Successful use of Carbon-composite Windform® XT 2.0 and professional 3D printing in the construction of 1P PocketQubes flight-ready

World's first 3D printed FRP footbridge paves way for circular composites

Additive Manufacturing for Production: Benchmarking Against Traditional Alternatives

Reduce Down Time with Torque Limiters

Vapour Degreasing - The Answer to Cleaner Components

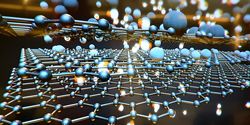

CRP Technology and Windform® Materials for 3D Printing are Driving AM Revolution

A Strong Impression

Hybrid Composites Help Manufacturers Get the Best of Both Materials

The Fall of Friction in Bearings

Manufacturers Replace Metal with Plastic to Reap Benefits of Plastic Resins While Maintaining Integrity of Metals

How Robotics Has Helped The Manufacturing Industry

Time to fight corrosion - for the environment's sake

The push and pull of composite manufacturing

Challenges in Aerospace Innovation in 2019 and Solutions for 2020

Composites for Car Part Manufacturing

Records 16 to 30 of 34

First | Previous | Next | Last

Featured Product

Rapid Prototyping with the Modular Motor Series

Manufacturing and Automation - Featured Company

.jpg)