A Quick Guide to Workplace Audits and Inspections

Performance Solutions by Milliken - Safety Bootcamp

What OSHA's Revised Lead Standards Could Mean for Workers

Sanitation Challenges Modern Manufacturers Face (and How to Fix Them)

4 Easy Steps to Successful Incident Management

4 Steps to Take Now Toward Achieving CMMC Compliance

4 of the Most Important Safety Practices in Automated Factories

2022 Online Training Trends: What to Expect in Safety and Beyond

6 Emerging Solutions for Industrial Noise Control

Now is the time for Manufacturers to Invest in Safety and Compliance

Solutions for the Highest Hygiene Requirements

SafetyCulture Summit 2021: Made Extraordinary

Dialing Up Productivity with Workstream Collaboration

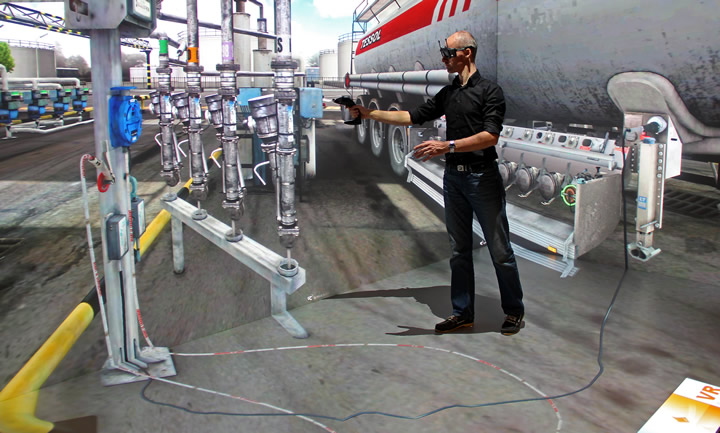

How VR can Ensure Manufacturing Safety

Using AI to Enforce Safety Compliance in Manufacturing

Records 16 to 30 of 68

First | Previous | Next | Last

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

Manufacturing and Automation - Featured Company

.jpg)