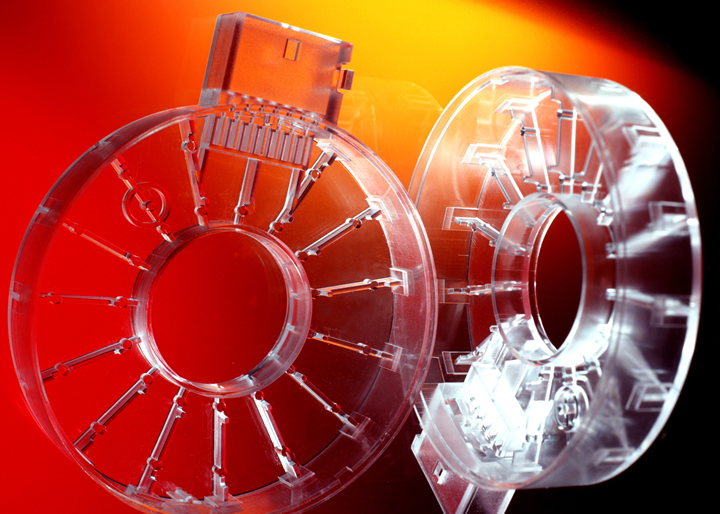

THE ROLE OF MICRO MOLDING IN THE PRODUCTION OF MICRO-OPTICS

Achieving the exacting tolerances required for these delicate micro-optic parts necessitates a deep and specialized processing knowledge that is distinctly different from that used for typical mechanical parts.

THE IMPACT OF 3D PRINTING ON MICRO MOLDING - A SYNERGISTIC APPROACH

The precision achieved in micro molding is not just about miniaturization, it's about reproducing complex shapes with exacting tolerances that are measured in microns repeatably.

NANO DIMENSION'S TERA 250vx ENHANCES ACCUMOLD'S MICRO INJECTION MOLDING SERVICE

Today, Micro-Additive Manufacturing (Micro-AM) solution like the Tera 250vx from Nano Dimension can additively manufacture or 3D print micro parts and components only previously possible through the use of micro injection molding.

The Critical Role of Risk Mitigation & Vertical Integration in Successful Micro Molding

Alex Anderson, Sales Engineer at Accumold systematically explores the crucial implications of vertical integration in micro molding projects.

The Challenges of Boomerang Projects in Micro Molding: a Customer Perspective

In the world of micro molding, where precision and efficiency are paramount, the concept of boomerang projects can present significant challenges for both customers and micro molders.

OPTIMIZING OUTCOMES THROUGH MICRO MOLDING - AN EXPERT PERSPECTIVE

In this Q&A interview, Craig Tappe, Sales Engineer at Accumold discusses various aspects of the micro molding process, and discusses why it is important to ensure that when short-listing your preferred suppliers, the correct questions are asked.

MICRO MOLDING - PLACE THE FOCUS ON OUTCOMES

You need to understand what micro molding can do in terms of stimulation of innovation, what it can deliver in terms of manufacturing efficiency, and what - above all - it can do to achieve increased functionality in parts that are often required to be smaller and smaller

How Micro AM is Impacting Time-to-market for Precision Plastic Parts

When using micro AM, by week 7 a design can have been refined numerous times as the process requires no traditional tooling, just DRST. This means that time and focus in this early stage of product development can be spent on design optimization.

Tolerance Attainment in Micro Molding

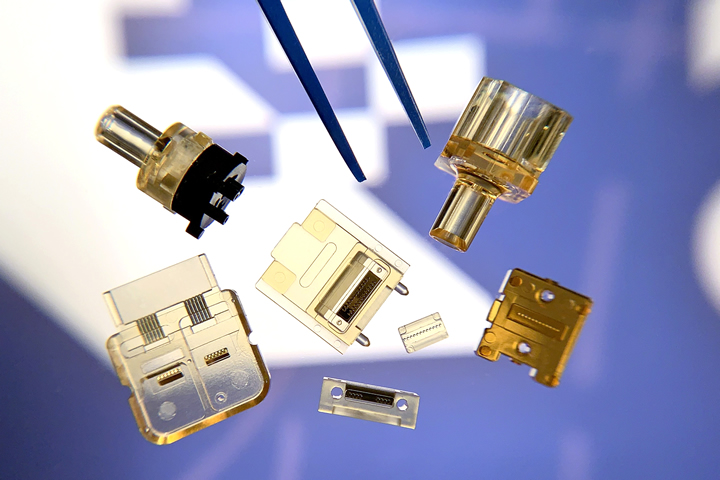

When manufacturing micro parts and components, it takes a coordinated team of experts in design, materials, tooling, molding, validation, and automated assembly to successfully manufacture customer parts at high volume.

Micro Molding - Material Selection and Design Concerns

You need to understand the basic design approach and really bottom out what you can and cannot do, as when micro molding, even the smallest design change can be catastrophic and completely derail a project.

The Critical Role of Validation in Micro Molding

Measurement should be a central consideration in every quote issued by a micro molder. If a micro molder can make the steel micro tool, and subsequently mold the part, sure as night follows day it will need to be measured.

MICRO MOLDING - THE TOOLROOM PERSPECTIVE & DfMM

DfMM has a massive impact on the tool build; this will therefore have a disproportionate effect on product development time, cost, and indeed the quality of final product.

Micro Molding & Microfluidics - Overcoming Complexity Issues

Microfluidics is an extremely dynamic niche today, and will continue for many years to cement the importance of micro molding as a technology used to drive innovation in the medical sector in such applications as drug delivery devices, implants, and diagnostics

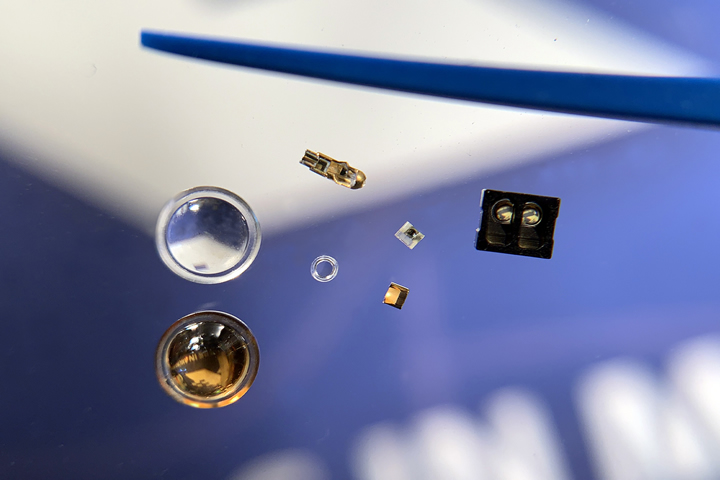

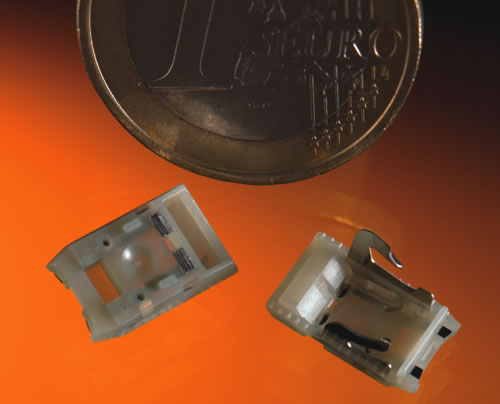

MICRO MOLDING FOR MICRO-ELECTRONICS

Perhaps like no other, the field of microelectronics exemplifies the drive towards miniaturization, the obvious reduction in size of everyday household appliances and cell phones showing the extent to which products containing electronic components have been reduced in size.

Records 1 to 14 of 14

Featured Product

Cold air to -50°F (-46°C) from your compressed air supply - with no moving parts!

A low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. Using an ordinary supply of compressed air as a power source, vortex tubes create two streams of air, one hot and one cold, with no moving parts.

Vortex tubes can produce:

"¢ Temperatures from -50° to +260°F (-46° to +127°C)

"¢ Flow rates from 1 to 150 SCFM (28 to 4248 SLPM)

"¢ Refrigeration up to 10,200 Btu/hr. (2571 Kcal/hr.)

Temperatures, flows and refrigeration are adjustable over a wide range using the control valve on the hot end exhaust.

EXAIR Vortex Tubes are constructed of stainless steel. The wear resistance of stainless steel, as well as its resistance to corrosion and oxidation, assures that EXAIR Vortex Tubes will provide years of reliable, maintenance-free operation. https://exair.co/184_530

Manufacturing and Automation - Featured Company

Parvalux Electric Motors Ltd

Parvalux is a leading global manufacturer of geared motor solutions with over 70 years' experience in creating the perfect combination of motor and gearbox to match the customer's application. Whilst we offer thousands of standard options we can easily customize any motor or gearbox to meet your exact requirements at no or minimal extra cost. Our design team can work closely with your own to optimize your solution for your application helping you to secure a genuine competitive advantage in your market. Our products are found in hundreds of applications but we are particularly strong in healthcare, leisure, mobility, transport, and a diverse range of industrial applications.