Case Study from NORD - Perfectly MESHed

Why Compliance Documentation Matters in Electronic Recycling

Two Industry Leaders - One Goal: Maximum Process Reliability

NewsFender's 3D Printed Ballistic Fender Charts a New Course in Maritime Defense

Hatz Engines - Case Study from CSP US Inc.

How Flying S is Turning Data into a Competitive Advantage

Must-Have AI Features in your next ERP: Why AI-Enabled ERP Is a CEO's Best Investment

Organic Soda Producer Implements Traceability System in Just a Few Weeks

What's Your Factory's Lean Maturity Score?

Sustaining a Positive Manufacturing Workplace in an Evolving AI World

The Next Industrial Epoch is Here: Why Acting Now is a Strategic Imperative for Manufacturers

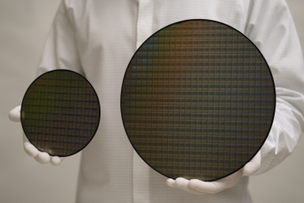

Why Automation, Not Wafer Size, Determines Semiconductor Fab Cycle Time

AI in Manufacturing: Why Now Matters

Using AI to Solve the "Execution Gap" in Manufacturing

The Library of Machine Malfunctions and Changing the Factory-Worker Relationship

Records 16 to 30 of 1794

First | Previous | Next | Last

Featured Product

NORD Delivers Powerful, Reliable Drive Solutions for Demanding Packaging Applications

Manufacturing and Automation - Featured Company