3D Printing and Sustainable Auto Manufacturing: A Glimpse into the Future

The excitement around 3D printing in the automotive industry is easier to understand in light of growing sustainability needs. While vehicles themselves may be the most obvious target for emissions reductions in this sector, the production side needs improvement, too.

Audi Sport Accelerates Design and Production Processes with trinckle Software and UltiMaker 3D Printers

When the new Audi E-Tron GT was introduced, the Audi Sport BÃ'llinger Höfe location in Heilbronn, Germany, rapidly needed almost 200 new tools, jigs and fixtures for its production. Designing these tools costs a lot of time.

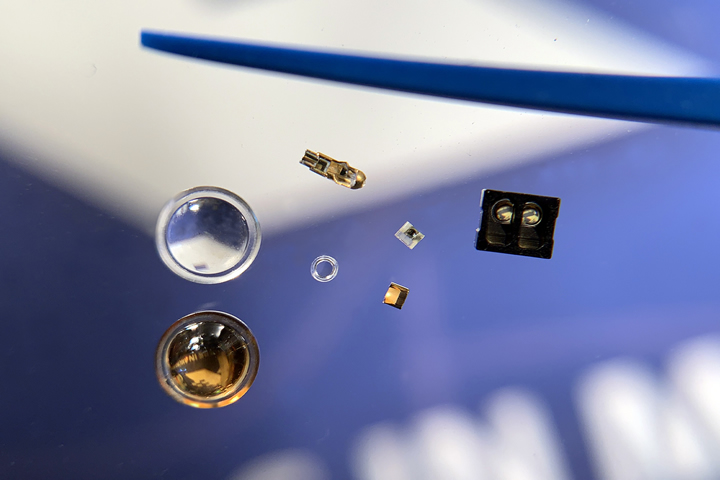

THE ROLE OF MICRO MOLDING IN THE PRODUCTION OF MICRO-OPTICS

Achieving the exacting tolerances required for these delicate micro-optic parts necessitates a deep and specialized processing knowledge that is distinctly different from that used for typical mechanical parts.

3D Printing Produces Engine Covers To Accelerate Aircraft Maintenance

How a specialized local engineering company supported a major airline during the pandemic with jet engine covers made with 3D printed molds.

Liquid-cooling VFD Increases Efficiency and Savings in Plastics Machinery

With operations running 24/7, 365 days a year, the company sought to upgrade its variable frequency drives (VFDs) to increase motor efficiency, thus reducing operational costs and enhancing energy efficiency throughout its extrusion processes.

Additive Manufacture: In-house 3D Printing versus Outsourced 3D Printing Service

In this 3-part series of articles, we will embark on a comprehensive exploration of 3D printing / additive manufacturing (AM), where our main focus is empowering you to make informed decisions about how to engage with the technology across an ever-evolving landscape.

Winds Of Change For Vestas: 3D Printed Tooling Transforms Wind Turbines

There aren't a lot of technologies that can propel towering wind turbines to new heights of time and cost efficiencies, but large-format additive manufacturing rose to the challenge and delivered with its eclectic range of applications.

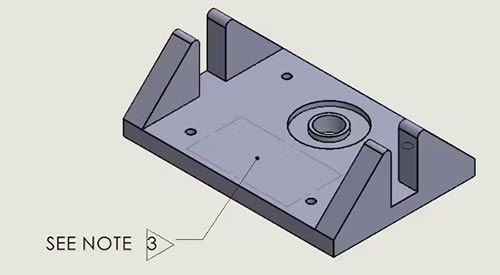

How to Create A Good Technical Drawing

Make sure your drawing undergoes all quality assurance and approval procedures. A drawing that is easy to follow and clearly defines your requirements is one of the first steps to a successfully manufactured part.

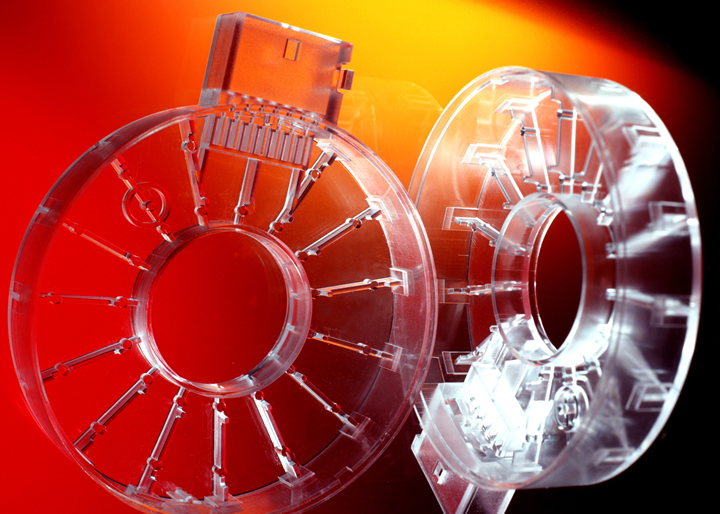

THE IMPACT OF 3D PRINTING ON MICRO MOLDING - A SYNERGISTIC APPROACH

The precision achieved in micro molding is not just about miniaturization, it's about reproducing complex shapes with exacting tolerances that are measured in microns repeatably.

3D Printing Powers Wind Turbine Research At TU Berlin

On average, wind turbine blades are a massive 80 meters long. When it comes to reengineering these towering blades, no other technology offers the freedom, precision, and adaptability to scale parts quite like 3D printing.

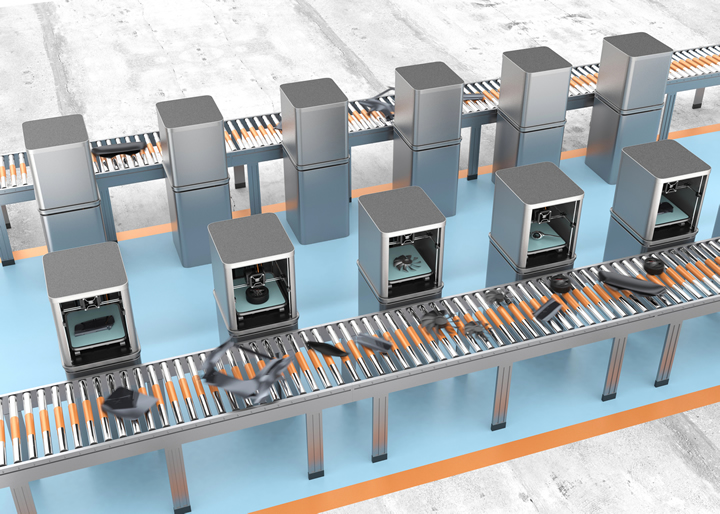

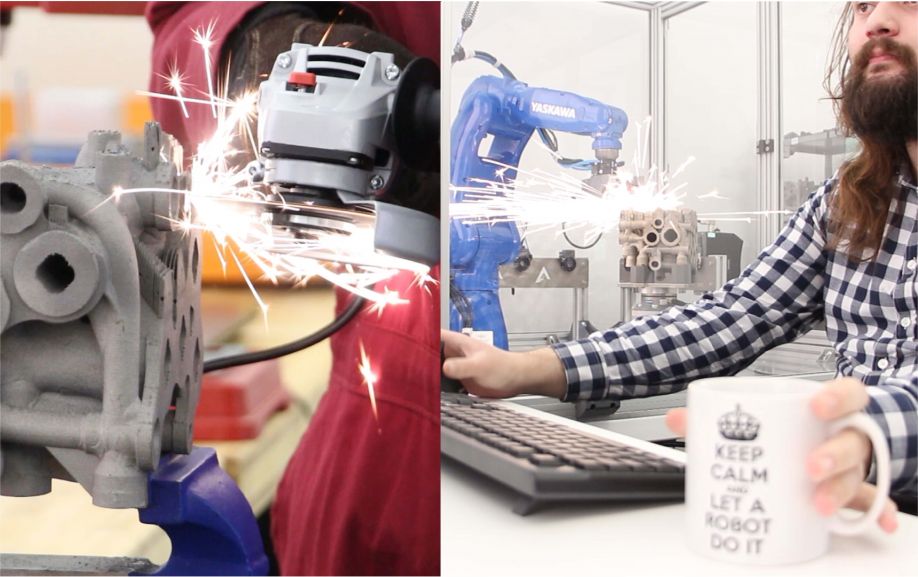

The Evolution of Additive Manufacturing: How Automation Redefines Post-Processing Standards

In 2024, post processing metal parts is still a bottleneck in the AM process chain because it is still very often a manual, labor-intensive, messy (filthy, actually) and sometimes risky task.

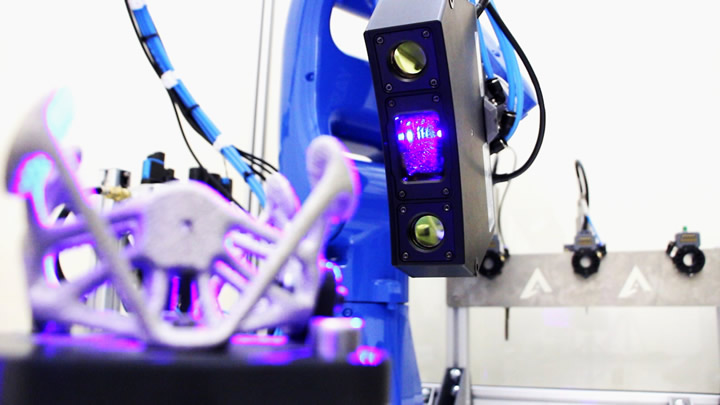

THE RISE OF AUTOMATION IN METAL AM POST-PROCESSING - TRANSFORMING THE INDUSTRY WITH PRECISION AND EFFICIENCY

We delve into how automation in metal AM post processing is setting a new industry standard, and how companies like Rivelin Robotics are leading this change with their Netshape® Robots to unlock new productivity and efficiency gains.

NANO DIMENSION'S TERA 250vx ENHANCES ACCUMOLD'S MICRO INJECTION MOLDING SERVICE

Today, Micro-Additive Manufacturing (Micro-AM) solution like the Tera 250vx from Nano Dimension can additively manufacture or 3D print micro parts and components only previously possible through the use of micro injection molding.

The Future of Computer Aided Manufacturing & Fabrication

Playing a key role in ensuring that automation is incorporated into the fabrication process helps to keep things moving along as quickly and efficiently as possible for manufacturing businesses around the world.

What's in store for 2024: Top 5 industry trends

The manufacturing industry is undergoing significant changes due to the swift advancement of technology and evolving global dynamics.

Records 1 to 15 of 759

Additive & 3D Printing - Featured Product

Get RFQs on Die Casting, Stamping, and Extrusion With Xometry, Your Source for Custom Parts

Xometry is your source for custom parts. Now, in addition to getting instant quotes on 3D Printing, CNC Machining, Sheet Metal, and Injection Molding, customers can create and send RFQs for die casting, stamping, and extrusion work to our nationwide network of pre-vetted manufacturers with just a 2D drawing. You will receive and be able to review responses from qualified shops within 7 days on an advanced web-based RFQ management platform. To learn more go directly to our site to issue and RFQ today. Stop wasting time managing RFQs through email and by phone, and start issuing RFQs at scale and in the cloud.

.jpg)