Using AI to Solve the "Execution Gap" in Manufacturing

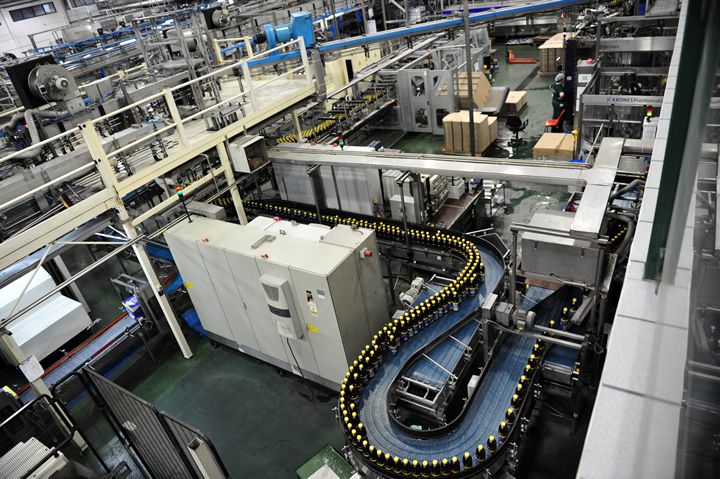

Max AI doesn't just bridge the execution gap - it sets a new standard for modern manufacturing. By acting in real time - watching, thinking, and doing - it removes the friction and firefighting that once consumed operators, supervisors, and planners.

The Library of Machine Malfunctions and Changing the Factory-Worker Relationship

The goal from day one was clear: build the definitive source of industrial reliability knowledge, and open it up to empower teams everywhere to shift from reactive troubleshooting to proactive control.

PILLARS OF TOMORROW - A hopeful vision of Government, Technology, and Human Dignity in harmony

For centuries, visions of the future have been dominated by dystopian warnings - cautionary tales of power gone wrong. Five Pillars of Tomorrow offers an alternative: a governance model where transparency, collective wisdom, and advanced AI safeguard human dignity.

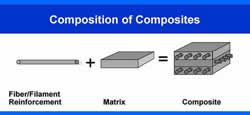

Comprehensive Guide to Composite Materials and Simulation

Composite simulation is crucial because it lets engineers explore designs, optimize performance, and spot failures digitally, saving tons of time and money compared to physical testing. It's challenging due to anisotropy, modeling delamination, and high computational cost.

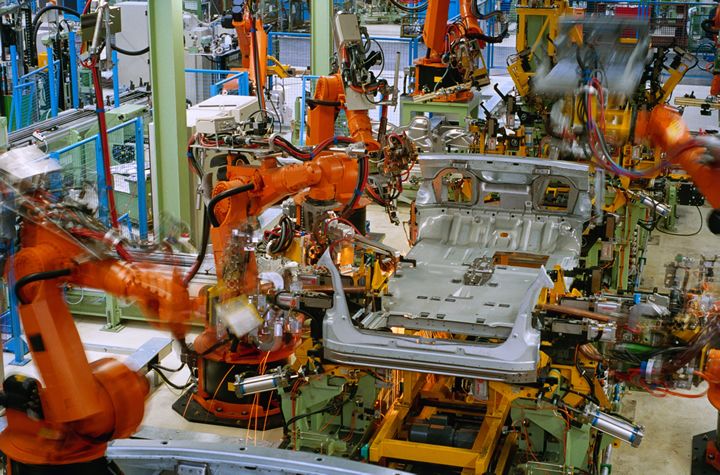

The Promise & Risks of Physical AI's Self-Optimizing Factories & Human-AI Teaming

Physical AI is the difference between an algorithm that predicts a machine failure and an intelligent robot that can physically inspect the machine, identify the fault, and adapt its operation to prevent a shutdown.

Key Considerations for Maximizing Manufacturing Efficiency

It's true that advanced simulation tools have helped improve the efficiency and effectiveness of robotic workcell design and path planning, but it still remains an incredibly time consuming process.

Maximizing Operation Efficiency through Manufacturing Processes

Cross-functional collaboration isn't just helpful, it's the backbone of a smooth new product introduction. You can have the best design on paper, but if engineering, operations and supply chain aren't aligned from day one, you're setting yourself up for late-stage surprises.

Talking PACK EXPO Las Vegas with Encoder Products Company (EPC)

We're featuring live demos of our newest encoders, including the LP1 Accu-LaserPro™ - a slip-free, high-accuracy laser encoder designed for packaging lines. Visitors will see how EPC encoders reduce downtime, simplify integration, and deliver long-lasting performance.

Driving Supply Chain Innovation Through AI and Process Optimization

AI and data analytics are game changers for the manufacturing industry's demand and shop floor agility. My team is currently developing an AI model that identifies irregular demand patterns and updates itself.

BigRep ALTRA 280, the Ultimate High-Temperature Industrial 3D Printer

The ALTRA 280 was engineered to solve a challenge that's persisted for years: reliably and affordably producing large, complex parts in both engineering-grade and high-performance polymers.

Talking PACK EXPO Las Vegas with NORD DRIVESYSTEMS

We're bringing the full package. Our booth will showcase complete drive solutions, including gear units, motors, and VFDs, all designed for high-volume, high-throughput environments. A highlight will be the launch of a new hygienic, caustic washdown solution.

Prioritizing Network Investment in Manufacturing

Industry 4.0 is driving major gains in efficiency, automation, and innovation. But there's a flip side: That progress depends on fast, secure, always-on connectivity. Manufacturing, in particular, is an interesting case study.

Talking PACK EXPO Las Vegas with maxon and Parvalux

As the packaging industry continues to evolve, maxon and Parvalux remain committed to delivering motion solutions that are not only precise and reliable but also adaptable to the dynamic needs of modern automation.

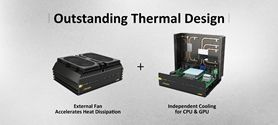

Computers for Edge AI, Machine Vision, and Industrial Automation Applications

The market demand for solutions that combine high performance, compact size, and high reliability is rapidly increasing, especially in harsh environments such as smart manufacturing.

Common Misconceptions Manufacturers have about AI

With over 25 years of experience advising mid-market companies, Ghori provides a grounded yet progressive-looking take on where manufacturers should focus, what misconceptions to avoid, and how to get started without overhauling everything.

Records 1 to 15 of 173

Featured Product

MRPeasy - ERP for Small Manufacturers That Delivers Results

Always know what you have in stock and what you'll need to fulfill orders. Never forget to order parts on time or fail to notice a late delivery from your vendor. Easily create manufacturing orders and schedule them automatically according to resource availability or delivery deadline. Generate accurate cost and lead time estimates and provide customers with quick quotes. Receive notifications when orders are late or inventory levels reach a critical point. Ensure seamless communication between sales, production, warehousing, procurement, administration, and finance. Integrate with popular accounting, CRM, and e-commerce apps. MRPeasy is an ERP software for small manufacturers that gives you all that and more. Our users report a 54% average improvement in the overall performance of their business and a 42% increase in on-time deliveries. Try for free, no credit card needed.

Manufacturing and Automation - Featured Company

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.