Case Study: Achieving a High-Risk Systems Overhaul on an Accelerated Schedule

When TGES America, Ltd. (hereinafter TGES America) needed a critical overhaul of the complex control system and instrumentation for the central utilities plant (CUP) of a specialty materials manufacturing plant, they turned to aeSolutions, a Siemens Solution Partner.

Control System Migrations | Managing Scope, Schedule, Budget

Give yourself a pat on the back, you've successfully navigated the tasks of providing procurement specification and selecting a vendor for your control system migration project. In part four of this series, we will be exploring scope, schedule, and budget.

Repurposing and Extending the Life of Aging ATE Systems

ATE stations are specifically engineered to validate the functionality of the units being tested. A substantial investment in testing equipment is necessary, and then"¦ everything changes. Government contracts may not be renewed or could be entirely terminated.

Mitigating Project Risks through Front-End Loading for Control System Migrations

FEL is all about minimizing the risk: The cost risk, the schedule risk, and the scope risk for any capital undertaking. Early in a project, the cost impact of changes is low, but it increases, often drastically, in later stages.

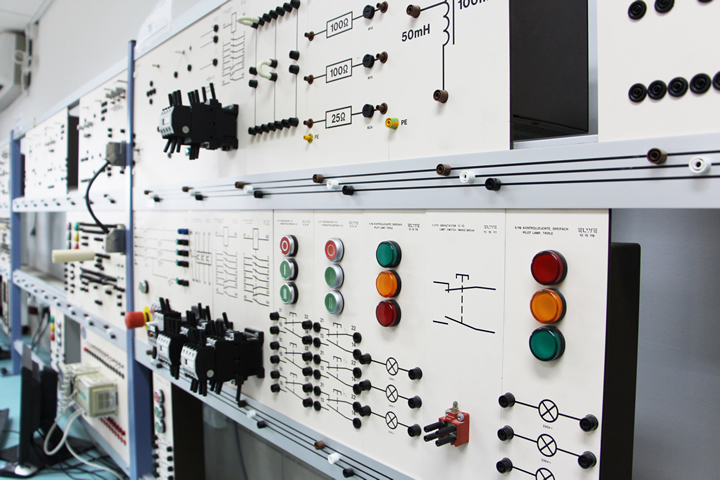

Human Machine Interface (HMI) and its Importance in Industrial Automation

Human Machine Interface; in short "HMI" is the means by which an operator can interact or control the machine or the entire process. It all started with hard wired push buttons and indicator lights on a control panel.

Why Combining Your HMI & PLC Is the Smarter Move

While PLCs control mechanisms, electronics, and other low-level devices, HMIs empower operators with visualization and touch controls. Together, HMIs and PLCs pave the way for efficient and flexible industrial workflows.

Achieving Plant Resiliency - Automation Technologies That Can Make Production More Effective

According to a Deloitte global survey, 94 per cent of executives in industrial companies consider digital transformation a top priority, but only 14 per cent believe their factories are ready for this big change.

Using Biometrics in Industrial Control Systems

The State of Industrial Cybersecurity Report 2018, from the Kaspersky Lab, found that 54 per cent of respondents who had experienced a cyber-attack on their industrial control system (ICS) noticed damage to their products or services. Industrial control systems are critical to business success, so how can we protect them better?

Records 1 to 8 of 8

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Strain wave gearheads are ideal for use in applications requiring precision motion control and high torque transmission in a compact design. maxon strain wave gearheads are a specialized type of gearhead where precision and compact design are crucial. This type of gearhead is often used in applications in a confined space. With their advanced gear tooth design, maxon's strain wave gearheads provide high efficiency and good back drivability. Typical applications include:

Robotics, Aerospace, Medical technology and Optical systems

.

Manufacturing and Automation - Featured Company

Datanomix

Datanomix empowers manufacturers of all sizes to increase productivity and profitability through its Data-Powered Production™ solutions. Its product portfolio includes Production Monitoring, G-Code Cloud™ + DNC, TMAC AI™, and ToolAnalytix™ - all designed to turn machine data into actionable insights with zero operator input. Headquartered in New Hampshire, Datanomix software analyzes real-time production signals to identify bottlenecks, improve quality, and provide prescriptive coaching to drive continuous improvement. For more information, visit www.datanomix.io.