Service buses and their impact on digitalization

MOM Vs MES, Which is best for Industry 4.0

What Does Digital Manufacturing Mean and How Can We Move Toward It?

Applying ISA-95 in an Industry 4.0 world

To Overcome Capacity Constraints, Industry 4.0 Implementations Must Follow These 3 Steps

Interwire 2021 Trade Exposition - Industry 4.0 in Wire Manufacturing

Next-Gen Technologies to Navigate Key Shifts in Industrial Manufacturing

Automatic Photo Portal for the Documentation of Intralogistics Processes

Managing Obsolescence in Industry 4.0 - Obsolete Doesn't Mean Game Over

3 Ways to Improve Industry 4.0 OEE

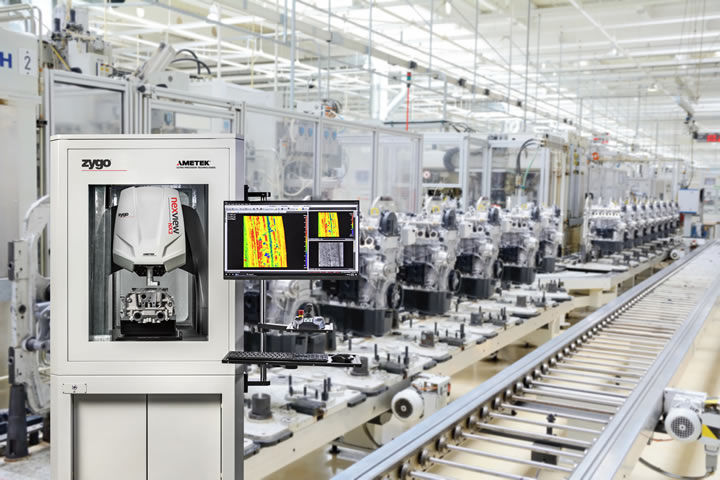

METROLOGY & INDUSTRY 4.0

To Adopt Industry 4.0, We Must Look to the Lighthouses

How Being Bold Brings Smart Automation Solutions

Is Industry 4.0 a Pipedream?

How Is the IoT Changing Pumping Systems Today?

Records 16 to 30 of 201

First | Previous | Next | Last

Featured Product

Model TR1 Tru-Trac

Manufacturing and Automation - Featured Company

.jpg)

.jpg)