Linux-based Software for Automation

The Integration of Electrical CAD/CAE for Machine Manufacturing

How CAD Software Is Evolving for Manufacturers

Simulation Design for Rapid Prototyping

Virtual Reality? How about "Virtual before Reality"

An Easy Way to Start Working in the New Generation Ethernet: Time-Sensitive Networking (TSN)

Improve without Change: Extending Your Industrial Assets to Do More with What You Have

How to Optimize Artificial Intelligence in the Manufacturing Industry

Using Open Software in Manufacturing

Understanding the Basics of PLCs

Why Conventional Planning Fails

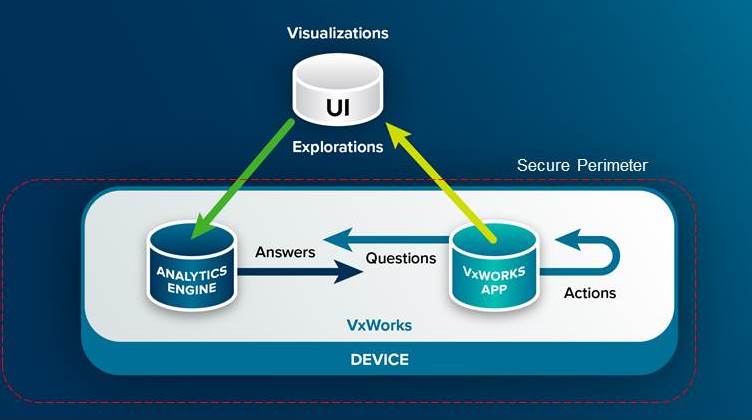

Wind River's AXON Predict Analytics for VxWorks Enables IoT Analytics at the Edge

What is IO-Link

Elon Musk: Robot software will make Tesla worth as much as Apple

Electro-Mechanical Assembly Press Technology Moves Li-Ion Battery Manufacturer A Step Closer To Perfection

Records 16 to 30 of 35

First | Previous | Next | Last

Featured Product

Model TR1 Tru-Trac

Manufacturing and Automation - Featured Company

.png)