Micro Molding - The Need for Collaboration and DfM

TOYOTA Motorsport GmbH and 3D Systems Join Forces to Drive Innovation for Automotive Industry

STANLEY+Techstars Accelerator Announces Second-Annual Class

Renishaw showcases AM capabilities at RAPID + TCT

ManufacturingTomorrow - Special Tradeshow Coverage

RAPID + TCT

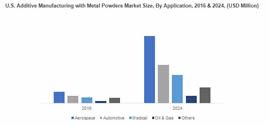

Additive Manufacturing with Metal Powders Market to surpass 4.5 kilo Tons Consumption By 2024

Carbon and Ford Expand Collaboration to Digitally Manufacture New Durable, End-Use Parts

How Real Value of Metal Additive Manufacturing Can Be Leveraged for Automotive Production

Philips' Lightbulb Moment: 3D Printing Becomes Essential Production Thinking

3D Printing: Head and Shoulders Above the Rest

ManufacturingTomorrow - Special Tradeshow Coverage

IMTS 2018

Victrex: New Advanced PAEK Product Designed for Additive Manufacturing

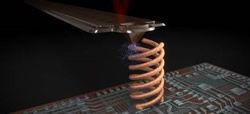

FluidFM® μ3Dprinter - A new function allows unique pinpoint metal additive manufacturing

The ADDere System by Midwest Engineered Systems

ManufacturingTomorrow - Special Tradeshow Coverage

RAPID + TCT 2018

Records 16 to 30 of 45

First | Previous | Next | Last

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Manufacturing and Automation - Featured Company