PILLARS OF TOMORROW - A hopeful vision of Government, Technology, and Human Dignity in harmony

For centuries, visions of the future have been dominated by dystopian warnings - cautionary tales of power gone wrong. Five Pillars of Tomorrow offers an alternative: a governance model where transparency, collective wisdom, and advanced AI safeguard human dignity.

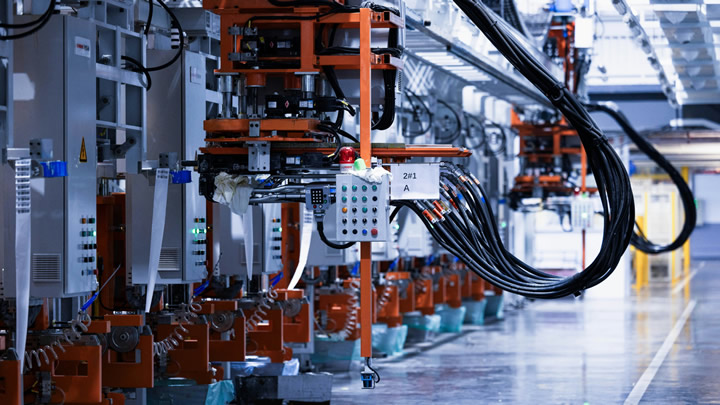

Sensing the Shift: Trends in Smart Industrial Automation

Cutting-edge robotics, sensors, edge computing, IoT and more are at the forefront of smarter manufacturing, bringing together the technology, infrastructure and innovation that power modern automation.

Shaping Company Strategy with Evolving Technology: A 2025 Preview

From the emergence of domain-specific language models to the adoption of AI-related tools and the evolution of the Industrial Metaverse, the upcoming year promises transformative innovations that will redefine global industrial competitiveness.

Factories of the future - What will manufacturing facilities look like in 2044

The landscape of manufacturing is set to evolve dramatically over the next two decades, as cutting-edge technologies redefine the way we produce goods. To envision what the future may look like, we do not need to rely solely on idle speculation.

What's in store for 2024: Top 5 industry trends

The manufacturing industry is undergoing significant changes due to the swift advancement of technology and evolving global dynamics.

How 3D Printing Is Changing the World

In this blog, Knight Optical, the leading supplier of optical components for a wide range of industries (including the 3D printing sector), runs through the most impressive innovations in the world of 3D printing

Top Article from 2019 - Can a 3D Printer Build a Rocket?

NASA has successfully tested its first rocket engine component made through 3D printing. The 3D printed component produced a breathtaking 20,000 pounds of thrust.

What is MXT? (Metering Extruder Technology)

Article from BigRep. As FFF extrusion technology reaches the peak of its development cycle, it becomes less likely that the technology's quality will meaningfully improve. Additive manufacturing must be rethought from its foundation.

Specialty Materials for 3D Printing

Specialty materials that have different mechanical, thermal, chemical, temperature, and conductive properties will continue to enable use cases where designs can be further optimized through the specification of specialty materials that best suit the part requirements.

Electrostatic Discharge (ESD) Safe Materials for 3D Printing

There are three primary uses for ESD safe plastics: electronics manufacturing (e.g. ESD safe jigs and fixtures for printed circuit board manufacturing), materials in a combustible/explosive environment, and nuisance static charge elimination

New 3D Printing Material Builds Extra-Strength Parts

The materials have a non-uniform, crystalline structure, making components built with them much stronger than those built using a standard uniform lattice structure. So much stronger, in fact, that they can withstand seven times the amount of energy ...

Who's Afraid of the Big Tall Build?

Metal AM gives engineers the opportunity to design higher performance parts with a much simpler manufacturing workflow than traditional manufacturing (think: rocket engines).But, in many cases, taller and larger parts will be no-bid or priced too high for the market.

Thermoplastic Extrusion 3D Printing

This new technology makes it possible to print five times faster - with greater precision and quality - than current extrusion speeds. MXT® establishes a clear separation between filament feeding and melting and molten extrusion...

KeraCel, a World Leader in Solid-state Lithium Ion Batteries, Announced a Breakthrough in its Multi-material Ceramic Battery Using its Proprietary 3D Printing Technology

KeraCel is developing its ceramic solid-state batteries using proprietary additive manufacturing 3D printing technology resulting in unique monolithic structure. The unique structure allows for greatly increasing battery energy density, and producing safer and longer lasting

3D-Printing File Formats Must Evolve with the Industry

One of the first trends driving change is 3D printings transition from prototyping to commercial-grade production, combined with the increasing popularity of metal as a printing material.

Records 1 to 15 of 70

Featured Product

Model TR1 Tru-Trac

The Model TR1 Tru-Trac® linear measurement solution is a versatile option for tracking velocity, position, or distance over a wide variety of surfaces. An integrated encoder, measuring wheel, and spring-loaded torsion arm in one, compact unit, the Model TR1 is easy to install. The spring-loaded torsion arm offers adjustable torsion load, allowing the Model TR1 to be mounted in almost any orientation - even upside-down. The threaded shaft on the pivot axis is field reversible, providing mounting access from either side. With operating speeds up to 3000 feet per minute, a wide variety of configuration options - including multiple wheel material options - and a housing made from a durable, conductive composite material that minimizes static buildup, the Model TR1 Tru-Trac® is the ideal solution for countless applications.

Manufacturing and Automation - Featured Company

BigRep

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep ONE opens the gateway to a new dimension of 3D printing and 3D manufacturing, while the BigRep STUDIO allows fast and precise large-scale 3D printing. From furniture to vehicles to robotics, we think everything is possible. We want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of our 3D printers.

.jpg)

.jpg)