Top 5 Questions to Ask When Evaluating IIOT Technology Solutions

5 Ways You Can Improve Your Manufacturing Operations with a Data-First Strategy

Smart Manufacturing - A Layered Approach to Digital Transformation

Machine Health Is the Key to Fully Realizing Industry 4.0 - and Moving Beyond

Digital Insights: Improving Collaboration Across Sites and Global Teams

The Missing Link in Industry 4.0's Connectivity Chain - Overcoming IIot Deployment Challenges Through eSIMs

Service buses and their impact on digitalization

Sustainable manufacturing at the edge

Major IoT Trends to Expect in 2022

2022 Manufacturing Predictions from iBASEt

Increasing Rural Broadband Can Help Rural Manufacturers Compete

How Manufacturers Can Invest in IoT

It's time for change - Technology essential to tackle climate change

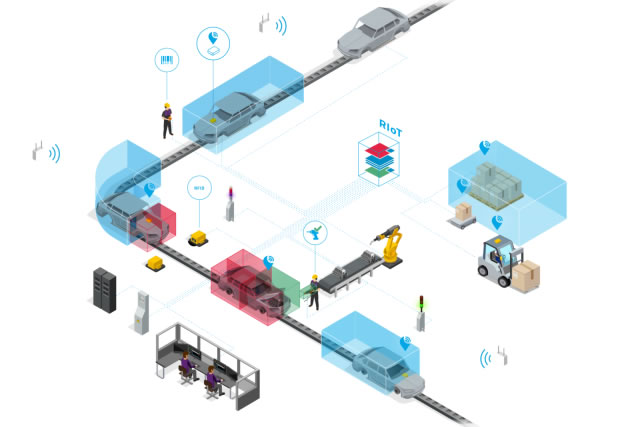

Location-Based Automation- Why a Digital Twin of Moving Things is the Missing Piece for Successful Industrial Automation

MQTT and the Purdue Model Work Together for IIoT Security

Records 16 to 30 of 245

First | Previous | Next | Last

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

Manufacturing and Automation - Featured Company

.jpg)

.jpg)

.jpg)

.jpg)

.png)