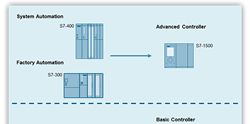

Upgrading for Industry 4.0: How Siemens S7-1500 Migration Solves Hidden Legacy Challenges and Why Modern Manufacturing Can't Afford to Wait

This article explains why migration to the S7-1500 platform is becoming urgent, the hidden challenges engineers face during transition, and how modern PLC architecture supports Industry 4.0 readiness, improved reliability, and long-term performance.

Driving Performance Improvement on the Shop Floor with Production Data

One of my favorite customer lines is, "I need parts, not charts." And that really captures what Datanomix is about: helping manufacturers solve real business problems by clearly showing what's happening on their shop floor.

Rugged Surface Pro xCase with Badge Readers Elevates Workforce Safety & Mustering for Umicore

When global materials technology and recycling leader Umicore set out to modernize employee tracking and emergency mustering processes, they turned to Savance Workplace for a customized digital workforce management solution.

2025 Top Article - Common Misconceptions Manufacturers have about AI

With over 25 years of experience advising mid-market companies, Ghori provides a grounded yet progressive-looking take on where manufacturers should focus, what misconceptions to avoid, and how to get started without overhauling everything.

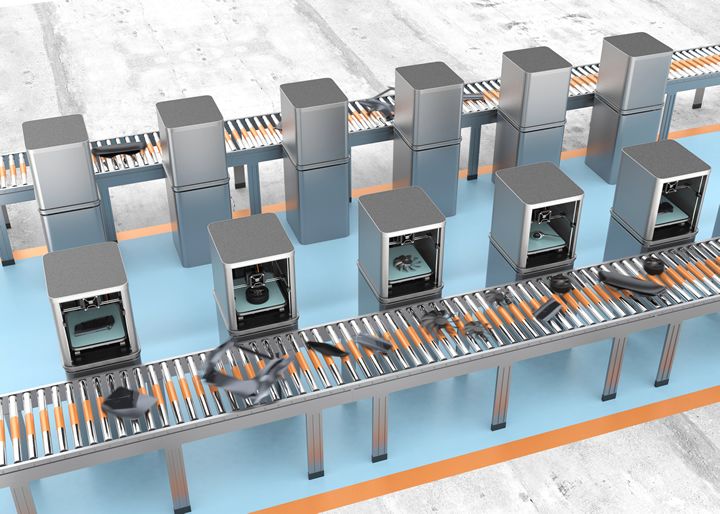

2025 Top Article - AUTOMATION IS UNLOCKING THE FUTURE OF AM SERVICES

In this article, I want to dive into the role automation plays in the approach to AM services, highlighting the benefits it delivers to customers, how it drives operational efficiency, and why it's essential for the future of this industry.

2025 Top Article - Monitoring Tools for Manufacturing Plant Maintenance

Electrical power delivery systems are usually the most impactful on plant operation. The cost of failure of certain pieces of equipment can quickly escalate into multi-millions of dollars of equipment replacement costs and production downtime.

2025 Top Article - How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

With lower barriers to entry, small and mid-sized manufacturers have more opportunities than ever to integrate industrial 3D printing into their operations while avoiding the hurdles that once held them back.

2025 Top Article - The Rise of AI in Manufacturing to Collect and Use Data

While AI and machine learning systems typically require around two years to collect enough data to reach their full potential, manufacturers can start seeing benefits almost immediately with basic analysis tools and dashboards.

Case Study from Nord - A Heavy Lift

How OMi Crane Systems works with NORD DRIVESYSTEMS to keep manufacturing moving. For OMi Cranes and its customers alike, having a reliable drive system supplier isn't just about convenience, it's about keeping material moving efficiently and without fail.

Energy-Efficient Manufacturing 4.0: Integrating Smart Drives, LED Displays, and IoT for Sustainable Factories

Energy efficiency in manufacturing means producing the same or higher output while consuming less energy. It is measured by key metrics such as energy intensity (kWh per unit produced) and power utilization rate.

How AI, Robotics, and Digital Twins are Transforming Modern Production Environments

I'm most excited about Cognitive AI becoming the factory's operating system, and cobots will effectively program themselves through natural language, teach-by-demonstration, and auto-generated PLC/robot code.

The Rise of the Invisible Workforce: The Most Important AI Breakthroughs of 2025 for Packaging Manufacturers

For the packaging industry specifically — with its heavy reliance on document processing, planning logic, and throughput efficiency — the year proved one thing: AI is no longer a future advantage. It's a current competitive requirement.

Closing Europe's aerospace production gap - EDM automation as part of the answer

EDM removes material using controlled electrical sparks between an electrode and the workpiece submerged in dielectric fluid. This makes it possible to cut extremely hard metals into complex shapes with micrometre accuracy.

Designing for Deviation in Additive Manufacturing

To truly realise the potential of AM, we need to embrace a new design philosophy, one that doesn't just work around variation, but works with it. At Metamorphic, we call this approach Designing for Deviation.

Case Study from NORD - Perfectly MESHed

High-quality gear motors from NORD DRIVESYSTEMS are a crucial piece of the manufacturing puzzle for this Georgia-based automation provider.

Records 1 to 15 of 1793

Featured Product

OnLogic Karbon 520 Series of Scalable Rugged Computers

The OnLogic Karbon 520 Series of rugged computers is purpose-built to deliver unwavering performance and reliability in the face of extreme temperatures, vibration, and dynamic power conditions. Powered by the latest Intel® Core™ Ultra processors and validated by MIL-STD-810H testing, the Karbon 520 Series makes it possible to deploy dependable computing for AI at the edge, advanced automation, or critical remote and in-vehicle applications in even the most challenging environments.

Manufacturing and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.