The Evolution of Additive Manufacturing: How Automation Redefines Post-Processing Standards

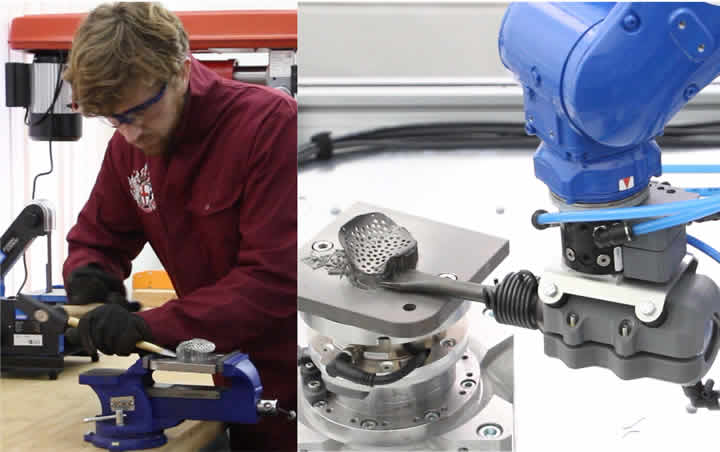

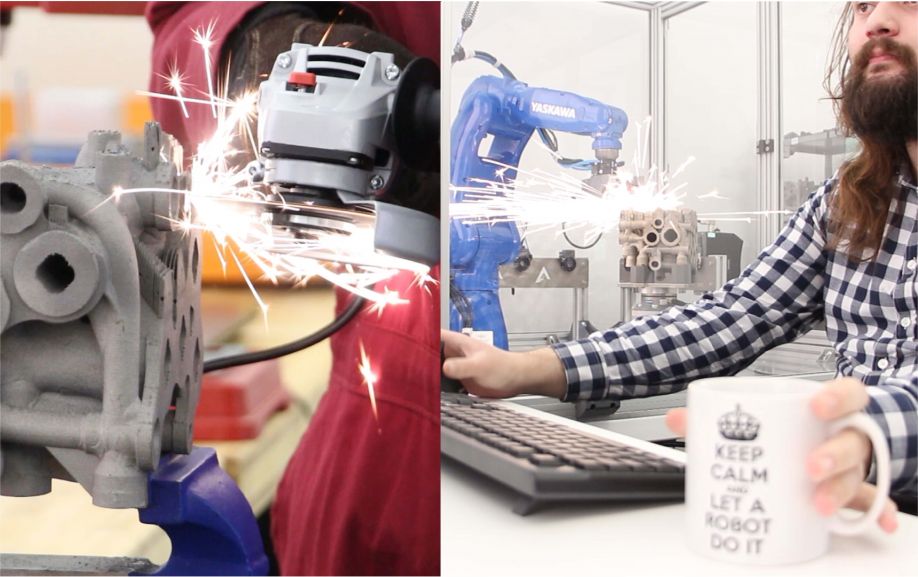

THE RISE OF AUTOMATION IN METAL AM POST-PROCESSING - TRANSFORMING THE INDUSTRY WITH PRECISION AND EFFICIENCY

NANO DIMENSION'S TERA 250vx ENHANCES ACCUMOLD'S MICRO INJECTION MOLDING SERVICE

The Future of Computer Aided Manufacturing & Fabrication

What's in store for 2024: Top 5 industry trends

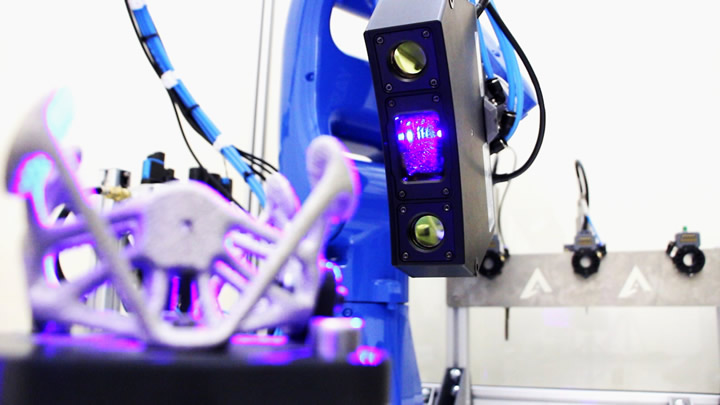

This 3D printer can watch itself fabricate objects

Expanding US-based Additive Manufacturing Services

Companies Collaborate to Build Giant Guitar Installation in Liverpool

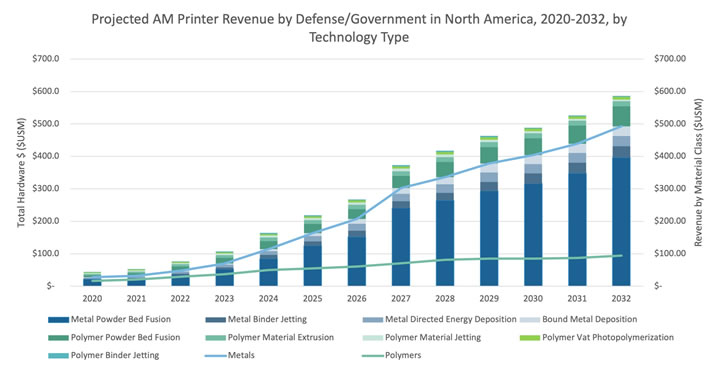

AM Research Publishes In-Depth Market Study on Additive Manufacturing for Military and Defense; Estimates $0.3B in Direct DoD Spend in 2023, Growing to $1.8B in 2032

Why 3D Metal Printing Is Key to the Future of Aerospace Engineering

CLEANING UP AM'S DIRTY SECRET

The Data Revolution Is Transforming Manufacturing-Don't Fall Behind

Additive at Scale Uses Essentium Technology to Create an Asset Tracking Solution in 60 Days

Precision Tools Hot Off the Press at Paul Horn

BEYOND THE SURFACE: THE POWER OF DENSITY DETERMINATION IN ADDITIVE MANUFACTURING

Records 31 to 45 of 779

First | Previous | Next | Last

Additive & 3D Printing - Featured Product

.jpg)

.jpg)