Laying the groundwork for smarter manufacturing - Enhancing factory foundations for reduced downtime, more efficient production

From Legacy to Leadership: Building the Manufacturing Company of Today

Transforming manufacturing growth and efficiency with AI translation

Innovation means also taking risks

How to Build a Proactive Obsolescence Management Plan for Critical Components

Adjusting M&A Strategies in Response to Changes in Global Trade Policies and Tariffs

MES Implementation Strategies for Cost Savings and Improved Reporting

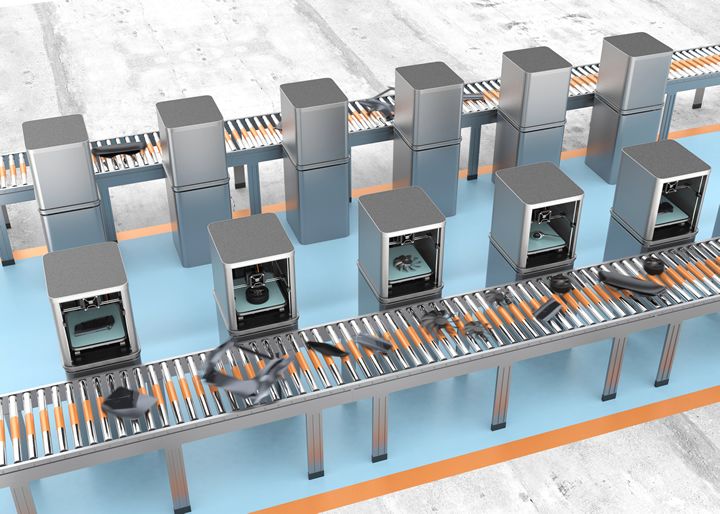

How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

Pricing Optimization for SMB Manufacturers

Dealing with the Aftermath of M&A via Configuration Management

Bridging the Gap: Overcoming the Barriers to Manufacturing Digitization

BOM Management Expert Guide for Growing Manufacturers

Protecting Your Bottom Line: Financial Strategies for Automation Failures

Enhancing Operational Visibility with MOM & MES Synergy

5 Emerging Pain Points in the Manufacturing Supply Chain and How to Preempt Them in 2025

Records 16 to 30 of 269

First | Previous | Next | Last

Featured Product

Rapid Prototyping with the Modular Motor Series

Manufacturing and Automation - Featured Company

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)