Desktop Metal Remains Focused on Path to Profitability After Preliminary Tally Shows Stratasys Shareholders Did Not Approve the Merger Agreement

Why Visual AI Inspection Is Essential for Detecting PCB Defects

The Sky's the Limit: Additive Manufacturing in Aerospace Will Soar with Parts Certification

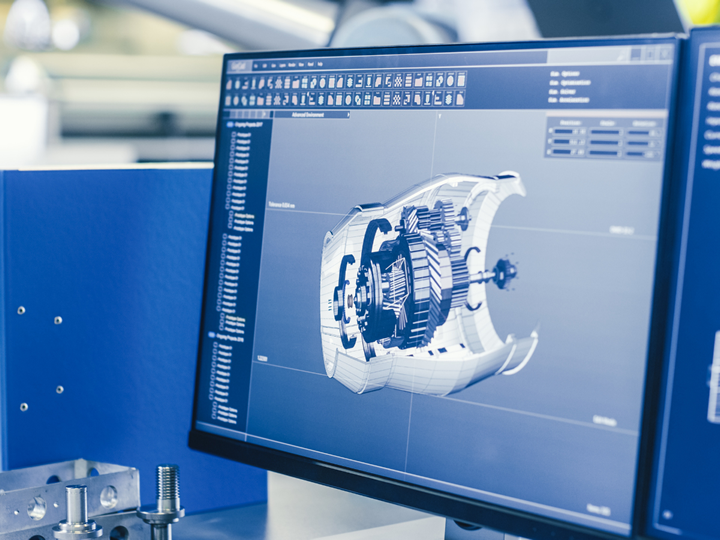

AI and AM: A Powerful Synergy

What Are the Benefits of Adding IoT to Laser Cutting?

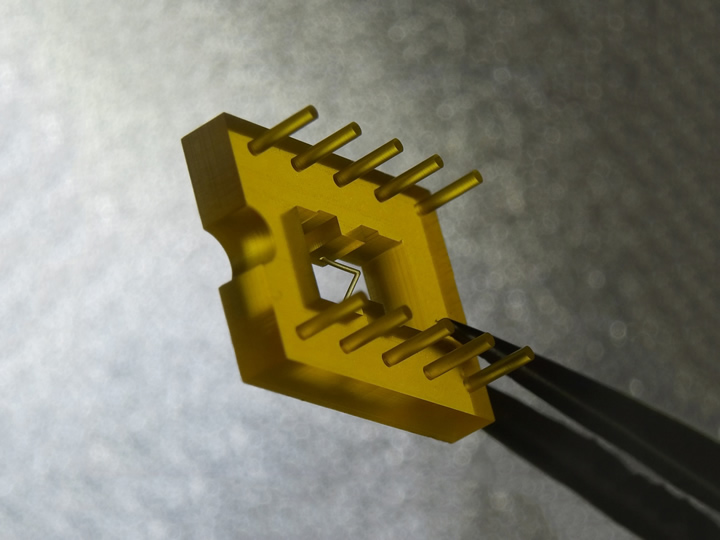

PHOTO CHEMICAL ETCHING: REVOLUTIONIZING ELECTRIC VEHICLE COMPONENT PRODUCTION FOR CLIMATE CHANGE MITIGATION

How 3D Printing Can Dramatically Reduce Carbon Emissions in the Manufacturing Industry

How the Additive Manufacturing Industry Emphasized End-Use Part Production at Rapid + TCT 2023

Unlocking the Value Potential of Additive Manufacturing

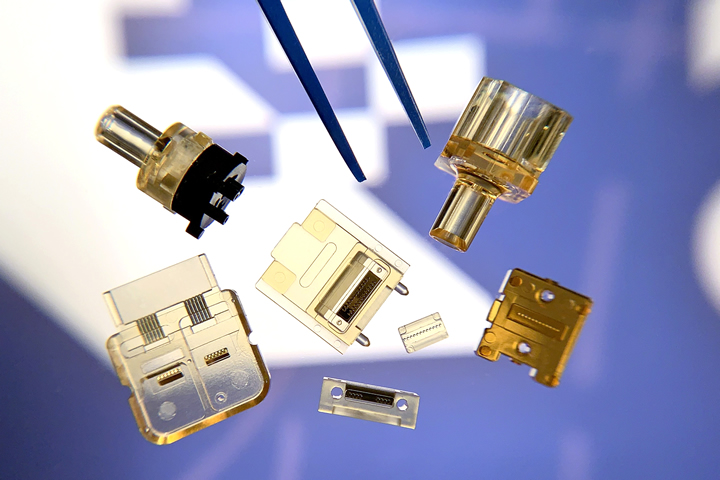

MICRO MOLDING - PLACE THE FOCUS ON OUTCOMES

Weerg achieves cycle time reductions of over 50% with post processing technologies from AM Solutions

Proving Out Metal AM for Distributed Manufacturing on a Global Scale

Sustainability and Plastic Injection Molding in the Automotive Industry

QUALITY AND VALIDATION IN 3D PRINTING

HORIZON LAUNCHES BREAKTHROUGH TECHNOLOGY AT FORMNEXT 2022

Records 31 to 45 of 449

First | Previous | Next | Last

Additive & 3D Printing - Featured Product

.jpg)

.jpg)

.jpg)

.jpg)