DFAM: WHY PURPOSEFUL GEOMETRY MUST REPLACE PASSIVE OPTIMISATION

Rather than embracing the full potential of AM, many engineers merely adapt existing designs or lean heavily on software-driven outputs, confusing automation with optimisation.

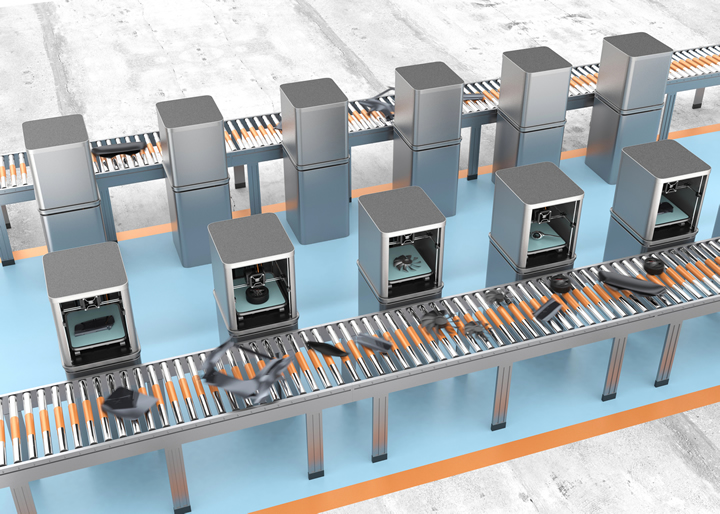

Barriers to investing in CNC automation in 2025 - Transforming CNC automation obstacles into pathways for growth

Here Hakan Aydogdu, CEO at Tezmaksan Robot Technologies delves into these critical obstacles and reveals how innovative technologies and forward-thinking strategies are breaking down barriers, paving the way for a transformative shift in manufacturing.

3D Printing Revolution: How Localized Manufacturing Is Reshaping Global Trade

In the realm of advanced manufacturing, robotic large-format additive manufacturing (LFAM) is rapidly emerging as a strategic tool for businesses seeking to bypass traditional trade constraints and build more resilient operations.

Renishaw helps Tronosjet Manufacturing achieve FAA certification

Renishaw supplied multiple laser powder bed fusion (LPBF) AM systems, which Tronosjet uses to produce various aircraft components.

Securing Intellectual Property in 3D Printing: A New Era of Protection

By decentralizing manufacturing and leveraging external service bureaus, companies can deliver products faster and tailor offerings. However, due to both its quick, cost-effective, and precise manufacturing process, 3D printing is a fine target for counterfeiting.

The Evolution of Mass Custom Manufacturing: Why the Industry Needs a High-Velocity Shift

HVMC is not just faster production but a fundamental reimagining of how custom manufacturing operates. By standardizing and automating processes without sacrificing the ability to tailor products to specific needs, HVMC has the potential to transform the landscape.

The Hidden Cost of Convenience - Why 3D Printing Shouldn't be Left only to an Algorithm

At first glance, the idea of an entirely self-service 3D printing experience is appealing. Who wouldn't want an instant quote? Who wouldn't prefer the simplicity of a few clicks over a back-and-forth exchange with a human?

WHY PHOTO-CHEMICAL ETCHING IS BECOMING CRITICAL FOR HIGH-PRECISION INDUSTRIES

As industries continue to innovate, the demand for high-precision components grows exponentially. Medical devices require intricate surgical instruments and implants that must meet stringent safety standards.

AI-Powered Additive Manufacturing Transform Production and Supply Chain

This potent merger of AI and AM fosters innovation by simplifying workflows and allowing for extraordinary design opportunities at lower costs. It signifies a new production age where advanced technology transforms efficiency and innovation.

FUTURE-PROOFING MANUFACTURING WITH PHOTO CHEMICAL ETCHING

Photo-chemical etching (PCE) is proving to be more than just a manufacturing process, and instead is seen as an enabler of innovation and a vital tool for future-proofing.

Raising the Bar for Additive Manufacturing with Expert Service & Delivery - Beyond the Status Quo

Utilising industrial 3D printing for any manufacturing discipline, whether for rapid prototyping, tooling, or, increasingly, production on demand, does not come without its own set of challenges, but deploying AM can also bring great advantages.

Top Manufacturing Trends Looking Into 2025

The manufacturing industry thrives on competition. If you can keep up with the digital transformation, emerging technology, and workforce changes, you can leverage opportunities to boost operational efficiency and put competitors in your rearview mirror.

Equal Parts: Assessing the Viability of Large Format Additive Manufacturing

Whether you're a manufacturer already embracing the technology or still assessing what it could do, there a few things to consider when it comes to evaluating the suitability of the technology for specific parts production and which parts could be optimized with LFAM.

Using Advanced Cooling Techniques to Reduce Cycle Times and Improve Quality in Injection Molding

If parts do not cool down enough or cooling happens unevenly, they can shrink or warp, requiring time-consuming rework processes. Fortunately, numerous ways exist to accelerate cooling time while ensuring it happens effectively.

3D Printing and Sustainable Auto Manufacturing: A Glimpse into the Future

The excitement around 3D printing in the automotive industry is easier to understand in light of growing sustainability needs. While vehicles themselves may be the most obvious target for emissions reductions in this sector, the production side needs improvement, too.

Records 1 to 15 of 449

Additive & 3D Printing - Featured Product

BigRep ONE: Large-Scale 3D Printing

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 350 systems installed worldwide, it's a trusted solution for prototyping and production by designers, innovators, and manufacturers alike. Featuring a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)