Manufacturing and Automation - Articles, Stories & Interviews

Ex-NASA Engineer Now Guiding Manufacturers to Greater Efficiency

David Altemir, Founder of Altemir Consulting manufacturing consultancy from Dallas, used to build rocket ships. Today, he has his feet firmly planted on the shop floor, helping manufacturers across America improve their operational efficiency.

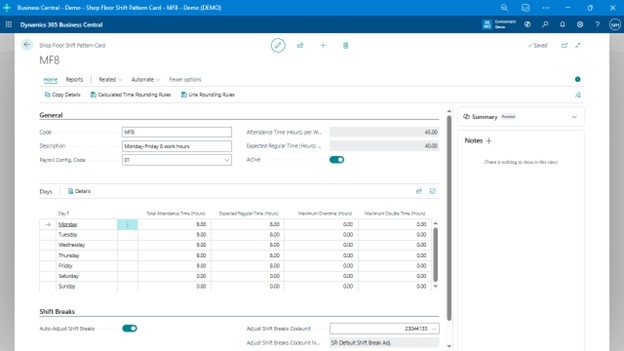

Why Manual Time Tracking in Business Central Is Costing Your Shop Floor More Than You Think

By automating time collection through barcode scanning, manufacturers gain precise labor costing, improved accountability, and a clearer picture of shop floor performance.

Smart Automation: How AGVs and AMRs Help Manufacturers Manage Rising Costs

The time is now to invest in scalable, cost-efficient automation deployments, keeping in mind the importance of power and data delivery solutions that support consistent, productive operations.

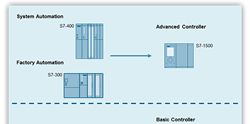

Upgrading for Industry 4.0: How Siemens S7-1500 Migration Solves Hidden Legacy Challenges and Why Modern Manufacturing Can’t Afford to Wait

This article explains why migration to the S7-1500 platform is becoming urgent, the hidden challenges engineers face during transition, and how modern PLC architecture supports Industry 4.0 readiness, improved reliability, and long-term performance.

Driving Performance Improvement on the Shop Floor with Production Data

One of my favorite customer lines is, “I need parts, not charts.” And that really captures what Datanomix is about: helping manufacturers solve real business problems by clearly showing what’s happening on their shop floor.

Rugged Surface Pro xCase with Badge Readers Elevates Workforce Safety & Mustering for Umicore

When global materials technology and recycling leader Umicore set out to modernize employee tracking and emergency mustering processes, they turned to Savance Workplace for a customized digital workforce management solution.

2025 Top Article - Common Misconceptions Manufacturers have about AI

With over 25 years of experience advising mid-market companies, Ghori provides a grounded yet progressive-looking take on where manufacturers should focus, what misconceptions to avoid, and how to get started without overhauling everything.

Manufacturing and Automation - Featured Stories

AI for Product Data Management: A Key Component for Smarter Manufacturing

.jpg)

AI improves data quality by reducing errors and inconsistencies introduced by manual intervention. Manual errors may not seem like a huge deal, but they can easily disrupt time-to-market or channel accuracy.

Discovering Manufacturing Bottlenecks Through AI and Machine Learning Analysis

.jpg)

Manufacturing slowdowns come from many sources. That diversity makes it challenging for executives to identify the top causes without help. Well-trained AI and machine learning algorithms can analyze the data and recommend suggestions for improvement.

How private 5G empowers manufacturers to maximize AI use cases

While Wi-Fi networks have historically met the basic wireless connectivity needs of some manufacturing operations, they increasingly fall short in more complex, high-demand industrial environments.

Manufacturing and Automation - News Headlines

The WAI Education Center expands online video training courses to meet evolving needs of today's wire & cable manufacturing workforce.

The online platform offers on-demand access to both ferrous and nonferrous courses delivered by industry experts. With interactive content, multimedia resources, and up-to-date technical information, the platform empowers students to expand their knowledge and skills at their own pace, from any location. Each course follows a structured, user-friendly format, combining industry-leading content with practical application for real-world scenario

Teknic's new EtherNet/IP integrated brushless servo motors: available to buy online today.

Available models from 1/8 to 7.7 hp peak, with velocity control models starting at $260 and position control starting at $599 (qty. 1-9).

Software Solutions Named ERP Product Leader from Frost & Sullivan

Independent analyst recognizes ECI's industry-specific ERP and practical AI approach for SMB manufacturers

Flexxbotics Releases Free Download of Software-Defined Automation for Manufacturing Autonomy

Flexxbotics free download is not a trial or evaluation version. It includes the SDA runtime, Studio, and API with no time limits, capacity restrictions, or disabled capabilities.

ABCorp 3D Opens New Tennessee Additive Manufacturing Center, Celebrates Five Years of 3D Printing Excellence

ABCorp 3D's new 60,000-square-foot advanced manufacturing center in Columbia, Tennessee expands its U.S.-based capacity for high?volume, secure additive manufacturing across a broad range of 3D printing applications and materials. The new facility strengthens ABCorp 3D's ability to serve fast?growing sectors while improving speed, scalability, and distribution.

Manufacturing and Automation - Featured Product

ResinDek® TRIGARD® ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC® (www.resindek.com) created the TriGard® ESD Ultra finish for its ResinDek® engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Manufacturing and Automation - Featured Company

The Wire Association International, Inc. (WAI)

The Wire Association International (WAI), Inc., founded in 1930, is a worldwide technical society for wire and cable industry professionals. Based in Madison, Connecticut, USA, WAI collects and shares technical, manufacturing, and general business information to the ferrous, nonferrous, electrical, fiber optic, and fastener segments of the wire and cable industry.

WAI hosts trade expositions, technical conferences, and educational programs.