From Simple Fixes to Advanced AI: A Small Manufacturer's Guide to Industry 4.0

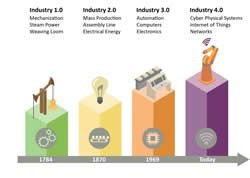

You might be aware that Industry 5.0 is aspirational for even the manufacturing who's who and while the jury is still out on what exactly the goal of 5.0 is, many experts observe that Industry 4.0 is far from complete

Manufacturing in the Age of Industry 4.0

The manufacturing industry is undergoing a profound transformation driven by the advent of Industry 4.0 technologies. This article examines the key technologies underpinning Industry 4.0 and their transformative impact on manufacturing.

Is Industry 4.0 Here? How AI is Transforming Manufacturing Today

In a recent SparkCognition webinar, "Top 3 Ways AI is Transforming Manufacturing," Andrea Schmidt and Bhavana Brar explored the topic of Industry 4.0, outlined the topline challenges and opportunities of adopting AI in the manufacturing industry.

Identifying, Developing, and Implementing Automation Solutions in Mid-Size Manufacturing

Our automation work provides opportunities for the upskilling of existing labor through the maintenance and programming of automation solutions and creates cost savings that make increased pay possible.

Advancing Industry 4.0 with AI

AI can provide superpowers to operators. But that can only happen if it's highly accessible and manageable. We give engineers purpose-built engineering solutions that augments their work.

Automation Alley announces new year-long format for Integr8 event

New approach will offer up to a dozen Integr8 roundtables series events exploring Industry 4.0 topics and an Integr8 Roundtable Summit on Oct. 3

Industry 4.0: Embracing a Smarter Future

Our software brings a fundamental impact from three perspectives: process and product quality control, production optimization, and the agility required for quick responses to market opportunities and contingencies.

Understanding the Role of Machine Vision in Industry 4.0

Today it is being applied to diverse areas such as monitoring processes for predictive maintenance, and robotic guidance that makes it possible for robots to safely work with and respond to human interactions.

How SASE Helps Overcome Security & Connectivity Challenges In Manufacturing

The manufacturing industry is undergoing a major transformation. Everything from production to supply chain to logistics is getting digitized and technologies like Robotic Process Automation (RPA), AI and the Internet of Things are ushering in a new era of smart factories.

How to Upskill Frontline Employees as Industry 4.0 Gains Traction

Digitization, automation, and artificial intelligence in manufacturing have paved the way for new production methods. If employees are going to take on new responsibilities and operate connected devices, they need to be upskilled and trained accordingly.

How LiDAR Is Paving the Way for Industry 4.0

LiDAR doesn't typically appear on disruptive Industry 4.0 technologies lists, but it may serve a foundational role in preparing facilities for this transition. Here's a closer look.

The Case for B2B Digitization at the Customer Level"¦ Especially for Manufacturers

Industry 4.0 and IIoT were supposed to improve forecasting, reduce supply chain snarls, and allow manufacturers to better plan production. But the overwhelming challenges of the pandemic and its aftermath show how far the industry still needs to go.

Wireless Charging Enables Industry 4.0 Implementation with Mobile Robots

The latest wireless charging solutions use techniques based on the principle of electromagnetic induction. When an alternating current is passed through an induction coil on the transmitter side, an oscillating magnetic field is created.

Coping With Rising Energy Prices - Can Manufacturers Remain Profitable Against Energy Uncertainty?

There is currently no end in sight for increasing energy costs. Nevertheless, it's an opportunity for manufacturers to reevaluate their current supply chains and internal processes, and embrace more energy efficient production through Industry 4.0.

Scaling Operational Excellence in the Oil and Gas Industry

As more oil and gas companies gear up for Industry 4.0 in the wake of COVID-19 this white paper explores some of the core technologies-Digital Twins, Industrial IoT Platforms, Big Data analytics, Artificial Intelligence, and more-that accompany digital transformation.

Records 1 to 15 of 201

Featured Product

NORD Delivers Powerful, Reliable Drive Solutions for Demanding Packaging Applications

When you need quality, flexibility and high efficiency, NORD has you covered with complete drive solutions for primary and secondary packaging, end-of-line packaging, and higher-level applications. NORD supports you through the entire life cycle of your drive systems with pre-sales engineering support, online tools, and a global service network. Drive systems for both vertically and horizontally networked technology with all the options for sensor incorporation and integration into the higher-level control system.

Manufacturing and Automation - Featured Company

MRPeasy

MRPeasy is a seriously powerful and easy to use ERP software for small manufacturers that gives you everything you need to manage your manufacturing and distribution processes. Integrating sales, procurement, inventory, production, finances, and your team, it provides you with an accurate real-time overview of your operations.

MRPeasy is trusted by 2000+ small manufacturers worldwide, 700+ of which are based in the US and Canada. Our users report a 54% average improvement in the overall performance of their business and a 42% increase in on-time deliveries.

Try for free, no credit card needed.