5 Signs it's Time to Hire a Fractional CFO

For many small to mid-sized manufacturers, hiring a full-time CFO isn't economically feasible. That's where a fractional CFO-a part-time, high-level financial expert-can step in to transform the business.

Leading with Limits

Through diligent education and awareness of this evolving landscape, businesses and their partners can thrive by using emerging technologies and position themselves competitively.

COMPOSITE CONDUCTOR CORES ENABLE AMERICAN POWER MODERNIZATION

Surging electrical demand from AI-enabling data centers and increased urban power consumption, as well as vast renewable energy production, require upgraded electrical infrastructure.

From Legacy to Leading: How Manufacturers Can Bridge the Integration Gap

Despite big bets on AI, IoT and cloud platforms, many manufacturers are stuck at the starting line. Why? Because they're trying to race ahead while dragging decades-old systems behind them - and, those systems won't talk to each other.

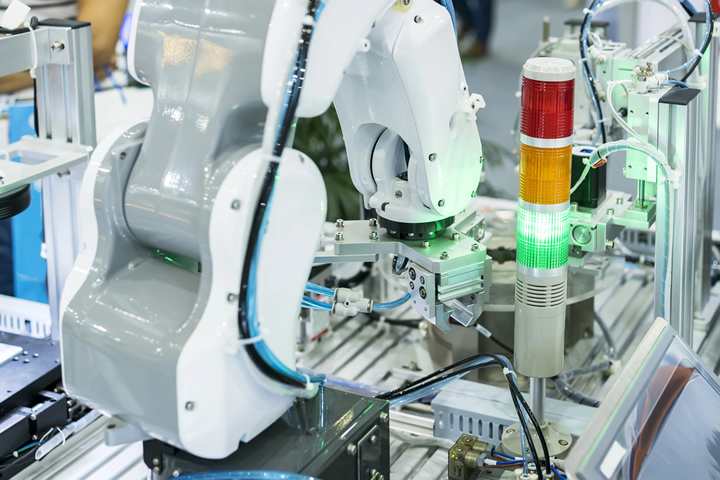

From Displacement to Empowerment: How Robotics Developers Can Lead the Workforce Reskilling Revolution

As automation continues to integrate into our factories, warehouses, and supply chains, the conversation around workforce transition and reskilling has become one of the most urgent and defining challenges of our time.

Non-Destructive Testing (NDT) methods with Digital Inspection Technologies

By combining NDT with digital tools like AI, machine learning, and real-time monitoring, they can quickly identify issues, track trends, and make more informed decisions. This integration improves accuracy, reduces inspection time, and enhances overall product reliability.

How to Build a Proactive Obsolescence Management Plan for Critical Components

All products eventually become obsolete, which can have significant consequences when it affects critical components. Proactive strategies can mitigate these risks. How can organizations develop an effective obsolescence management plan or refine their current one?

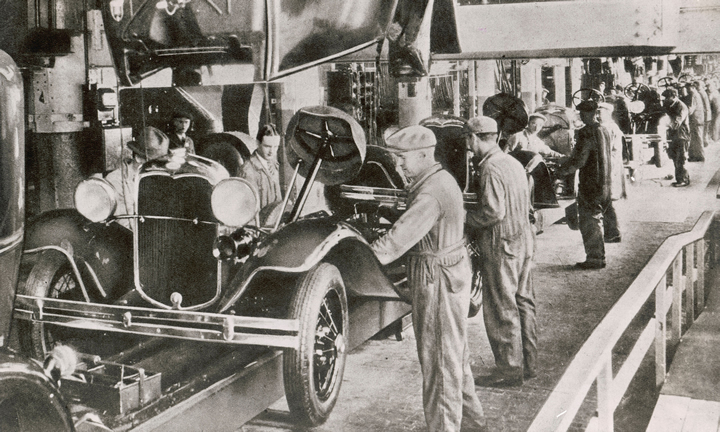

Outlook for manufacturing to 2028

Technological advancements, consumer demand and global markets have always had the power to change the manufacturing industry, and in the coming years it is inevitable that we will see some big changes.

Top Use Cases of RPA in Warehouse and Inventory Management

RPA is no longer experimental in logistics-it's essential. Whether reducing order processing time, maintaining inventory accuracy, or automating invoice reconciliation, the use cases here show how robotic automation drives speed, accuracy, and cost-efficiency at scale.

Automating the 'last mile' of package deliveries

The use of optical character recognition enables parcels to be quickly scanned and assigned to a bin that will collate all the packages for a delivery area. Automation allows line speeds to be increased and reduces sorting errors, boosting efficiency.

Bridging the Communication Gap: A Business Case for AI in Manufacturing

English may be the language of business, and yet only 20% of global workforces speak it fluently. The communication gaps in the global, diverse industry of manufacturing have been critically overlooked.

Do Our Youth Hold the Key to Manufacturing's Skills Crisis?

Matt Eden, Engineering Director at cable assemblies manufacturer GTK, makes the case for answering the UK's skills gap problem with forward-thinking hiring practices.

How to Achieve Sustainable Production?

By leveraging cutting-edge digital solutions, sustainable production transforms traditional manufacturing processes by increasing efficiency, reducing waste, and conserving energy, pushing industries toward a more resilient and eco-friendly future.

The Future of IoT Analytics: How AI and Big Data are Changing the Industrial Sector

Imagine trying to keep track of everything happening in a giant factory, where robots build cars, sensors check the temperature, and cameras inspect for defects. Without a system to connect all that information, it would be chaotic.

Adjusting M&A Strategies in Response to Changes in Global Trade Policies and Tariffs

Many of the deals announced in the first quarter were initiated last year, during a period of growing optimism driven by the prospect of a business-friendly US administration. However, recent trade policies have dampened optimism, and uncertainty has returned to the market.

Records 1 to 15 of 665

Automation & IIoT - Featured Product

KEB VFDs for High Speed Motor Control

KEB's VFDs are the key to unlocking peak performance in your high-speed machinery. Engineered for precision control, even without feedback sensors, our F6 and S6 drives utilize advanced software and high-frequency output. This ensures smooth operation, reduced vibration, and optimal efficiency. Whether you're building turbo blowers, power generation systems, or other high-speed applications, KEB VFDs deliver the reliability and performance you need.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)