AI for Product Data Management: A Key Component for Smarter Manufacturing

AI improves data quality by reducing errors and inconsistencies introduced by manual intervention. Manual errors may not seem like a huge deal, but they can easily disrupt time-to-market or channel accuracy.

Driving Performance Improvement on the Shop Floor with Production Data

One of my favorite customer lines is, "I need parts, not charts." And that really captures what Datanomix is about: helping manufacturers solve real business problems by clearly showing what's happening on their shop floor.

2025 Top Article - The Rise of AI in Manufacturing to Collect and Use Data

While AI and machine learning systems typically require around two years to collect enough data to reach their full potential, manufacturers can start seeing benefits almost immediately with basic analysis tools and dashboards.

The Future of IoT Analytics: How AI and Big Data are Changing the Industrial Sector

Imagine trying to keep track of everything happening in a giant factory, where robots build cars, sensors check the temperature, and cameras inspect for defects. Without a system to connect all that information, it would be chaotic.

Boosting global competitiveness through digitalization and standardization

European industries are under pressure. High labor costs and a growing shortage of skilled workers make it challenging to compete globally. The solution? Digitalization and standardization.

From Simple Fixes to Advanced AI: A Small Manufacturer's Guide to Industry 4.0

You might be aware that Industry 5.0 is aspirational for even the manufacturing who's who and while the jury is still out on what exactly the goal of 5.0 is, many experts observe that Industry 4.0 is far from complete

Why Cloud-Based EDI Is Imperative for Manufacturing

An effective EDI in manufacturing must be as agile, accurate and secure as leading manufacturers themselves. The only way to achieve that is to use a cloud-based alternative to conventional solutions.

How Remote Industrial Operators Will Dominate the AI Race

Companies that secure data ownership today are the ones who will lead tomorrow or, in Olympic terms, will earn gold in the AI race.

What is "Platform as a Service" and How Does it Improve Efficiencies in IIoT Ecosystems?

With each new IIoT device brought to market, manufacturers spent untold amounts of time and money making it live up to its potential. Time and again, they were building and rebuilding the same technology to enable data-based decision making, miles away from the device itself

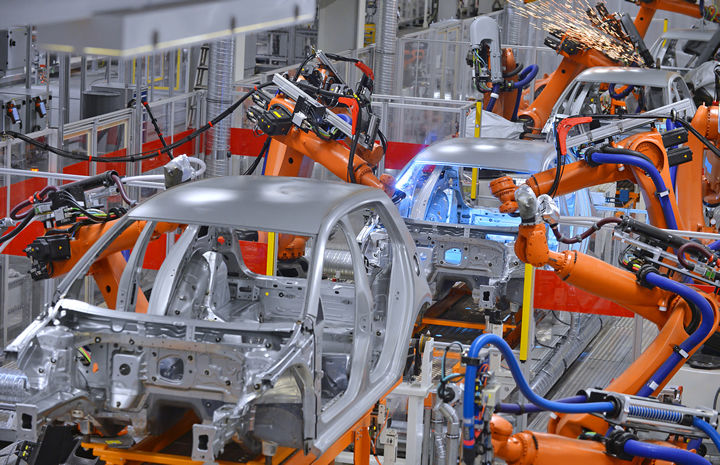

7 Reasons Cloud Data is Driving the Future of Auto Manufacturing

Storing and analyzing auto manufacturing data in the cloud has several advantages automakers can't afford to miss. Here's a closer look at these benefits and why cloud data will drive the future of auto manufacturing.

The Data Revolution Is Transforming Manufacturing-Don't Fall Behind

Getting a robust, firing-on-all-cylinders data operation is a far less labor-intensive process than many seem to suspect, and the dividends it yields invariably outpace whatever effort is expended on getting it off the ground.

Why Data Contextualization is Critical During the Digital Transformation Era

Data is the critical driver of change, but even the highest quality data can't drive change in a vacuum. Simply gathering and accessing data is not enough-manufacturers must leverage it in context to make decisions that enhance value in times of digital transformation.

Data Guys Versus Production Pros - Who is the Best Person to Train AI Programs for Defect Detection?

Artificial intelligence has the potential to deliver game-changing results for quality inspection and defect detection. However, until now the process of training the model has proven problematic.

Giving Second Life to Legacy Systems Through the Industrial Internet of Things

Due to the fact that manufacturing and IT systems have historically developed in parallel, they cannot communicate by default, which forces companies to struggle with compatibility issues when performing digital transformation.

Industrial Analytics: A Catalyst for Sustainability in Manufacturing

There was a time when the average manufacturing facility was a kind of black box: you could measure inputs and outputs, and roughly gauge other metrics, but precision was a pipe dream. That's changed drastically in recent decades, with the advent of the IIoT

Records 1 to 15 of 42

Featured Product

Rapid Prototyping with the Modular Motor Series

Quick to configure. Quick to build. Quick to deliver. Parvalux understands the importance of getting product in the hands of customers quickly and efficiently. The Modular Range does just that allowing customers to configure their own solution, selecting motor and gearbox, adding encoders and brakes to create a solution perfectly suited for their specific applications such as conveyor belt systems, picking systems, parcel sorting equipment, pallet shuttles and automated storage and retrieval systems (ASRS). Read our modular range guide for specifics.

Manufacturing and Automation - Featured Company

PI USA (Physik Instrumente)

PI is a privately held company that designs and manufactures world-class precision motion and automation systems including air bearings, hexapods and piezo drives at locations in North America, Europe, and Asia. The company was founded 5 decades ago and today employs more than 1700 people worldwide. PI's customers are leaders in high-tech industries and research institutes in fields such as photonics, life-sciences, semiconductors and aerospace.

.jpg)

.jpg)

.jpg)

.jpg)