Create Tomorrow's Manufacturing Talent Today With These 8 Simple Strategies

Strategies to Tackle Knowledge Drain in American Manufacturing

Decoding the Magic of KPIs: Beyond Metrics, Towards Operational Excellence

Minimizing Unplanned Downtime: Strategies for Maximizing Productivity in Your Plant

Security Challenges For Smart Factories - How Does SASE Help?

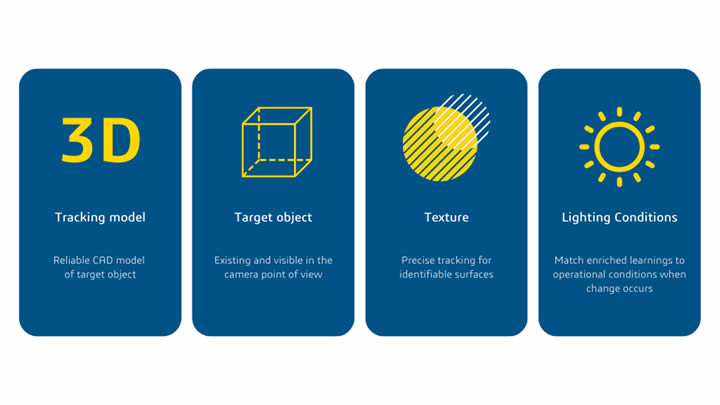

Do You Know the Role of Tracking in Augmented Reality?

The most compact Motion Control System on the market

Three layers of predictive maintenance - New horizons in a world of AI and Big Data

Revolutionizing Sustainability: igus Unveils AI-Driven Solutions for Industry 4.0 at Hannover Messe

Lean is the Future of Manufacturing

How Small Manufacturers are Building a Business Case for Robotics

How ML helps manufacturers maintain safer workplaces

Factories of the future - What will manufacturing facilities look like in 2044

THE IMPACT OF 3D PRINTING ON MICRO MOLDING - A SYNERGISTIC APPROACH

The Benefits of MOM & MES and Why the Differences Matter

Records 16 to 30 of 764

First | Previous | Next | Last

Engineering - Featured Product

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)