolds that finally unlock the geometric freedom of additive manufacturing.

How to Approach Make Vs. Buy Decisions for Optic Assembly

Before making a decision, it's important to analyze whether making or buying optical parts and components is the best approach for your team, budget, and business goals.

Overcome Automation Challenges to Create a Better Smart Factory

Manufacturers must know what challenges they face and how to overcome them to make the most of these investments. Here are the most common automation challenges and how to address them.

Records 1 to 15 of 25

Featured Product

MOTION CONTROLLERS FOR MINIATURE DRIVES AND MICRODRIVES

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new Motion Controller is ideal for integration in equipment manufacturing and medical technology applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to approx. 100 W and is suitable for DC-motors with encoder, brushless drives or linear motors.

Manufacturing and Automation - Featured Company

MRPeasy

MRPeasy is a seriously powerful and easy to use ERP software for small manufacturers that gives you everything you need to manage your manufacturing and distribution processes. Integrating sales, procurement, inventory, production, finances, and your team, it provides you with an accurate real-time overview of your operations.

MRPeasy is trusted by 2000+ small manufacturers worldwide, 700+ of which are based in the US and Canada. Our users report a 54% average improvement in the overall performance of their business and a 42% increase in on-time deliveries.

Try for free, no credit card needed.

.jpg)

.jpg)