What Steel and Aluminum Tariffs Could Mean to Steel King and How Those Tariffs Could Impact Everyday Business

Leveraging the Virtual Twin Experience for Decarbonization in the Metals Industry

Automation and advanced technologies boost efficiency

How ERP streamlines lean manufacturing

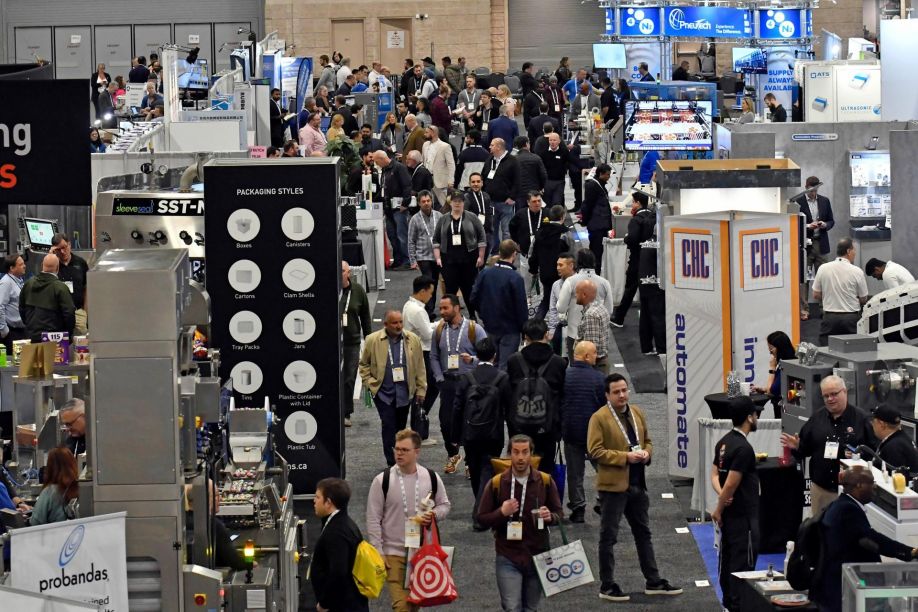

PACK EXPO Southeast 2025: The Future of Packaging & Processing Arrives in Atlanta

Strengthening the Workforce: The Growing Demand for Talent in Manufacturing

AI as Co-Pilot: Empowering Human Leadership in Supply Chains

5 Emerging Pain Points in the Manufacturing Supply Chain and How to Preempt Them in 2025

AI-Powered Additive Manufacturing Transform Production and Supply Chain

5 Steps to Meet the Growing Demand for Automated Warehouses in 2025

The Generative Economy: Imagine Circular Value Chains

For efficient warehouse heating, unit heaters may be the best solution

AI Route Optimization Saves Money, Cuts Fuel Consumption and Provides Faster Delivery Times

Digital Manufacturing's Role in the Future of U.S. Electric Vehicles

Examining the Integration of Hydrogen Fuel Cell Tech in the Manufacturing Supply Chain

Records 16 to 30 of 384

First | Previous | Next | Last

Supply Chain - Featured Product

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)