Manufacturing and Automation - Articles, Stories & Interviews

Do You Know the Role of Tracking in Augmented Reality?

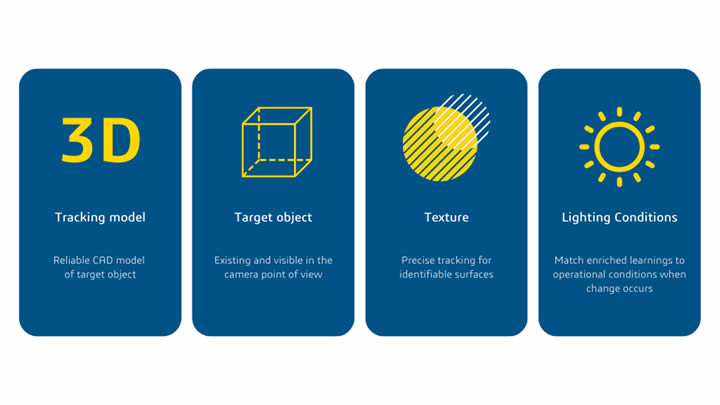

Tracking is used in the DELMIA Augmented Experience solution to identify the equipment to be assembled or inspected. Thanks to its 3D model, it simultaneously locates several elements at once, and displays the digital information required for the industrial process.

Automate 2024 Product Preview

Automate 2024 takes place May 6th - 9th in Chicago, Illinois. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Liquid-cooling VFD Increases Efficiency and Savings in Plastics Machinery

With operations running 24/7, 365 days a year, the company sought to upgrade its variable frequency drives (VFDs) to increase motor efficiency, thus reducing operational costs and enhancing energy efficiency throughout its extrusion processes.

Considerations for Choosing the Right Encoder for Your Application

Depending on the encoder, resolution is one of the most important calculations to understand. Accurate print landing, accurate conveyor speed, accurate satellite positioning, accurate elevator control all hinge on the resolution and type of encoder.

Additive Manufacture: In-house 3D Printing versus Outsourced 3D Printing Service

In this 3-part series of articles, we will embark on a comprehensive exploration of 3D printing / additive manufacturing (AM), where our main focus is empowering you to make informed decisions about how to engage with the technology across an ever-evolving landscape.

BOOSTING PANERA BREAD'S EFFICIENCY WITH CIMON'S PLC AND HMI SOLUTIONS

The initiative aimed not only to streamline operations but also to fit seamlessly within the limited space of retail restaurants, a challenge in the bustling food service industry.

The AI Imperative: Crafting Your Manufacturing Future

How does a business begin to build a compelling AI case? It starts with a problem worth solving. Here is how businesses can leap onto the AI train with a strategy that is as pragmatic as it is ambitious.

Manufacturing and Automation - Featured Stories

The most compact Motion Control System on the market

FAULHABER is introducing a new Motion Control System. More precisely: The world's smallest Integrated Motion Controller.

Unlocking Customer Experience: The Critical Role of Your Supply Chain

Cost implications play a pivotal role in delivering exceptional experiences for end-users. By optimizing expenses, businesses can allocate resources to enhance product quality and service delivery, ensuring customer satisfaction.

Three layers of predictive maintenance - New horizons in a world of AI and Big Data

The key difference between preventive maintenance and predictive maintenance is that the latter means completing maintenance only when needed, as opposed to scheduled intervals.

Manufacturing and Automation - News Headlines

Configit to Host 9th Annual Configuration Lifecycle Management Virtual Summit

Industry pros to explore best practices for orchestrating your product configuration data

OMNIVISION Launches New 9-megapixel Global Shutter Image Sensor for Industrial Machine Vision Cameras

To be demonstrated at the Automate Show, the OG09A is a 9-MP high-resolution global shutter sensor with a 1-inch optical format featuring PureCel®Plus-S technology that targets high-speed machine vision requirements

Rockwell Automation Expanding Presence in India with New Manufacturing Facility

New location will support supply chain resilience in Asia Pacific

Revolutionizing SMT THT Technology: Advanced AI Inspection with I.C.T AOI Machine

Amidst the dynamic world of Surface Mount Technology (SMT), where precision and efficiency reign supreme, manufacturers are tirelessly seeking inspection solutions that elevate accuracy and streamline production workflows. Enter SMT AOI AI Inspection Technology - a game-changing innovation fusing state-of-the-art artificial intelligence algorithms with advanced inspection capabilities. This transformative technology promises to redefine industry standards, delivering unparalleled precision and efficiency in SMT component inspection on a global scale.

Enhanced AI Inspection for SMT and THT Technologies

In the dynamic world of Surface Mount Technology (SMT), precision and efficiency are critical. Manufacturers worldwide seek inspection solutions that improve accuracy and streamline production processes. Enter SMT AOI AI Inspection Technology - an innovative solution that combines cutting-edge artificial intelligence algorithms with advanced inspection capabilities.

Manufacturing and Automation - Featured Product

Thermal Seal Inspection for Improved Quality and Efficiency

MoviTHERM's Thermal Seal Inspection (TSI) solution provides precise and reliable detection of defects in a variety of packaging types, including pouches, bags, blister packs, bottle caps, and more. By detecting defects in your packages, the TSI solution helps increase efficiency in your production line and ensures top-quality packaging is delivered to your customers every time. With state-of-the-art technology and an experienced team, MoviTHERM is dedicated to delivering accurate inspection solutions and peace of mind to its clients. Contact MoviTHERM today to learn more about their thermal seal inspection solution.

Manufacturing and Automation - Featured Company

ELATEC Inc.

ELATEC designs and manufactures RFID badge, card, and smartphone readers for user authentication and access control to manufacturing equipment. Our readers enable tracking of who performed what operation on what piece of equipment and when for quality control and operator safety. We have been in business for over 30 years. RFID is what we do-it is all we do. And our RFID technology is the most advanced available today. This is why we are a market leader in Europe and experiencing tremendous growth in the US. But as our customers will tell you, it is also due to our exceptional design expertise and technical support. We are easy to work with. And being easy to work with is critical to getting design engineers and product managers to move beyond their limited, traditional supplier base, who we have found is often not delivering the total value the customer needs today or will likely require tomorrow. We have a deep and comprehensive understanding of how to work with manufacturing equipment OEMs. At the core, ELATEC RFID readers are innovative due to their unique, flexible architecture and open API. This ensures smooth and easy integration with hardware systems and back-end software. OEMs and Integrators: you have a choice-a proven choice. We encourage you to discover ELATEC RFID if you have not already and learn what we can do together!