10 Common Supply Chain Issues & How to Solve Them

PILLARS OF TOMORROW - A hopeful vision of Government, Technology, and Human Dignity in harmony

Falling Behind Competition? Feel Like You Are Not Innovating Enough? Rethink Your CAD Platform.

Maximizing ROI with Mobile Automation: What the Data Shows

How Collision Awareness Systems Help Meet OSHA Forklift & Pedestrian Safety Guidelines

AI + Lean: How U.S. Manufacturers Can Blend Tradition with Technology

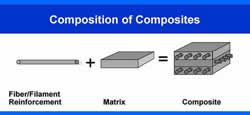

Comprehensive Guide to Composite Materials and Simulation

Maximizing OEE with Smart Selection of Electric Linear Actuators

Building a Culture of Team Performance at Paramount Machine with Production Monitoring

How Automation is Revolutionizing Pipe Fabrication Amid Labor Shortages and Rising Competition

The Promise & Risks of Physical AI's Self-Optimizing Factories & Human-AI Teaming

IDS: See. Align. Place.

Key Considerations for Maximizing Manufacturing Efficiency

Giving Blue-Collar Workers a Voice in Problem Solving - Without Slowing Production

Why edge AI alleviates the need for "flexible" data centers

Records 31 to 45 of 1793

First | Previous | Next | Last

Featured Product

Quality assurance in the manufacturing industry

Manufacturing and Automation - Featured Company