The Data Imperative for Smart Microfactories: Enabling Real-Time Agility and Resilience

Understanding End-to-End Configuration: A Primer

Understanding End-to-End Configuration: A Primer

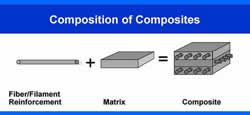

Comprehensive Guide to Composite Materials and Simulation

Comprehensive Guide to Composite Materials and Simulation

Maximizing OEE with Smart Selection of Electric Linear Actuators

Maximizing OEE with Smart Selection of Electric Linear Actuators

Building a Culture of Team Performance at Paramount Machine with Production Monitoring

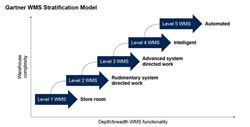

How Gartners 10 Dimensions of Warehouse Complexity can Transform your WMS Strategy

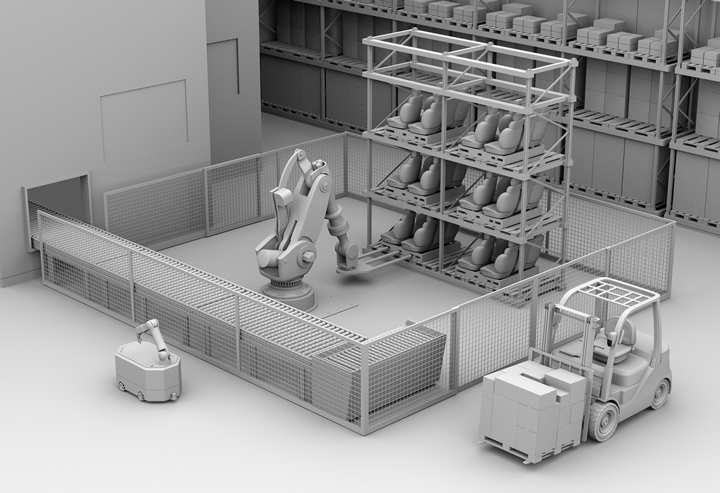

How Automation is Revolutionizing Pipe Fabrication Amid Labor Shortages and Rising Competition

How Automation is Revolutionizing Pipe Fabrication Amid Labor Shortages and Rising Competition

The Promise & Risks of Physical AI's Self-Optimizing Factories & Human-AI Teaming

The Promise & Risks of Physical AI's Self-Optimizing Factories & Human-AI Teaming

IDS: See. Align. Place.

Top 5 AI-Powered Capabilities to Look for in a WMS Vendor

Records 31 to 45 of 20076

First | Previous | Next | Last

Featured Product