How Freight Visibility Is Redefining U.S. Manufacturing Supply Chains

With freight visibility, you can search for alternative sources and routes when shipments hit a snag. You can find the best ways to increase your resources for demand spikes, and you can search for the most cost-effective solutions during demand droughts.

The 'Halo Effect' of Manufacturing Facility Location: Why Smart Manufacturers Are Choosing Locations Near Complementary Businesses

This strategy is not about simple convenience; it's about creating a powerful, mutually reinforcing "halo effect" of shared success, instant market credibility, and profound operational synergy across engineering, tooling, fabrication, and logistics networks.

Why Manufacturers Must Rebuild Their Factories Around the Buyer

Today's generation of buyers expects products built to fit their needs, transparent pricing, reliable delivery, and ongoing support that extends beyond the initial sale.

Why Economic Uncertainty Demands a Real-Time Manufacturing Strategy

Proactive manufacturers now treat economic uncertainty not as isolated incidents, but as ongoing tests of their operational readiness and digital maturity.

Must-Have AI Features in your next ERP: Why AI-Enabled ERP Is a CEO's Best Investment

The next wave of competitive differentiation lies in embedding artificial intelligence (AI) directly within ERP/MIS systems - not as an add-on, but as a native capability driving data, decision-making, and automation across operations.

Organic Soda Producer Implements Traceability System in Just a Few Weeks

Fresh Fizz Sodas from Long Island needed a system that would help them comply with traceability regulations, and found the perfect solution in MRPeasy.

9 Evidence-Backed Predictions for the Next Decade of Auto Part Manufacturing

As the industry navigates the next decade, it will adapt to the digital transformation and the emergence of smart vehicles. Here are nine evidence-backed predictions for the next 10 years of auto part manufacturing.

The Next Industrial Epoch is Here: Why Acting Now is a Strategic Imperative for Manufacturers

The convergence of technological maturity, proven financial returns, and a strategic need for resilient domestic production has created a generational opportunity, and the window to act is now.

"Building for the Surge: How to Prepare Your Factory Storage for Times of Peak Demand"

To truly manage seasonal peaks efficiently and safely, facilities need a storage infrastructure designed to flex with changes in demand, regardless of whether they're seasonal, planned, or one-time occurrences.

10 Common Supply Chain Issues & How to Solve Them

Let's take a look at some of the major global supply chain issues of the past four years, then drill into the most common effects on businesses. You'll be surprised at the number of strategies you can implement to mitigate the risks.

Why Manufacturers Must Balance Proactive Cybersecurity with Verified Recovery

Under more pressure than ever to protect their systems, many organizations are still acting on the assumption that proactive prevention will keep their operations safe and running. In reality, hackers can break through first walls of defense and wreak operational havoc.

Maximizing ROI with Mobile Automation: What the Data Shows

Technologies like autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) are helping companies bring autonomy to material movement more efficiently, safely, and cost-effectively than ever before.

How Collision Awareness Systems Help Meet OSHA Forklift & Pedestrian Safety Guidelines

According to OSHA, approximately 35,000 serious injuries and 62,000 non-serious injuries involving forklifts occur each year in the U.S., many of which are due to poor visibility, blind spots, and uncontrolled intersections in warehouses.

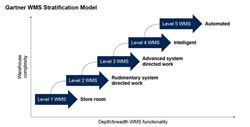

How Gartners 10 Dimensions of Warehouse Complexity can Transform your WMS Strategy

A strong WMS should balance simplicity and depth, offering configurability without extensive custom code, seamless integration with material handling systems, and robust tools for labor management, task orchestration, and automation.

Unlocking the Benefits of a Data-Driven Manufacturing Supply Chain

A data-driven supply chain isn't just about tracking shipments. It's about turning a mountain of raw data: sales figures, inventory levels, supplier performance, even weather patterns, into actionable insights. It allows supply chains to anticipate problems before they occur

Records 1 to 15 of 955

Supply Chain - Featured Product

NORD Delivers Powerful, Reliable Drive Solutions for Demanding Packaging Applications

When you need quality, flexibility and high efficiency, NORD has you covered with complete drive solutions for primary and secondary packaging, end-of-line packaging, and higher-level applications. NORD supports you through the entire life cycle of your drive systems with pre-sales engineering support, online tools, and a global service network. Drive systems for both vertically and horizontally networked technology with all the options for sensor incorporation and integration into the higher-level control system.

Manufacturing and Automation - Featured Company

NORD DRIVESYSTEMS

With four production facilities in the Midwest, on both coasts, and in the South, NORD is prepared to serve you with some of the shortest lead times in the industry. We house extensive component inventory, allowing us to assemble and ship 25% of all standard product orders same or next day!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)