Driving Performance Improvement on the Shop Floor with Production Data

One of my favorite customer lines is, "I need parts, not charts." And that really captures what Datanomix is about: helping manufacturers solve real business problems by clearly showing what's happening on their shop floor.

2025 Top Article - Common Misconceptions Manufacturers have about AI

With over 25 years of experience advising mid-market companies, Ghori provides a grounded yet progressive-looking take on where manufacturers should focus, what misconceptions to avoid, and how to get started without overhauling everything.

2025 Top Article - Monitoring Tools for Manufacturing Plant Maintenance

Electrical power delivery systems are usually the most impactful on plant operation. The cost of failure of certain pieces of equipment can quickly escalate into multi-millions of dollars of equipment replacement costs and production downtime.

2025 Top Article - The Rise of AI in Manufacturing to Collect and Use Data

While AI and machine learning systems typically require around two years to collect enough data to reach their full potential, manufacturers can start seeing benefits almost immediately with basic analysis tools and dashboards.

How AI, Robotics, and Digital Twins are Transforming Modern Production Environments

I'm most excited about Cognitive AI becoming the factory's operating system, and cobots will effectively program themselves through natural language, teach-by-demonstration, and auto-generated PLC/robot code.

Using AI to Solve the "Execution Gap" in Manufacturing

Max AI doesn't just bridge the execution gap - it sets a new standard for modern manufacturing. By acting in real time - watching, thinking, and doing - it removes the friction and firefighting that once consumed operators, supervisors, and planners.

The Library of Machine Malfunctions and Changing the Factory-Worker Relationship

The goal from day one was clear: build the definitive source of industrial reliability knowledge, and open it up to empower teams everywhere to shift from reactive troubleshooting to proactive control.

PILLARS OF TOMORROW - A hopeful vision of Government, Technology, and Human Dignity in harmony

For centuries, visions of the future have been dominated by dystopian warnings - cautionary tales of power gone wrong. Five Pillars of Tomorrow offers an alternative: a governance model where transparency, collective wisdom, and advanced AI safeguard human dignity.

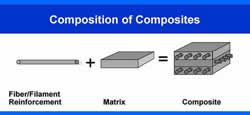

Comprehensive Guide to Composite Materials and Simulation

Composite simulation is crucial because it lets engineers explore designs, optimize performance, and spot failures digitally, saving tons of time and money compared to physical testing. It's challenging due to anisotropy, modeling delamination, and high computational cost.

The Promise & Risks of Physical AI's Self-Optimizing Factories & Human-AI Teaming

Physical AI is the difference between an algorithm that predicts a machine failure and an intelligent robot that can physically inspect the machine, identify the fault, and adapt its operation to prevent a shutdown.

Key Considerations for Maximizing Manufacturing Efficiency

It's true that advanced simulation tools have helped improve the efficiency and effectiveness of robotic workcell design and path planning, but it still remains an incredibly time consuming process.

Maximizing Operation Efficiency through Manufacturing Processes

Cross-functional collaboration isn't just helpful, it's the backbone of a smooth new product introduction. You can have the best design on paper, but if engineering, operations and supply chain aren't aligned from day one, you're setting yourself up for late-stage surprises.

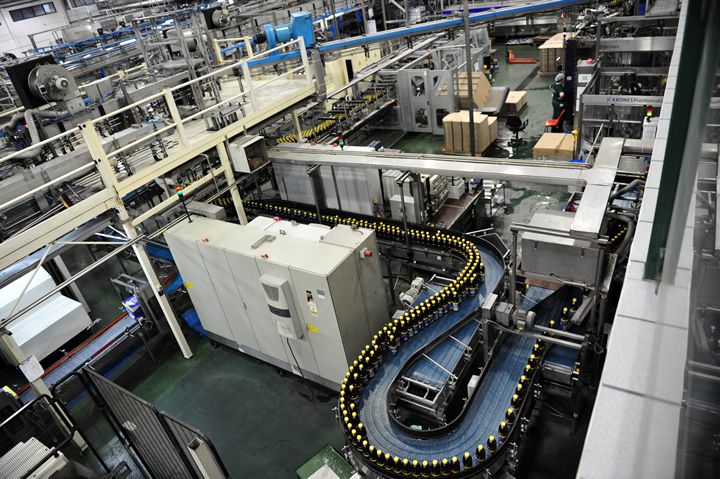

Talking PACK EXPO Las Vegas with Encoder Products Company (EPC)

We're featuring live demos of our newest encoders, including the LP1 Accu-LaserPro™ - a slip-free, high-accuracy laser encoder designed for packaging lines. Visitors will see how EPC encoders reduce downtime, simplify integration, and deliver long-lasting performance.

Driving Supply Chain Innovation Through AI and Process Optimization

AI and data analytics are game changers for the manufacturing industry's demand and shop floor agility. My team is currently developing an AI model that identifies irregular demand patterns and updates itself.

BigRep ALTRA 280, the Ultimate High-Temperature Industrial 3D Printer

The ALTRA 280 was engineered to solve a challenge that's persisted for years: reliably and affordably producing large, complex parts in both engineering-grade and high-performance polymers.

Records 1 to 15 of 175

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

The FLIR Si1-LD is an easy-to-use acoustic imaging camera for locating and quantifying pressurized leaks in compressed air systems. This lightweight, one-handed camera is designed to help maintenance, manufacturing, and engineering professionals identify air leaks faster than with traditional methods. Built with a carefully constructed array of MEMS microphones for high sensitivity, the Si1-LD produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments. The acoustic image is overlaid in real time on a digital image, allowing you to accurately pinpoint the source of the sound, with onboard analytics which quantify the losses being incurred. The Si1-LD features a plugin that enables you to import acoustic images to FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation. Field analysis and reporting can also be done using the FLIR Acoustic Camera Viewer cloud service. Transferring of images can be managed via memory stick or USB data cable. Through a regular maintenance routine, the FLIR Si1-LD can help facilities reduce their environmental impact and save money on utility bills.

Manufacturing and Automation - Featured Company

KEB America, Inc.

KEB America is a trusted manufacturer of industrial automation products in North America. We manufacture, assemble, and support our German-engineered suite of controls, drives, motors, brakes, and clutches at an ISO 9001:2015 certified, 150,000-square-foot facility in Shakopee, Minnesota.