Use Reliable Isolation ADCs to Effectively Control Three-Phase Induction Motors

Three-phase induction AC motors produce mechanical power for almost 80% of industrial applications by providing extremely high efficiency and environmentally rugged characteristics. Effective control of these motors is needed to tackle heavier load problems .

Intelligent Motors Equipped with Microcomputers

The idea of using built-in computers to control motors without the aid of external equipment is not a new one, but it has taken until now for computers with the level of performance necessary to control motors in real-time to become small and cheap enough for this idea to become reality.

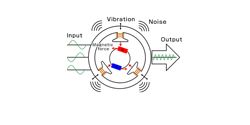

The 6 Latest Trends in Direct Drive Motor Technology

Despite the maturity of the machine tool industry, allowing for many advancements in engineering design over the span of decades, a machine is still limited by what the builder is able to implement.

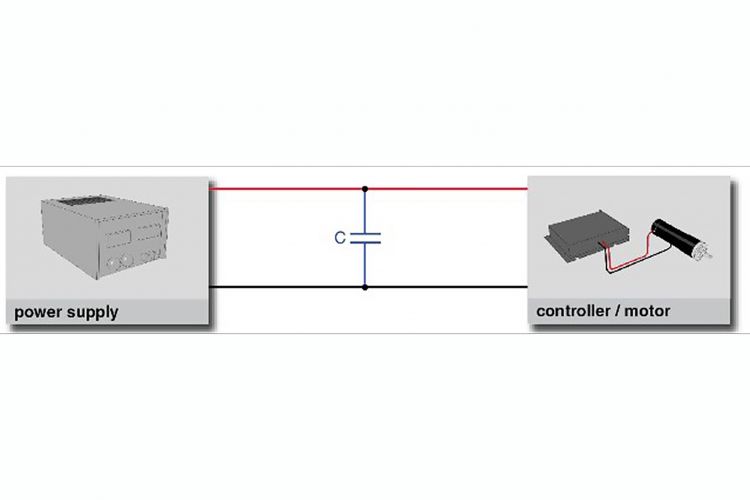

Measures to Cope With Reversed Energy

A proper choice of an industrial power supply can already solve problems and error messages caused by reversed energy.

Which Motor Is Right for Your Manufacturing Process?

Several different types of electric motors have been developed to address the needs of various manufacturing processes. Lets examine some of the most common types of electric motors and their strengths within the industry.

How to Choose a Controller for Motor Applications

For many engineers, pulling all the parts together - the controller with embedded or separate algorithms, the drivers, and the MOSFETs - is a multidisciplinary task, and one for which they dont want to "reinvent the wheel."

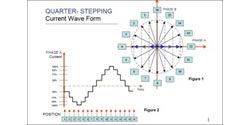

Inaccuracies with Motors and Drivers: Who is the Culprit?

Is Your Step Motor and Driver Contributing to the Inaccuracy of Your System?

High Efficiency Motors

To understand the concept of high efficiency motors, you must first know how to calculate efficiency and the losses associated with the motor components themselves.

High-Performance, High-Speed Motor Breathes Life into Ventilators and Respirators

New motor technology has changed the way modern ventilators and respirators are designed, making them quieter, more compact and more efficient.

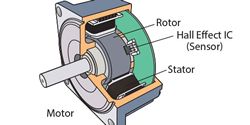

Brushless DC Motors vs. Servo Motors vs. Inverters

We have put together a summary (Table 1) that compares these three technologies in a simple to understand format.

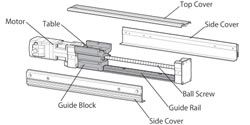

Method for Calculating Moment Loads on Linear Actuators

With the actual equipment, there are various kinds of equipment conditions and driving conditions for electric actuators and cylinders and thus, it is very difficult to explain all the operating conditions.

Records 1 to 11 of 11

Featured Product

ResinDek® TRIGARD® ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC® (www.resindek.com) created the TriGard® ESD Ultra finish for its ResinDek® engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Manufacturing and Automation - Featured Company

FAULHABER MICROMO

Since 1961, FAULHABER MICROMO has partnered with OEMs to deliver high precision, high performance, custom micro motion system solutions to markets such as medical, robotics and automation in North America. FAULHABER MICROMO's tradition of innovation started decades ago in Germany. The groundbreaking invention of the FAULHABER coreless winding started it all for a market that produces millions of motors today.

How can the FAULHABER MICROMO team help you deliver your next innovation to market first?

Learn more about MICROMO's solutions for the most demanding applications, our diverse motion products and technologies, online ordering, Engineering and R&D teams, Clean Room Assembly, Machining Center and other services at our Clearwater, FL facility at www.micromo.com.