3D-Printing File Formats Must Evolve with the Industry

5 Steps to Preparing for the Future in the Manufacturing Sector

How to Evaluate if a Part Is Fit for Additive Manufacturing?

Powder Handling and Sieving Solutions for the Additive Manufacturing Industry

Best Practices for Production in the Age of Advanced Manufacturing

What Technologies are Transforming Manufacturing

Using Technology to Design Smart Factories

Making a Business Case for Switching to Additive Manufacturing

How to Dodge the Industry-Wide Knowledge Gap

Polymer 3D Prints Used to Protect Costly Metal Parts

Successful Digital Transformation in Industry 4.0 Starts With Human Operators

SME Publishes Second of Three Smart Manufacturing Reports to Encourage Adoption of Emerging Technologies

The Future of Manufacturing is Smart

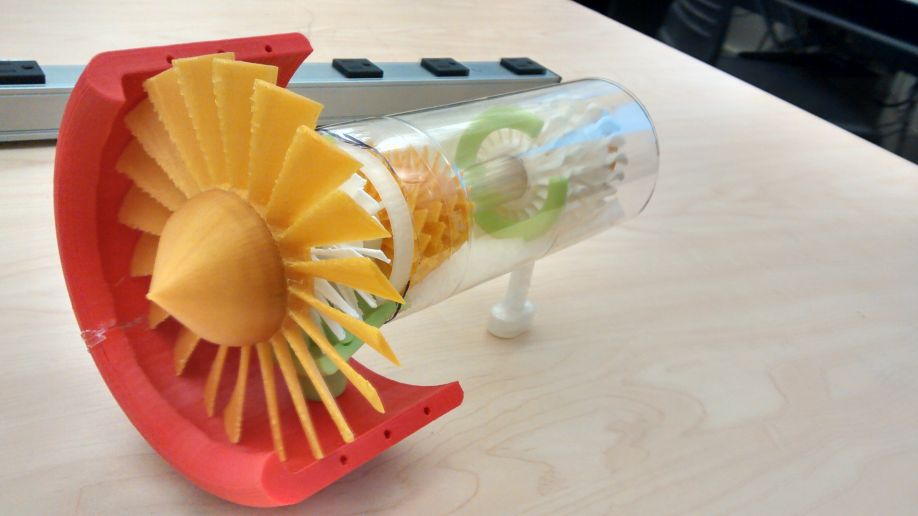

How 3D Printing is Impacting Manufacturing

How Automotive Manufacturers are Utilizing Augmented Reality

Records 31 to 45 of 94

First | Previous | Next | Last

Featured Product

Rapid Prototyping with the Modular Motor Series

Manufacturing and Automation - Featured Company

.jpg)

.jpg)