At Automate, visitors will get hands-on experience with our range of rugged computers, built for industrial environments, and learn about the latest developments in this field. We'll also be demonstrating an AI vision system designed for real-world automation challenges.

Automate 2025 Q&A with Onlogic

Automate 2025 Q&A with Onlogic

Q&A with | Onlogic

Tell us about your company.

OnLogic is a global industrial computer manufacturer who designs highly-configurable, solution-focused computers engineered for reliability at the IoT edge. Our systems operate in the world’s harshest environments, empowering customers to solve their most complex computing challenges, no matter their industry. Founded in 2003, the company has offices in the U.S., the Netherlands, Germany, Taiwan and Malaysia. OnLogic has helped more than 70,000 customers worldwide advance their ideas with computers that are designed to last, built to order and delivered in days. Learn more at onlogic.com.

Your company will be exhibiting at Automate, what is it that makes this an important event for your company?

The Automate tradeshow is important for OnLogic. We get to bring our latest advancements in rugged, fanless industrial computers and share them with the engineers and integrators shaping the future of automation. We're not just displaying our hardware; we're demonstrating how it empowers the latest developments in robotics, machine vision, and AI. This is where we connect, learn, and have the chance to embrace our role in driving the next wave of industrial automation.

What makes your booth a must visit for Automate Attendees?

The OnLogic booth (#3447) offers attendees a chance to explore practical applications of industrial computing. We will be joined by our technology partner, ZEDEDA, to demonstrate a comprehensive, streamlined solution for deploying and managing edge applications and workloads. ZEDEDA's cloud-native intelligent edge orchestration, coupled with OnLogic's high-performance, industrial edge hardware ensures optimal, reliable, and scalable performance while minimizing on-site resource requirements in demanding environments. Visitors will get hands-on experience with our range of rugged computers, built for demanding industrial environments, and learn about the latest developments in this specialized field. We'll also be demonstrating an AI vision system designed for real-world automation challenges. Plus, join us for a happy hour to network and unwind.

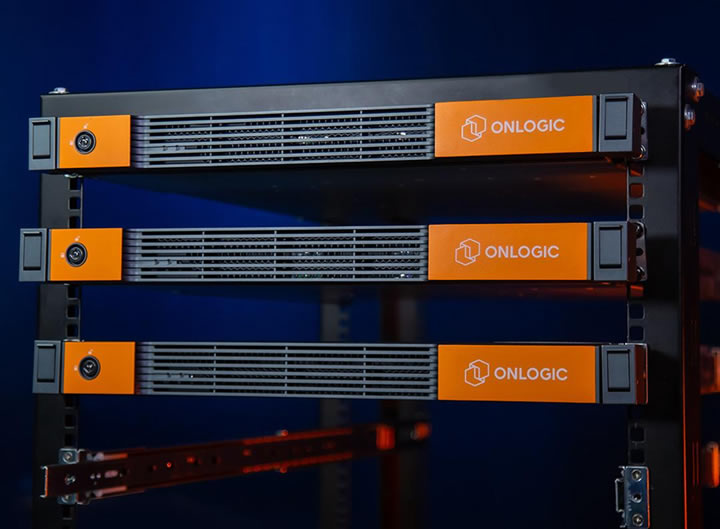

In addition to their line of compact industrial and rugged computers, the new OnLogic Axial AX300 Edge Server will also be on hand at Automate. The system is engineered specifically for advanced data analytics and AI at the edge.

Automate has many educational sessions, forums & Demo’s, is your company involved in any of them this year?

Our VP of Edge AI Solutions, Michael Kleiner, will be participating in the A3 Automate Preview Series webinar, Automate Now: How to Get Started. This webinar is designed to guide businesses through the initial steps of automation implementation. From assessing your current processes and identifying automation opportunities to selecting the right technologies and building a roadmap, this session will provide practical advice and actionable insights about successfully navigating the automation landscape. Tune on April 10, 2025 from 11 AM - 12 PM. Register: https://www.automate.org/webinars/automate-preview-series-automate-now-how-to-get-started

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

We’re particularly keen to observe the advancements in edge-deployed AI solutions, mirroring our own focus. We’ll be looking for demonstrations of advanced machine vision systems, similar to what we enable through our rugged edge computers paired with AI accelerators, that offer real-time defect detection and process optimization. We’re excited to see how companies like NVIDIA, with their Jetson platform, are powering ruggedized robotics and AMRs, showcasing how edge computing enhances responsiveness in dynamic industrial environments. We’ll also be seeking real-time predictive maintenance solutions, like those we facilitate with our robust edge hardware and partner software, that utilize sensor data and AI to minimize downtime. For educational sessions, we’ll prioritize those discussing cybersecurity for edge AI, scalability of distributed systems, and the convergence of AI, robotics, and IoT.

Manufacturing is undertaking rapid advancements, be it automation, robotics and of course AI. How is your company's services and products utilizing AI now to improve business?

OnLogic is addressing the manufacturing sector's rapid AI integration by providing rugged industrial computers designed for edge deployment, crucial for real-time data processing in demanding environments. Our focus is on enabling practical AI applications like predictive maintenance and quality control, helping manufacturers analyze data and optimize processes without relying on constant cloud connectivity. We offer AI consulting services to guide businesses through the complexities of implementing these edge AI solutions, ensuring they can effectively utilize AI to improve efficiency and make informed decisions on the factory floor. Learn more: https://www.onlogic.com/services/ai-consulting/

Give us your thoughts on what the future holds for manufacturers and automation.

At OnLogic, we see the future of manufacturing and automation as inextricably linked to the continued evolution and integration of edge computing and AI. We see a significant shift towards more decentralized, intelligent systems that can operate with greater autonomy and efficiency.

We anticipate a surge in the adoption of edge AI for real-time decision-making on the factory floor. This means more sophisticated machine vision systems for quality control, predictive maintenance powered by sensor data analysis, and highly adaptable robotic systems that can respond dynamically to changing conditions. These advancements will drive increased productivity, reduce downtime, and enhance overall operational efficiency.

We believe that the convergence of 5G, IoT, and edge computing will create a more interconnected and responsive manufacturing environment. This will enable seamless data flow between devices and systems, leading to better coordination and optimization of processes. We also see that cybersecurity will continue to be paramount, and that solutions will need to be developed to protect these increasingly complex and interconnected systems.

The trend towards customization and on-demand manufacturing will also accelerate, driven by the need for greater flexibility and responsiveness to customer demands. Automation will play a crucial role in enabling this shift, with robotic systems and AI-powered workflows allowing for more agile and efficient production.

Ultimately, we envision a future where manufacturing is more intelligent, efficient, and sustainable. Edge computing and AI will be the key enablers of this transformation, empowering manufacturers to optimize their operations, reduce waste, and create more resilient and adaptable supply chains. We're committed to providing the rugged, reliable hardware and expert guidance needed to make this future a reality.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

OnLogic

OnLogic is a global industrial computer manufacturer who designs highly-configurable, solution-focused computers engineered for reliability at the IoT edge. Their systems operate in the world's harshest environments, empowering customers to solve their most complex computing challenges, no matter their industry. OnLogic has helped more than 70,000 customers worldwide advance their ideas with computers that are designed to last, built to order and delivered in days.

Other Articles

Edge Computing and AI in Manufacturing

How to Choose the Best Industrial Small Form Factor PC

Acquiring Accurate Measurements in Manufacturing with Mate Gauge

More about OnLogic

Featured Product