The idea of using built-in computers to control motors without the aid of external equipment is not a new one, but it has taken until now for computers with the level of performance necessary to control motors in real-time to become small and cheap enough for this idea to become reality.

Intelligent Motors Equipped with Microcomputers

Intelligent Motors Equipped with Microcomputers

Contributed by | Nidec

Responding to this trend of rapid technological advancement, Nidec has previously adopted the use of microcomputers for vector control and for replacing stepping motors with brushless DC motors. We now seek to take this concept one step further with our intelligent drive technology capable of actively monitoring and controlling a wide range of motor parameters.

.jpg)

Computers are Rapidly Becoming Increasingly Smaller and Cheaper in Accordance with Moore's Law.

Overcoming Numerous Design Challenges in Motor Control, such as Realizing High-Precision Servo Capabilities, Maximum Efficiency Operation, Ultra-High-Speed Rotation, Soft Starting, Overload Monitoring and Vibration Suppression

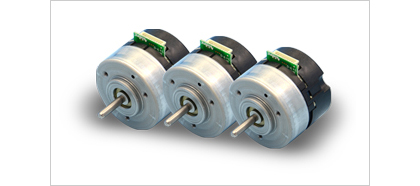

Nidec Develops Intelligent Computers Embedded with Compact High-Performance Microcomputers.

Microcomputers embedded in motors ensure that the motor is running in its optimal operating state by monitoring voltage, current and rotational frequency to estimate the load on the motor. They can also be used for soft starting, overload monitoring, precise torque adjustments and positioning as well as many other advanced functions. One of the benefits of built-in microcomputers compared to external electronic control units is the ability for control-parameters to be adjusted in real-time with very high responsiveness to load fluctuation, keeping self-excited vibration associated with delays in control to a minimum. Furthermore, this new technology also removes the need for flywheels and reducers, previously used to absorb load fluctuation—making for smaller and lighter modules that provide even more value to assembly manufacturers.

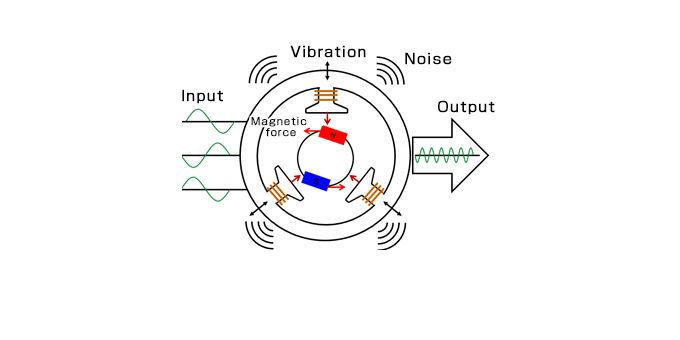

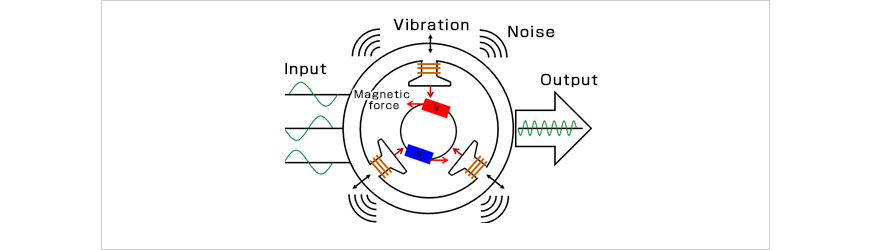

Electromagnetic noise and vibrations occur as a result of discrepancies in input and output. Using intelligent control to eliminate these discrepancies leads to reduced electromagnetic noise and vibrations and improves the efficiency of the motor.

Motors, Drives, Sensors—All of the Necessary Core Competences Gathered in One Company-Group

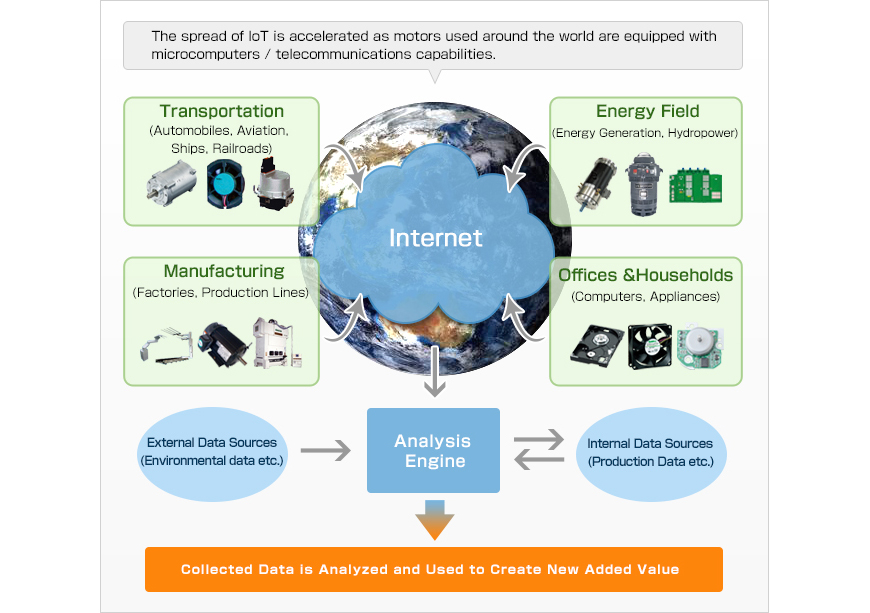

Although the advent of intelligent motors has been delayed in the past by limitations in computer technology, Nidec has been able to succeed in developing these motors ahead of the competition. The reason for this is that the capabilities of our company group extend beyond motors to encompass drives, sensors and other assets necessary for intelligent motors. Another of our advantages is our centralized research facility, independent of our business divisions, where basic research is conducted on a long-term basis to build a strong technological foundation that can support all of our business divisions. As motors become more and more intelligent they will increasingly function as sensors that process information about their surroundings. This information can then be collected and analyzed by IoT systems to create new added value. At the Nidec group, we strive to create even more sophisticated and intelligent products with our eyes set on the possibilities of tomorrow.

By using IoT to collect and analyze data, it becomes possible to understand the characteristics and trends of the different fields that motors are used in. Intelligent motors have the potential to make a very large impact on our society.

If you like this article you may like "Predictive Analytics vs Machine Learning"

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Featured Product