Automate 2025 Product Preview

VE Day at 80: Lessons from Wartime Manufacturing for a Modern Britain

How to Ensure Your Corrective Actions Work, and Keep Working

Adapting to Change: How CPQ Software Is Shaping the Future of Custom Manufacturing

Custom linear motion solution drives Swiss river restoration research project

In the industrial maintenance space, knowledge is key for employee retention

This Is the Most User-Friendly Manufacturing Software, Says Manufacturing Consultant

Energy Efficiency in Manufacturing and Data Management

Advances in Preventive Maintenance Are Refining the Manufacturing Supply Chain in 2025

Renishaw helps Tronosjet Manufacturing achieve FAA certification

Automate 2025 Q&A with Onlogic

MES Implementation Strategies for Cost Savings and Improved Reporting

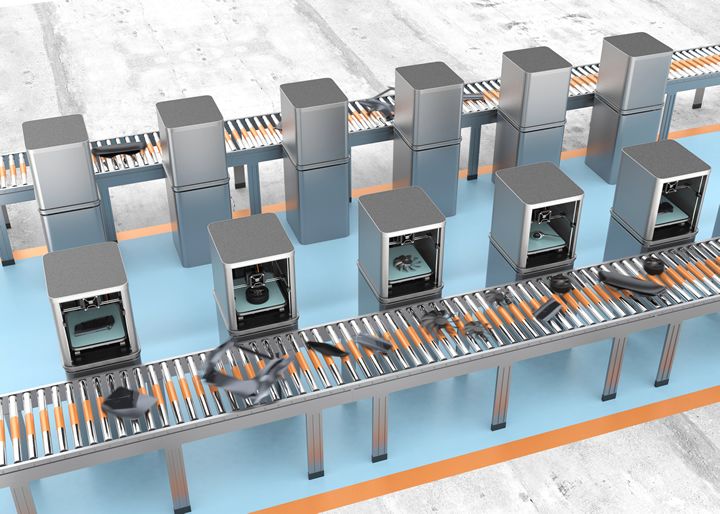

How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

Securing Intellectual Property in 3D Printing: A New Era of Protection

Will AI Take My Job in Manufacturing?

Records 31 to 45 of 1915

First | Previous | Next | Last

Engineering - Featured Product

.jpg)

.jpg)